A micro-expansion grouting material for tunnel lining vault band mold grouting

A technology of micro-expansion and grouting materials, which is applied in the field of tunnel lining and vault grouting materials with molds, can solve the problems of cracking, low bonding strength margin, and low 7d strength, so as to improve dispersion and stability, improve Freeze-thaw aging resistance, strength, no shrinkage and no cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

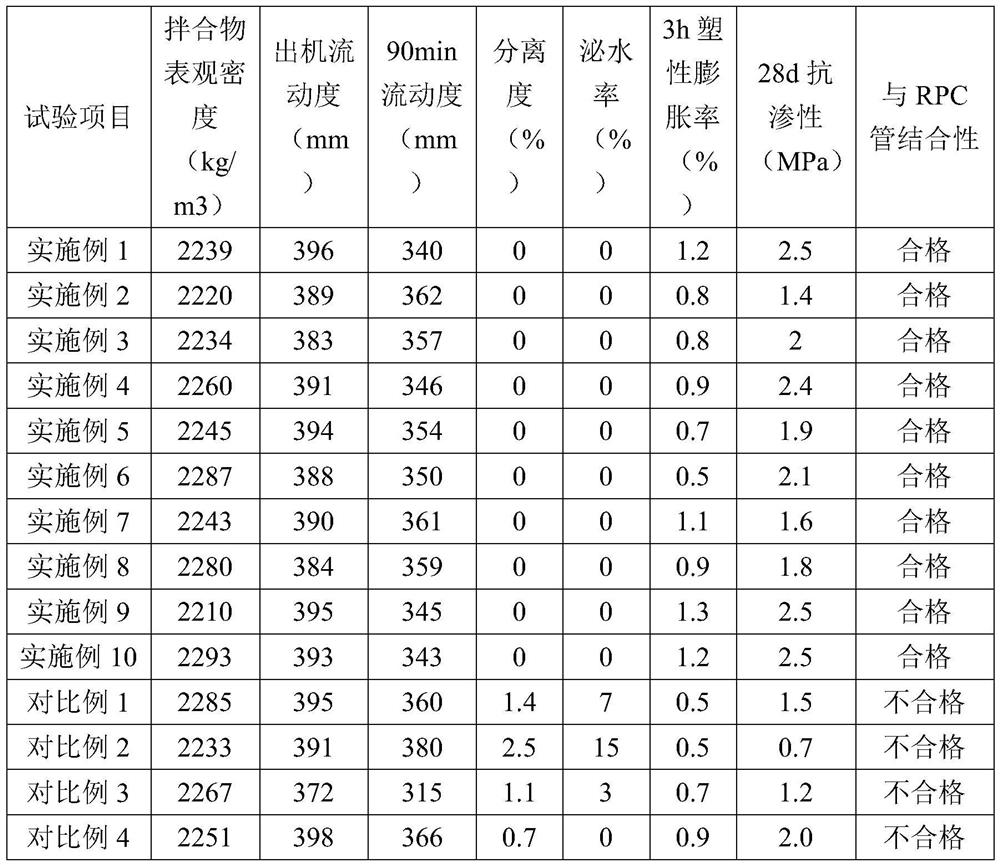

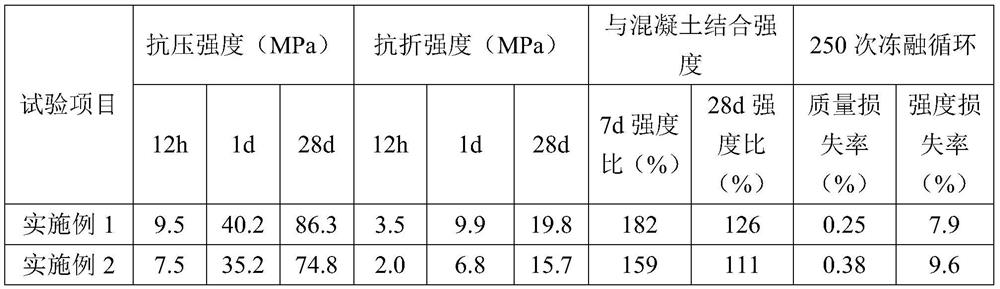

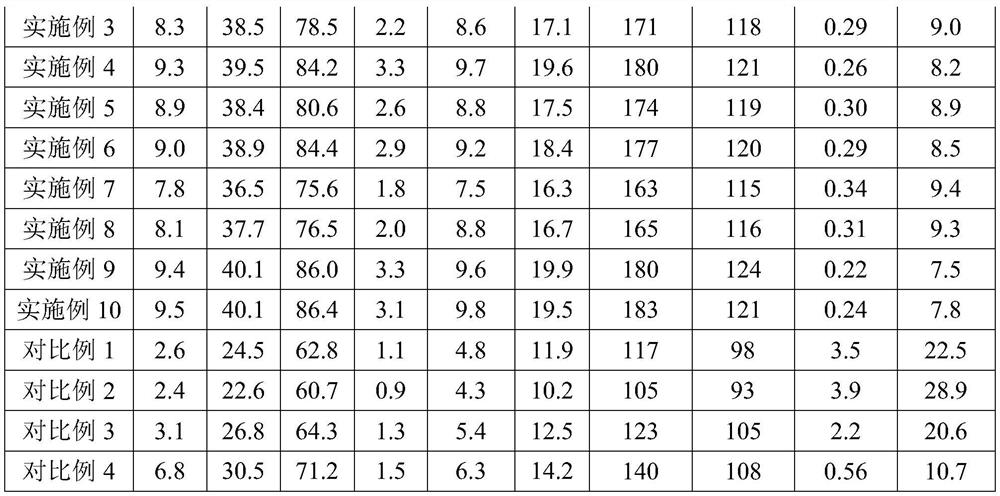

Examples

Embodiment 1

[0046] This example is made of the following raw materials in mass percentage: 55.42% cement, 38% graded aggregate, 2.0% viscosity modifier, 4% expansion agent, 0.30% early strength agent, 0.25% water reducing agent, water retaining agent 0.02%, defoamer 0.01%; the cement is composed of 91% of ordinary Portland cement with a cement strength grade of 52.5 and 9% of sulphoaluminate cement with a cement strength grade of 42.5 by mass percentage; The graded aggregate is composed of the following quartz sand by mass percentage: 82% of 70-100 mesh quartz sand, 18% of 100-200 mesh quartz sand; Base cellulose ether and Brunei gum; the expansion agent is compounded by 1% ammonium azodicarboxylate and 99% magnesium oxide in mass percentage; the viscosity modifier is fly ash extract, and its accumulation Density≥700kg / m 3 , silica content ≥ 50%, aluminum oxide content ≥ 20%; the water reducer is a polycarboxylate water reducer, and the water reducing rate of the mortar is ≥ 25%; the def...

Embodiment 2

[0056] A micro-expansion grouting material for tunnel lining vault grouting with mold in this embodiment has 54.0% cement, 40% graded aggregate, 3.0% viscosity modifier, 2.5% expansion agent, 0.21% early strength agent, and 0.26% of water agent, 0.01% of water-retaining agent, and 0.02% of defoamer; the cement is ordinary Portland cement with a strength grade of 52.5; the graded aggregate is composed of the following quartz sand by mass percentage: 70-100 85% of mesh quartz sand, 15% of 100-200 mesh quartz sand; the water-retaining agent is xanthan gum; the expansion agent is composed of 1% p-toluenesulfonyl hydrazide and 99% magnesium oxide according to mass percentage; The viscosity modifier is a fly ash extract with a bulk density ≥ 700kg / m 3 , silica content ≥ 50%, aluminum oxide content ≥ 20%; the water reducer is a polycarboxylate water reducer, and the water reducing rate of the mortar is ≥ 25%; the defoamer is a polyether modified Non-toxic silicone defoamer. Its pre...

Embodiment 3

[0058] A micro-expansion grouting material for tunnel lining vault grouting with mold in this embodiment has 60% cement, 35% graded aggregate, 2.0% viscosity modifier, 2.7% expansion agent, 0.05% early strength agent, and 0.20% of water agent, 0.03% of water retaining agent, and 0.02% of defoamer; the cement is ordinary Portland cement with a strength grade of 52.5; the graded aggregate is composed of the following quartz sand by mass percentage: 70-100 80% of mesh quartz sand, 20% of 100-200 mesh quartz sand; the water-retaining agent is ethyl cellulose ether; the expansion agent is composed of 1% iminodiacetonitrile and 99% magnesium oxide by mass percentage ; The viscosity modifier is a fly ash extract with a bulk density ≥ 700kg / m 3 , silica content ≥ 50%, aluminum oxide content ≥ 20%; the water reducer is a polycarboxylate water reducer, and the water reducing rate of the mortar is ≥ 25%; the defoamer is a polyether modified Non-toxic silicone defoamer. Its preparation ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com