Loading device for road freight

A technology of roads and conveyor belts, applied in the field of loading devices for road freight, can solve problems such as unsmooth loading and sliding of goods, and achieve the effects of preventing goods from falling, preventing goods from being damaged, and having a high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following is further described in detail through specific implementation methods:

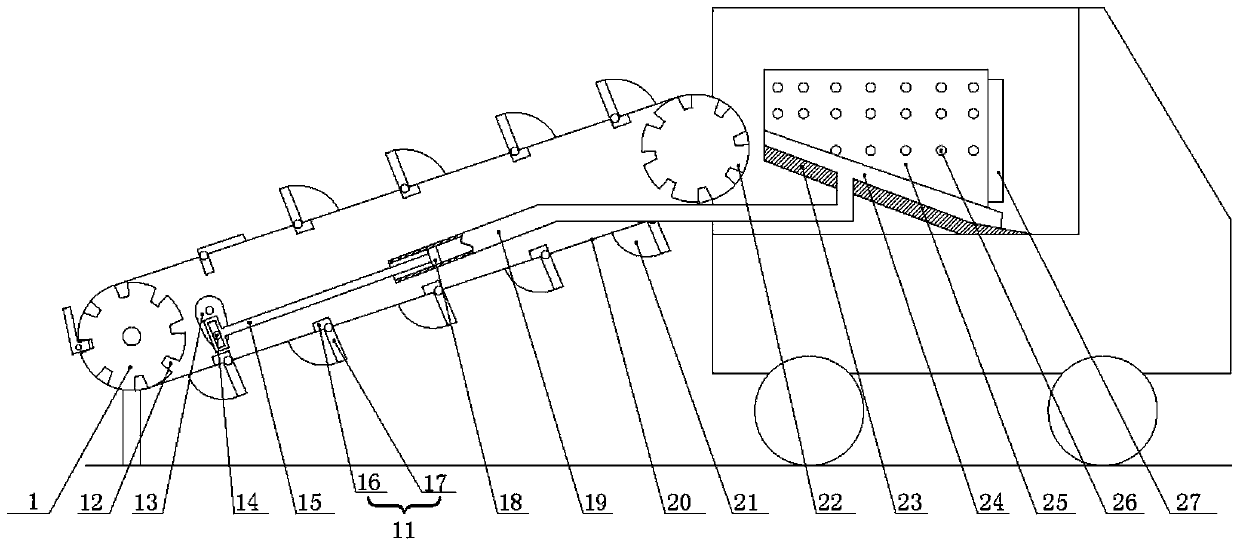

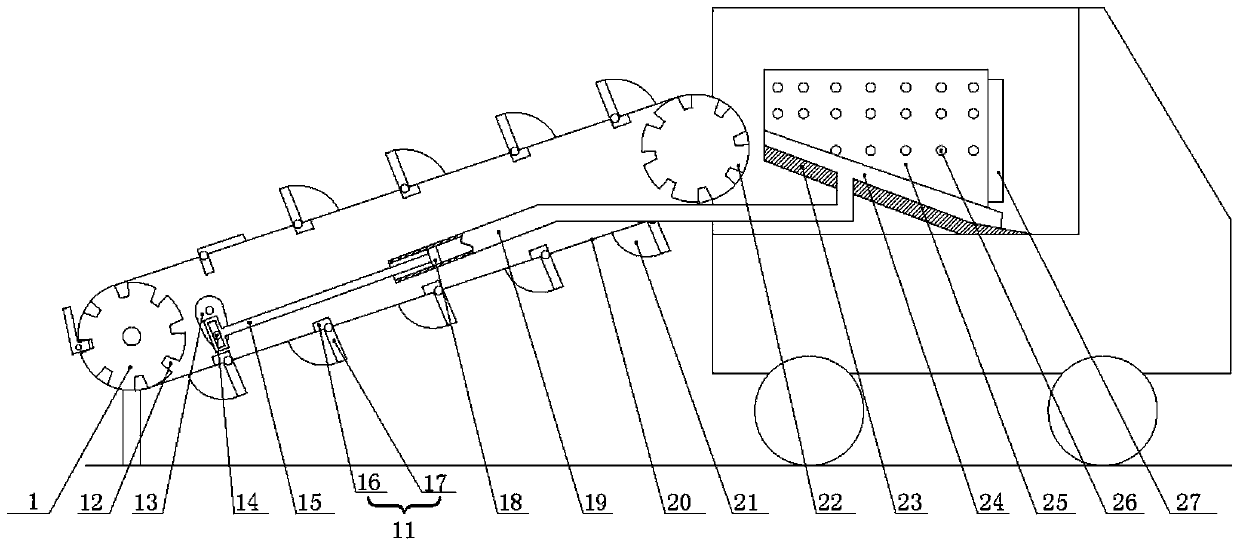

[0021] The reference numerals in the accompanying drawings of the description include: drive wheel 1, support plate 11, draw-in slot 12, cam 13, slide bar 14, T-shaped bar 15, horizontal plate 16, vertical plate 17, piston 18, inflatable tube 19, conveyor belt 20. Elastic cloth 21, driven wheel 22, blanking plate 23, air bag 24, baffle plate 25, dust suction hole 26, slide plate 27.

[0022] The embodiment is basically as attached figure 1 Shown:

[0023] The loading device for road freight of the present invention comprises a driving wheel 1 and a conveyor belt 20, a driven wheel 22 is installed on the upper right side of the driving wheel 1, and a plurality of draw-in grooves 12 are uniformly provided on the driving wheel 1 and the driven wheel 22. The conveyor belt 20 is tensioned on the driving pulley 1 and the driven pulley 22 , and several L-shaped support plates 11 are insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com