Separated type tunnel arch-replacement supporting structure and construction method thereof

A support structure and separate technology, applied in the field of support structures of separate tunnels, can solve the problems of time-consuming and laborious erection of support structures, unguaranteed construction period, and incompatibility with construction requirements, etc., so as to improve construction quality and enhance The effect of strength and convenience of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with accompanying drawing of description, but protection scope of the present invention is not limited thereto:

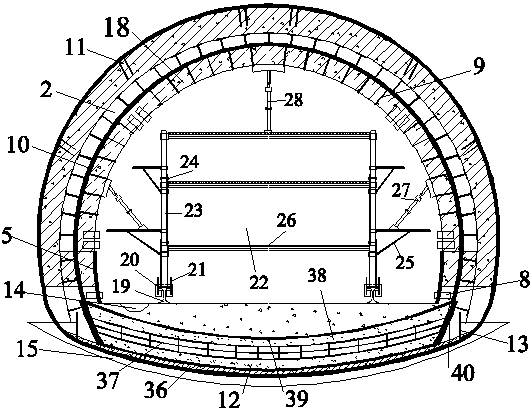

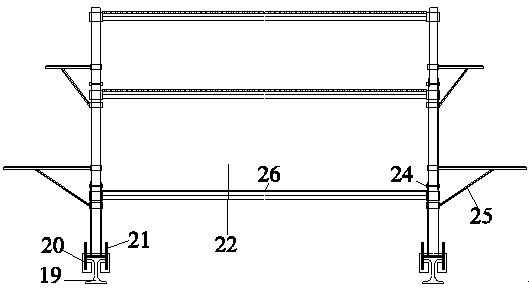

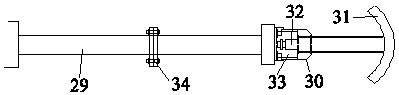

[0032] Such as Figure 1-8 As shown, the separated tunnel arch support structure of the present invention includes a support structure body, and the support structure body is provided with a hollow grouting hole 11, an original steel frame 1, a new steel frame 2, a small grouting Conduit 4, short side wall 5, temporary inverted arch structure, steel mesh 10, hollow grouting hole 11, inverted arch 12 and secondary lining structure 18, the temporary inverted arch structure is composed of I-shaped steel frame 6 and locking foot steel pipe 7, It is erected at the middle height of the tunnel and reinforced by wooden wedges; the hollow grouting hole 11 is reserved behind the primary support structure, and the small grouting conduit 4 is arranged in the circumferential position of the tunnel. Afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com