Vehicle body bottom assembling heavy load aerial four-belt elevating self-propelling trolley conveying system

A technology of self-propelled trolley and conveying system, which is applied in the direction of track system, trolley crane, hoist, etc., can solve the problems of increased manufacturing cost, extensive positioning, hidden safety hazards, etc., and achieve the effect of stable reliability and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

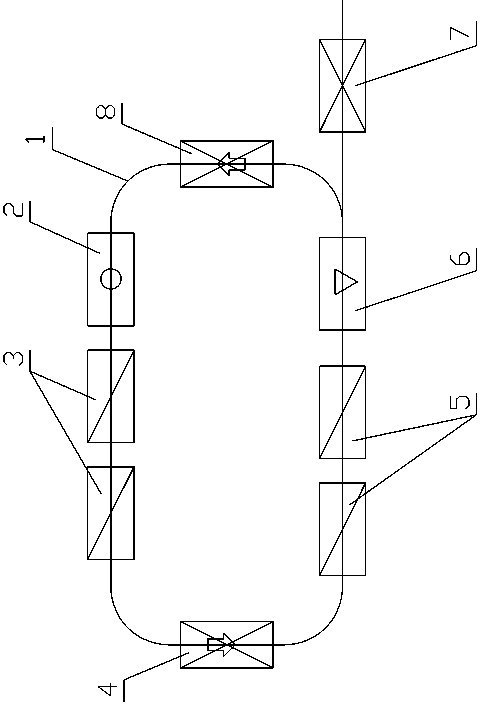

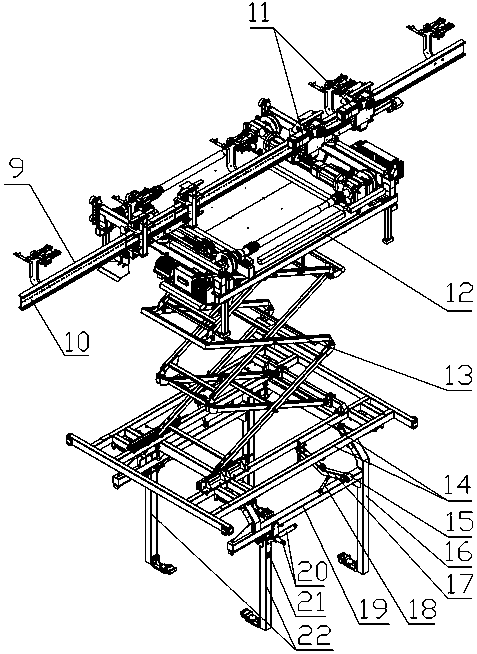

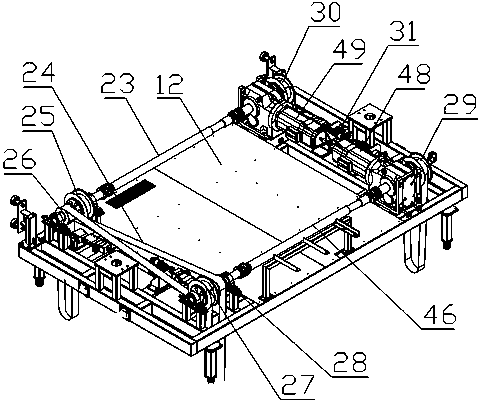

[0028]The present invention is a self-propelled trolley conveying system with four belts in the air for assembling the bottom of the vehicle body with heavy load. It has a circular track 1 set in the air, and the upper station 2, the bottom assembly station A3, and the buffer station are sequentially arranged along the running direction on the circular track. Position 4, bottom assembly station B5, lower part station 6 and spreader hanging leg adjustment station 8, there is also a maintenance station 7 on one side of the lower part station and upper part station, and there are workpieces running on the circular track The self-propelled trolley 12 is laid with a safety two-dimensional code 10 along the way on the circular track, the position information is stored in the safe two-dimensional code, and the body of the workpiece conveying self-propelled trolley is provided with a safety code reading device; the bottom of the workpiece conveying self-propelled trolley body is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com