Workstation for preparing cross-wound bobbin vending machine

A cross-winding bobbin and workstation technology, applied in the direction of thin material handling, conveying filamentous materials, transportation and packaging, etc., can solve the problems of wax body heating, thermal response sensitivity, supporting shell heating, etc., and achieve the elimination of motor heat, prevent overheating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

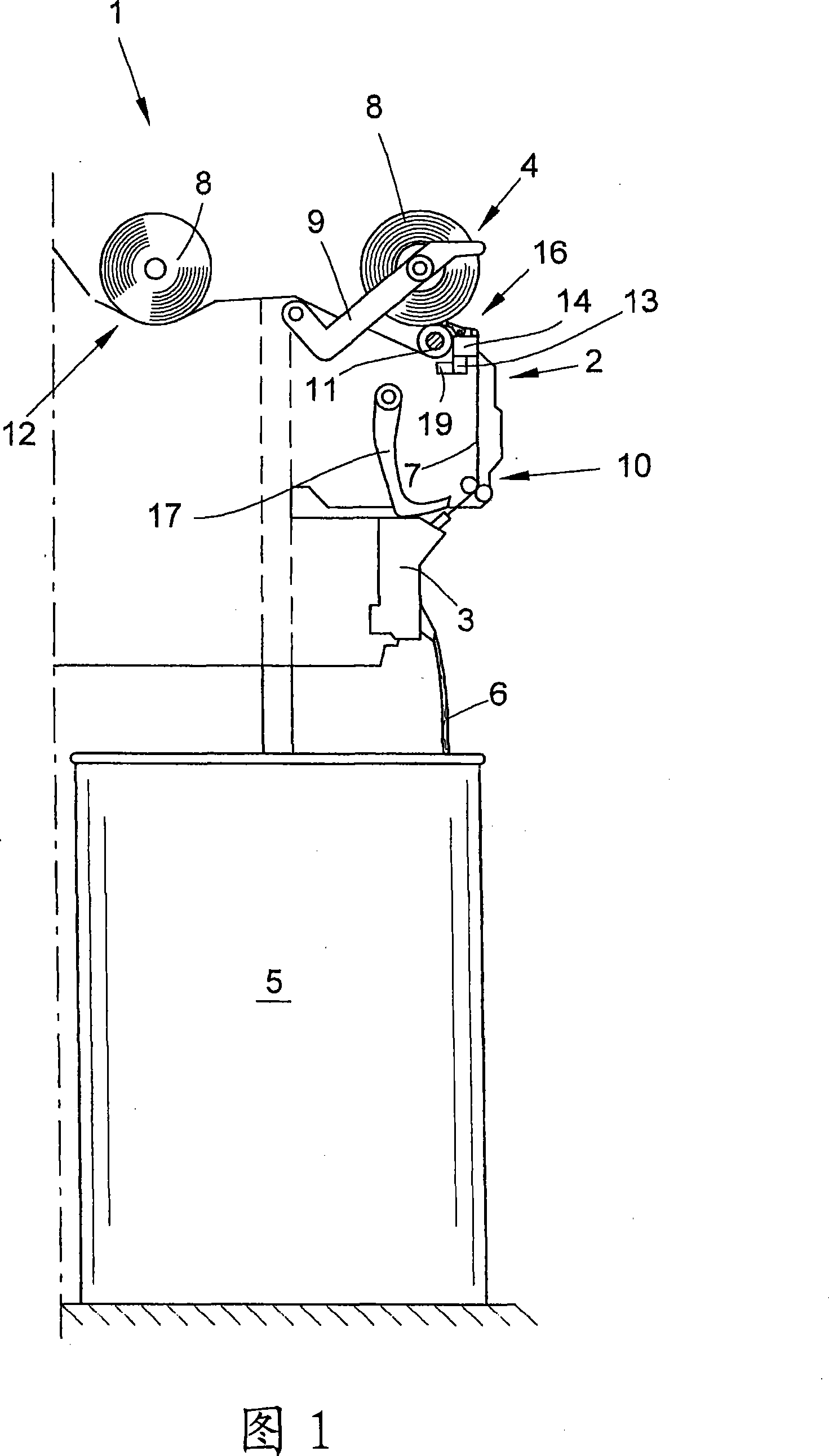

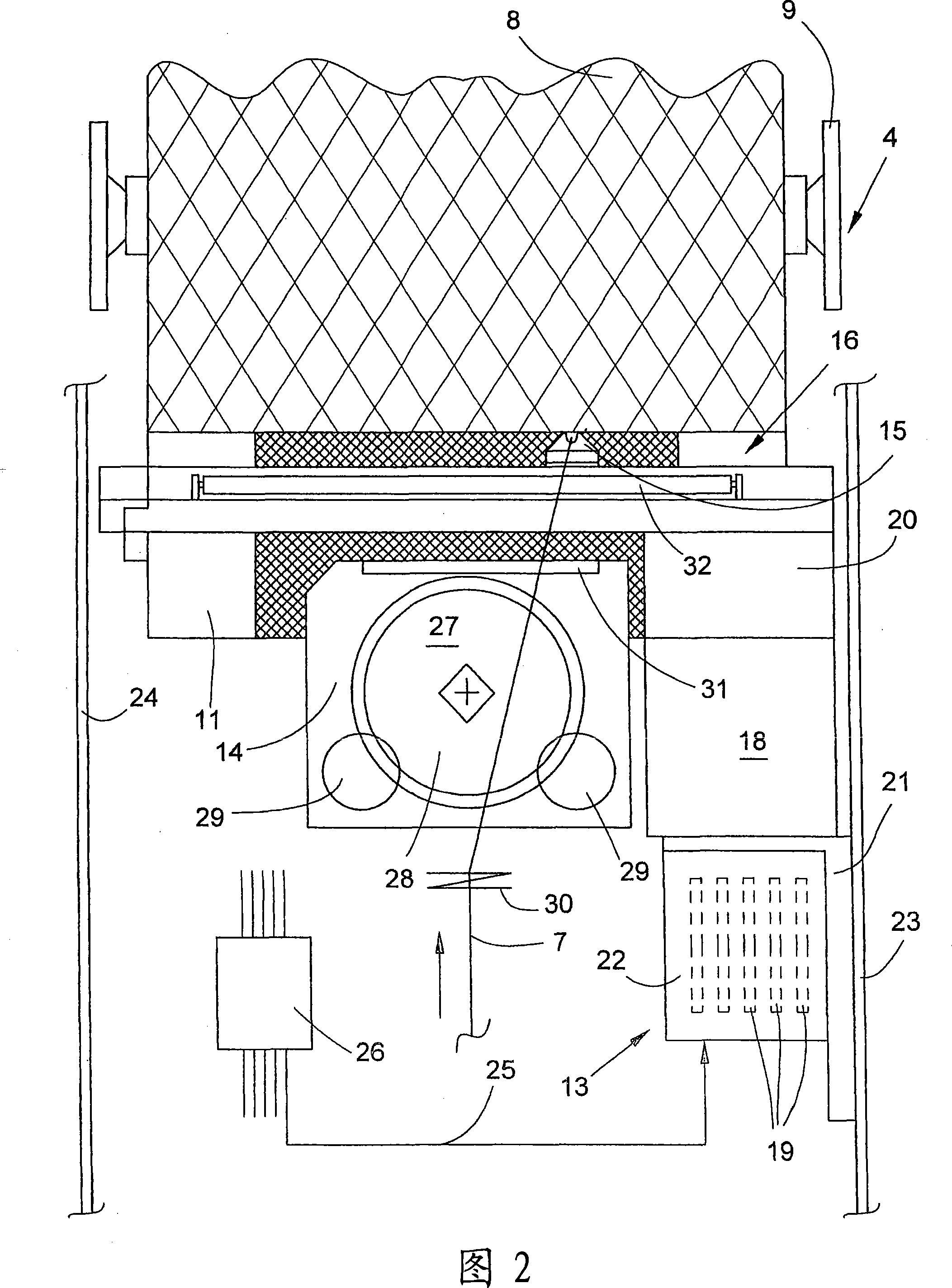

