PFM-based lithium niobate nano-domain processing and imaging method

An imaging method, lithium niobate technology, applied in nanotechnology, chemical instruments and methods, crystal growth, etc., can solve problems such as difficult to obtain nanodomain structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] One, the present invention will be further described below in conjunction with embodiment.

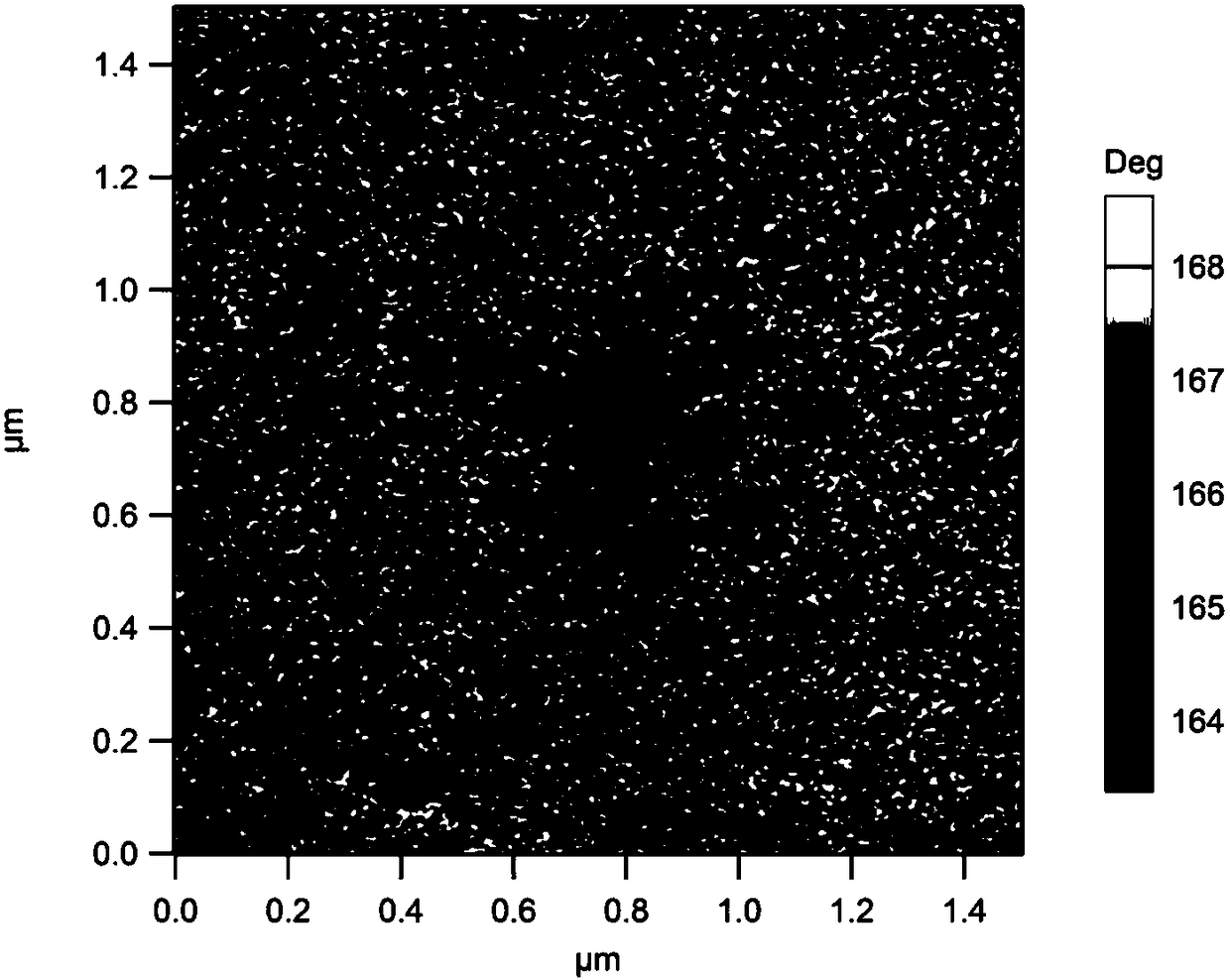

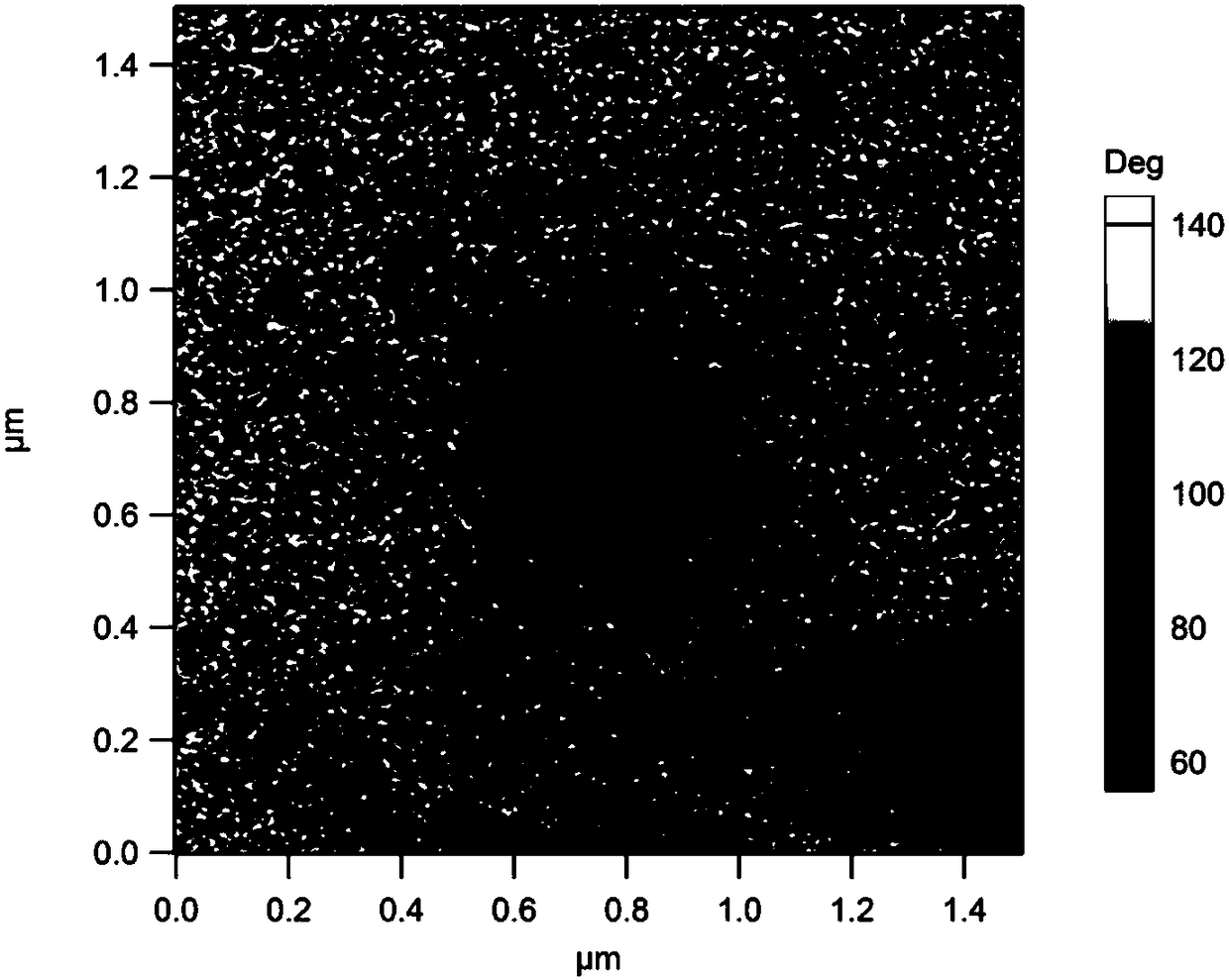

