Solar cell layout adhesive tape pasting device

A technology for solar cells and tapes, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as low degree of automation, and achieve the effects of improving manufacturing efficiency, improving quality and manufacturing efficiency, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

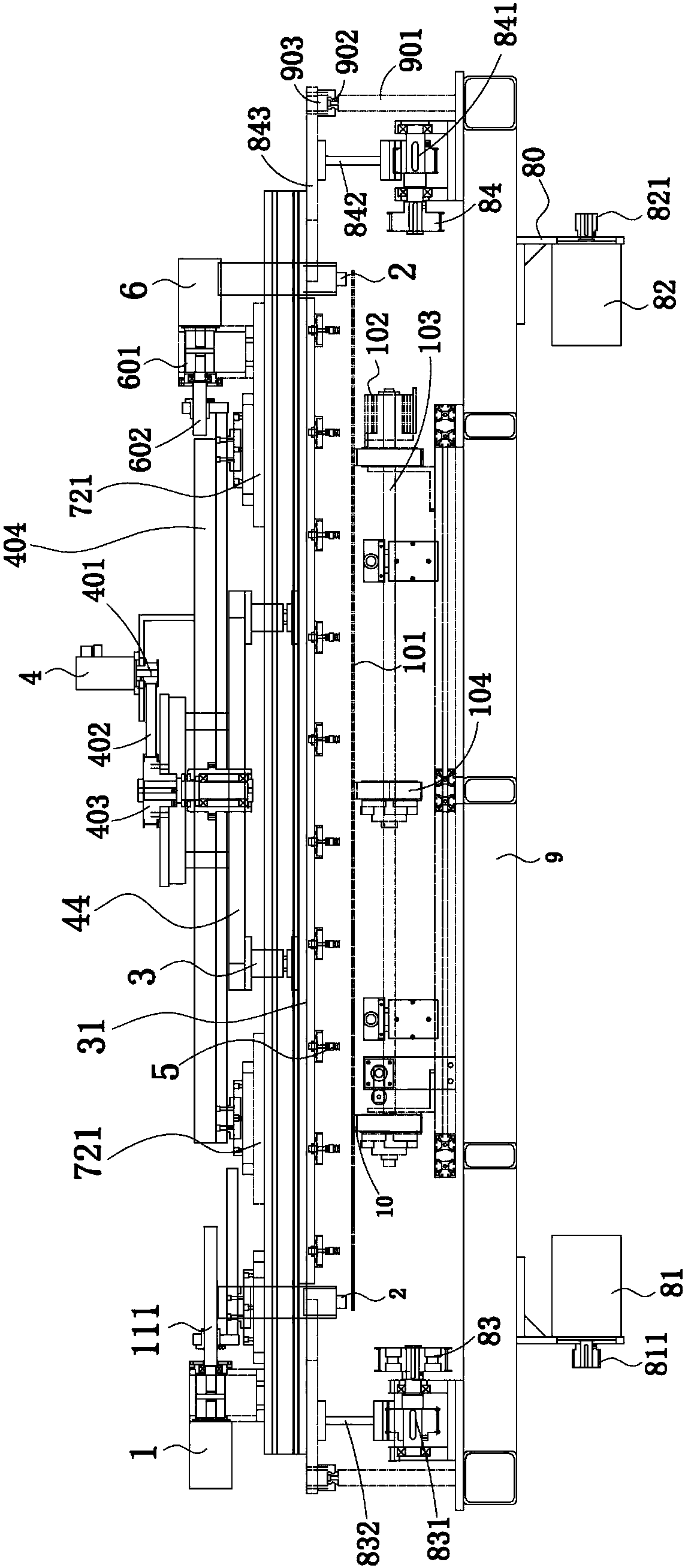

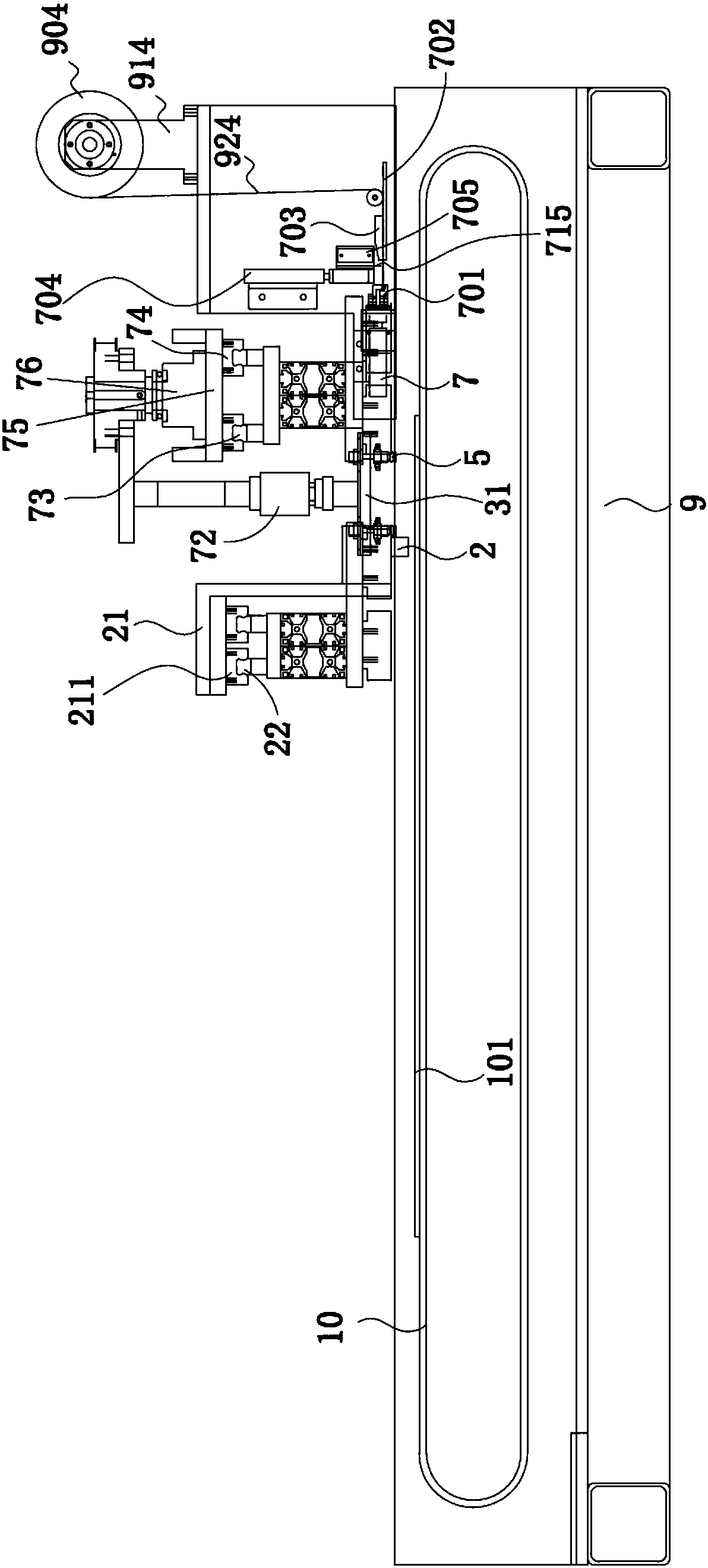

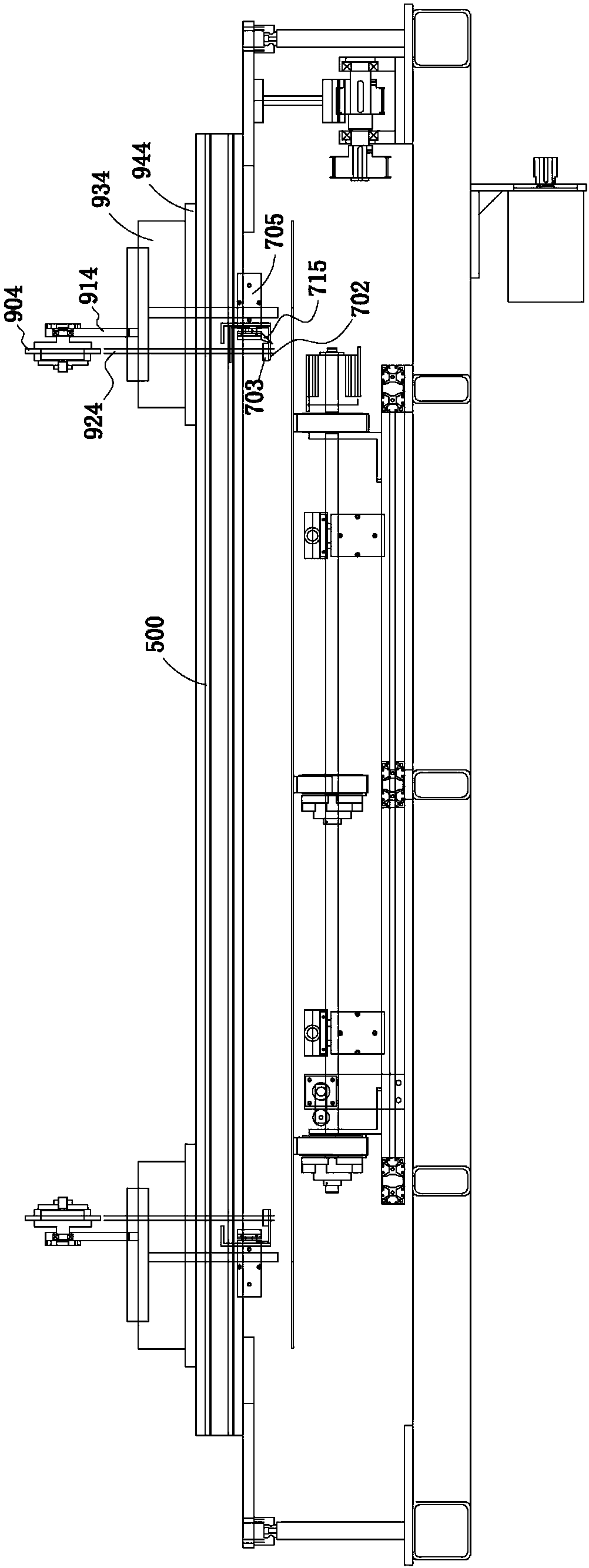

[0036] Please refer to Figure 1 to Figure 5 Shown is a specific embodiment of a solar cell typesetting device of the present invention.

[0037] In the manufacturing process of the photovoltaic module, the battery strings 130 , 130 , etc., which have been automatically welded by the laying machine, must be placed on the substrate glass 101 in advance. Substrate glass 101 along image 3The direction of arrow D in the middle flows forward. When the PV modules in the semi-cost state are transferred from the laying machine to other equipment in other PV module production lines, the position of the already positioned cell strings will be shifted. The so-called position offset may be a left-right offset perpendicular to the arrow D direction, a front-back offset along the arrow D direction, or a rotational offset. Therefore, when the offset positions of multiple battery strings exceed the allowable value, it is necessary to Figure 4 shown) to adjust the position to meet the el...

Embodiment 2

[0053] Compared with the first embodiment, the main difference between this embodiment is that in this embodiment, the optical imaging device 2 is only provided on the bracket 21 provided at one end of the third beam 400 . For the technical features of the same parts of this embodiment and the first embodiment, please refer to the first embodiment, which will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com