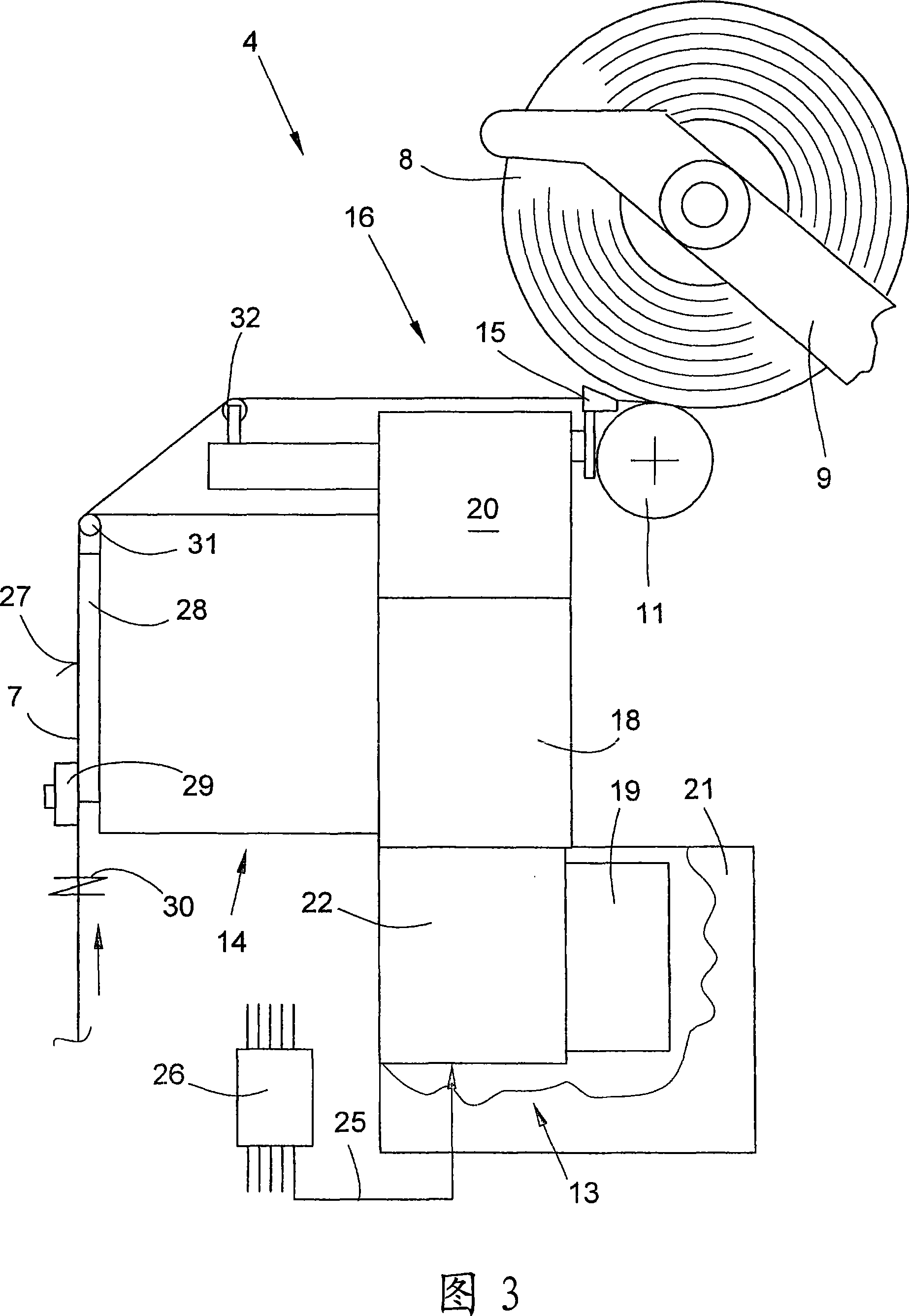

[0028] FIG. 1 schematically shows one half of a textile machine 1 producing cross-wound bobbins, in this embodiment an open-end rotor spinning machine, in side view. As is known, textile machines 1 of this type have between their end frames (not shown) a large number of similar workstations 2 with open-end spinning devices 3 and winding devices 4 therein. In the spinning device 3 , the fiber sliver 6 stored in the spinning pot 5 is processed into threads 7 , which are then wound onto a winding device 4 to form a cross-wound bobbin 8 . The finished cross-wound bobbin 8 is then conveyed, for example via a cross-wound bobbin transport mechanism 12, to a loading station (not shown) provided at the end of the machine. As further shown in FIG. 1 , in addition to the spinning device 3 and the winding device 4 , each workstation 2 also has further thread control or thread handling mechanisms, such as thread extraction mechanisms 10 , suction nozzles 17 and waxing Agency14. The funct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com