A construction method for assembled piers with mixed reinforcement of ordinary steel bars and precision-rolled threaded steel bars

A technology of fine-rolled threads and ordinary steel bars, applied in the erection/assembly of bridges, buildings, bridge construction, etc., can solve the problem of difficulty in simultaneously reducing the maximum displacement response of piers during earthquakes and residual displacement after earthquakes, and improve the post-earthquake function. performance and repairability, ensure high pier efficiency, and improve the effect of pier stiffness after yielding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

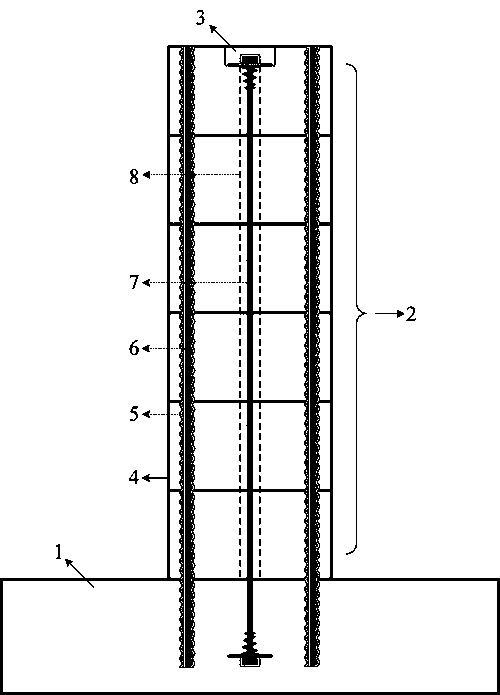

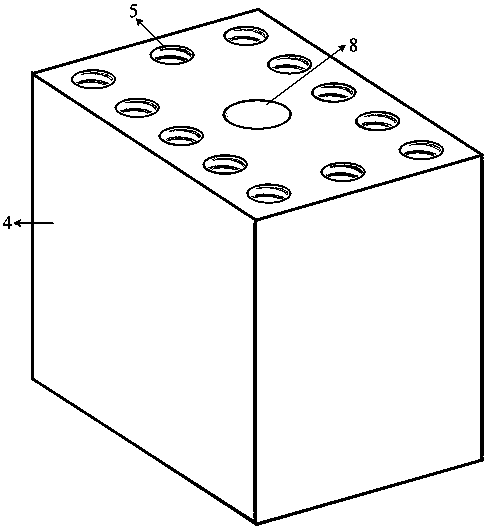

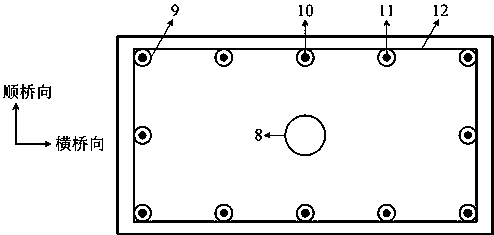

[0032] Example 1, the construction method of the assembled pier with mixed reinforcement of ordinary steel bars and fine-rolled threaded steel bars is as follows: Figure 4 Shown: First, pour the foundation of the pier cap, reserve corrugated channels during pouring, so that the penetrating longitudinal reinforcement can be inserted into the foundation for anchoring; then, assemble the bottom section of the pier, and assemble the remaining sections in turn, so that the prestressed tendons are separated from the The prestressed tendon passes through the tunnel 8; after the assembly is completed, the prestressed tendon is stretched; finally, the penetrating longitudinal tendons are placed in the reserved corrugated tunnel 5, and pressure grouting is performed on the tunnel to ensure that the grouting is full and dense. The penetrating longitudinal reinforcement is constrained by the surrounding grouting material, the metal bellows 9 and the stirrup 12, so it is not prone to compres...

Embodiment 2

[0033] Example 2, such as Figure 5 As shown, the difference between this embodiment and the foregoing embodiment 1 is that the pier body of the assembled pier with mixed reinforcement of ordinary steel bars and fine-rolled threaded steel bars has only one prefabricated section 4. When the pier slenderness ratio is not greater than 6, the entire pier can be prefabricated as a whole section, which can improve the efficiency of pier assembly. Moreover, since the pier slenderness ratio is not greater than 6, the size and weight of the entire section will not be too large and difficult to transport and assemble. When adopting the same or similar design and construction plan as in Example 2, it should be noted that the size and weight of the prefabricated pier section meets the relevant transportation regulations and does not exceed the tonnage limit of the hoisting equipment.

Embodiment 3

[0034] Example 3, such as Image 6 As shown, the difference between this embodiment and the foregoing embodiment 1 is that ordinary steel bars and finished-rolled rebars only penetrate through the lower sections of the assembled pier 2 and are not arranged along the entire pier. For cantilever piers, the bending moment at the bottom of the pier is the largest under the action of an earthquake, and the bending moment gradually decreases from the bottom of the pier upward. According to the pier bending moment distribution during seismic design, the longitudinal steel reinforcement ratio can be gradually reduced and finally cut off at a reasonable height. The determination of the truncation position of the longitudinal reinforcement shall comply with the corresponding seismic design code. When the height of the assembled pier with mixed reinforcement of ordinary steel bars and fine-rolled steel bars is relatively large, this scheme can effectively reduce the amount of steel used ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com