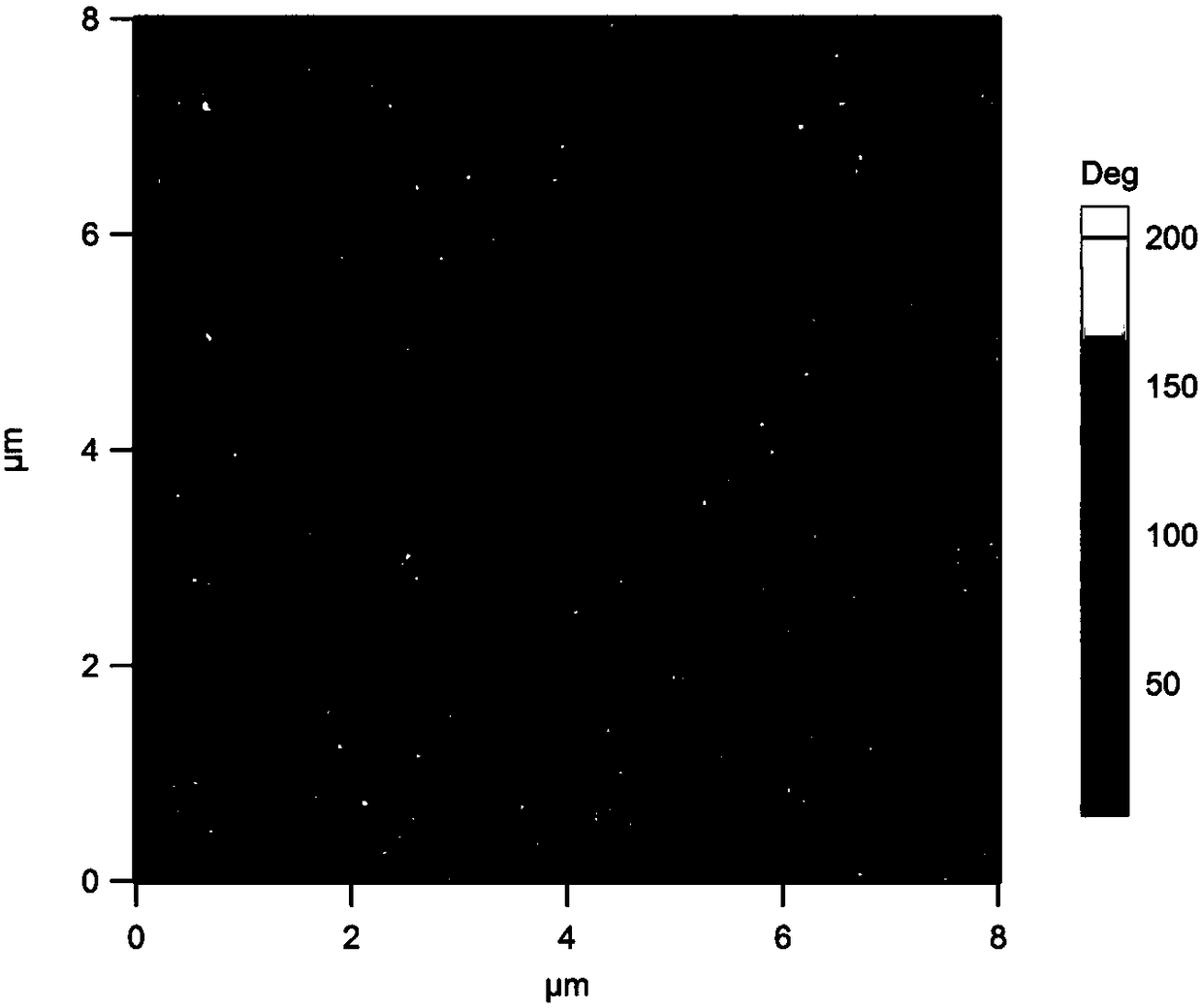

[0018] A kind of lithium niobate nano-domain processing and imaging method based on PFM is carried out according to the following steps:

[0019] Step 1, scanning the surface of the lithium niobate thin film with a conductive probe applying a first AC voltage, the voltage value of the first AC voltage is less than the inversion voltage value of the iron domain of lithium niobate;

[0020] The lithium niobate film is a lithium niobate single crystal film polarized unidirectionally along the c-axis crystal axis;

[0021] In order to ensure the removal effect of the surface charge of the film, a conductive probe can be used for multiple scans;

[0022] Step 2, using a conductive probe that applies a first DC voltage to perform nano-domain processing on the scanned lithium niobate film, and the voltage value of the first DC voltage is greater than or equal to the reversal voltage v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com