Formula and preparation method of antistatic silicon rubber

A silicone rubber and anti-static technology, applied in the formulation of anti-static silicone rubber and the preparation of anti-static silicone rubber, can solve the problem of poor tensile strength, tear strength and wear resistance, large changes in physical and mechanical properties, and inconsistency. It is suitable for problems such as promotion and use, and achieves the effect of improving tensile strength and tear strength, good electrical conductivity and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

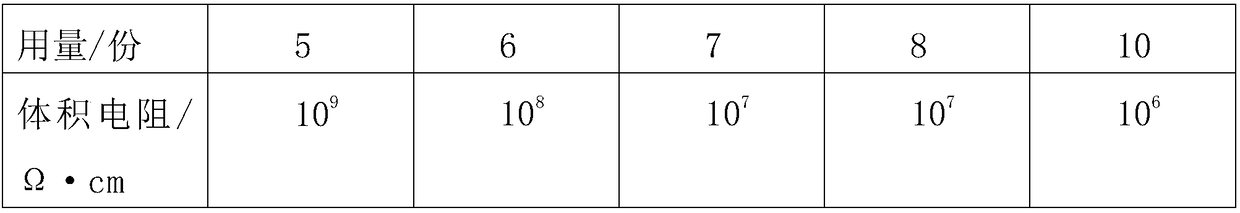

Embodiment 1

[0028] A formula for antistatic silicone rubber, the raw materials of which are as follows in parts by weight: 40 parts of silicone rubber, 5 parts of vinyl silicone rubber, 3 parts of stearic acid, 5 parts of fluorosilicone rubber, 1 part of vulcanizing agent, and reinforcing filler 7 parts, 3 parts of weak reinforcing filler, 3 parts of additive, 3 parts of coloring agent.

[0029] The vulcanizing agent is a mixture of benzoyl peroxide, 2,4-dichlorobenzoyl peroxide, di-tert-butyl peroxide and dicumyl peroxide, and the benzoyl peroxide, 2,4 - The mixing ratio of benzoyl dichloride, di-tert-butyl peroxide and dicumyl peroxide is 8:1:1:1, and the reinforcing filler is acetylene carbon black, conductive furnace black and conductive The mixed material of channel black, the mixing ratio of the acetylene carbon black, conductive furnace black and conductive channel black is 3:1:1, the vinyl content in the vinyl silicone rubber is not less than 1.17mmol / g, the weak supplement The s...

Embodiment 2

[0044] A formula for antistatic silicone rubber, the raw materials of which are as follows in parts by weight: 45 parts of silicone rubber, 6 parts of vinyl silicone rubber, 4 parts of stearic acid, 7.5 parts of fluorosilicone rubber, 2 parts of vulcanizing agent, and reinforcing filler 8.5 parts, 4 parts of weak reinforcing filler, 4 parts of additive, 4 parts of coloring agent.

[0045] The vulcanizing agent is a mixture of benzoyl peroxide, 2,4-dichlorobenzoyl peroxide, di-tert-butyl peroxide and dicumyl peroxide, and the benzoyl peroxide, 2,4 - The mixing ratio of benzoyl dichloride, di-tert-butyl peroxide and dicumyl peroxide is 8:1:1:1, and the reinforcing filler is acetylene carbon black, conductive furnace black and conductive The mixed material of channel black, the mixing ratio of the acetylene carbon black, conductive furnace black and conductive channel black is 3:1:1, the vinyl content in the vinyl silicone rubber is not less than 1.17mmol / g, the weak supplement ...

Embodiment 3

[0060] A formula for antistatic silicone rubber, its raw materials are as follows in parts by weight: 50 parts of silicone rubber, 7 parts of vinyl silicone rubber, 5 parts of stearic acid, 10 parts of fluorosilicone rubber, 3 parts of vulcanizing agent, and reinforcing filler 10 parts, 5 parts of weak reinforcing filler, 5 parts of additive, 5 parts of coloring agent.

[0061] The vulcanizing agent is a mixture of benzoyl peroxide, 2,4-dichlorobenzoyl peroxide, di-tert-butyl peroxide and dicumyl peroxide, and the benzoyl peroxide, 2,4 - The mixing ratio of benzoyl dichloride, di-tert-butyl peroxide and dicumyl peroxide is 8:1:1:1, and the reinforcing filler is acetylene carbon black, conductive furnace black and conductive The mixed material of channel black, the mixing ratio of the acetylene carbon black, conductive furnace black and conductive channel black is 3:1:1, the vinyl content in the vinyl silicone rubber is not less than 1.17mmol / g, the weak supplement The strong ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap