Cleaning device for control cabinet

A cleaning device and control cabinet technology, applied in the field of electrical cabinets, can solve the problems of untimely and effective treatment of snow accumulation, easy access of snow water personnel, damage of electrical components, etc., and achieve easy replacement and maintenance, convenient cleaning and safe use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

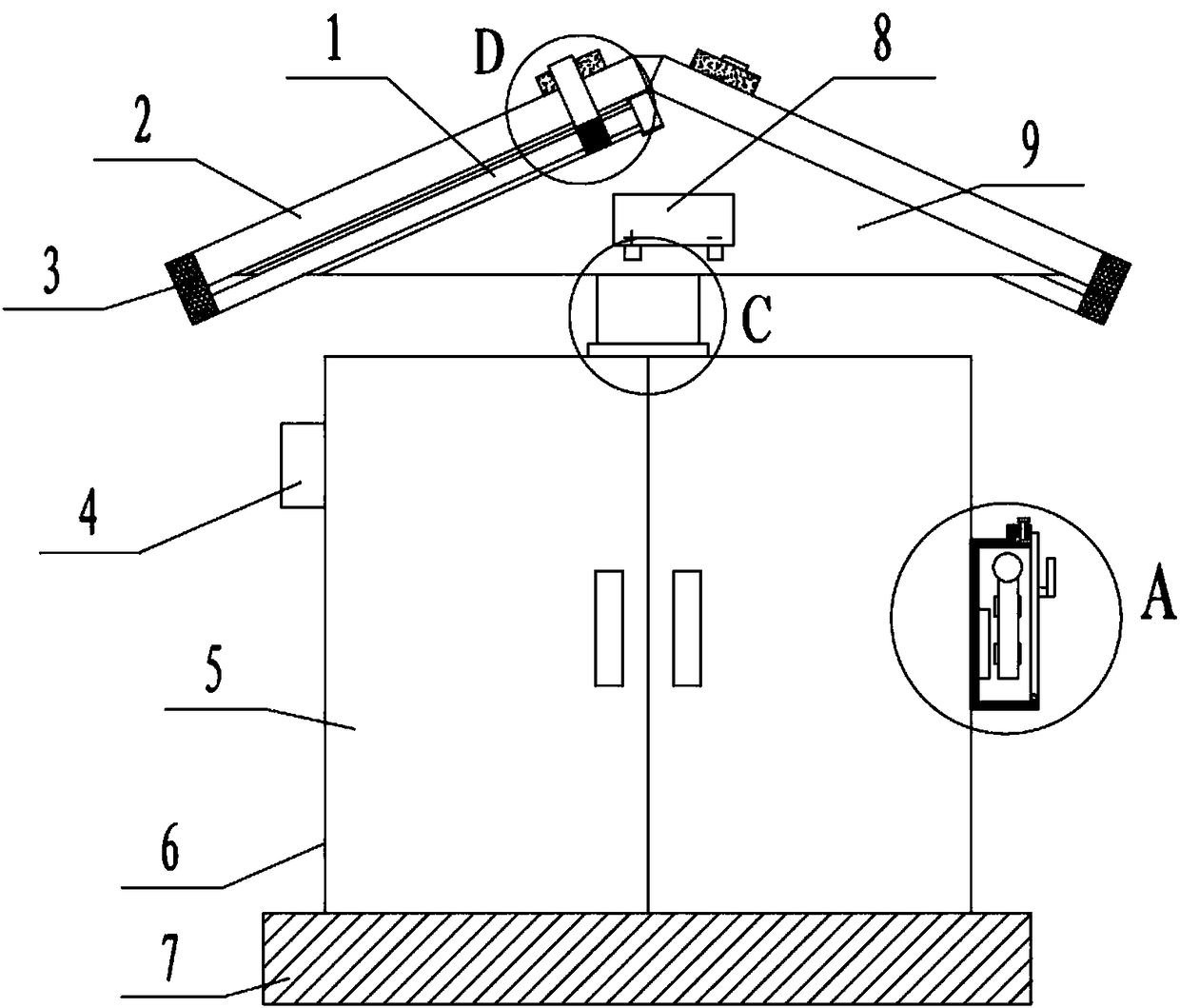

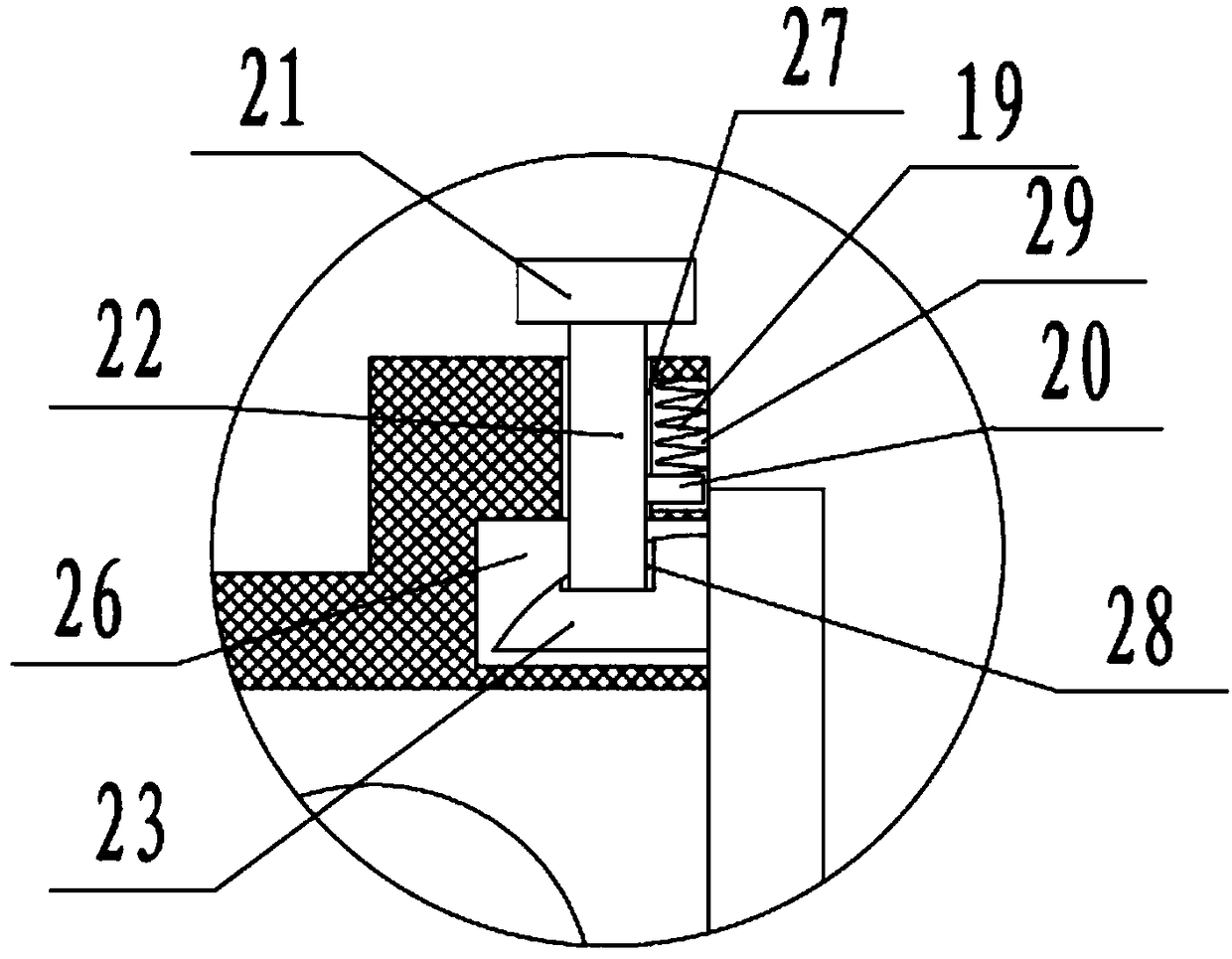

[0025] Embodiment 1: as Figure 1-9 As shown, a cleaning device for a control cabinet includes a cleaning head 10, a connecting rod 11, a slider 12 and a drive motor 13. Both ends of the cleaning head 10 are connected to the front and rear sides of the top cover 9 through linear bearings 30, and the outer side of one end is connected to the front and rear sides of the top cover 9 through a connecting rod 11. Fixedly connected to the slider 12, the slider 12 is equipped with a lead screw nut pair to drive it to move, the screw nut pair is connected with a drive motor 13, and the drive motor 13 is fixedly connected to the side of the top cover 9, the screw nut pair The pair includes a lead screw 1 and a screw nut 31. Both ends of the lead screw 1 are connected to the bearing seat 3, and one end extends out of the bearing seat and is connected to the drive motor 13 through a coupling. The bearing seat 3 is fixedly connected to the top cover 9, and the straight line The two ends o...

Embodiment 2

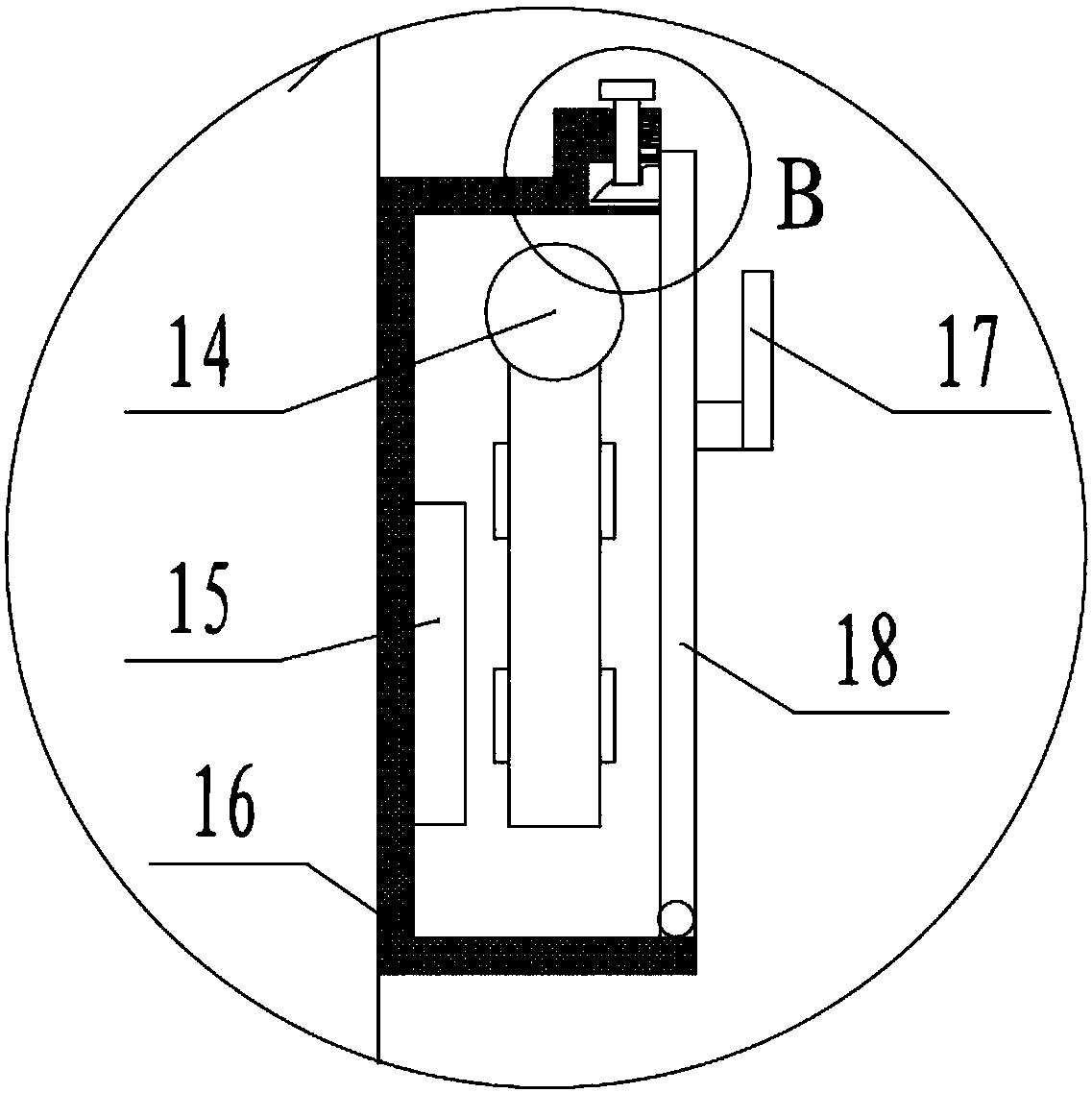

[0030] Embodiment 2: as Figure 1-9 As shown, a control cabinet includes a cabinet body 6, the cabinet body 6 is fixedly connected to the base 7, two movable doors 5 are arranged on the front side of the cabinet body 6, LED lights 4 are arranged on the left side, and the side of the cabinet body 6 An alarm box 16 is provided, and the outer end of the alarm box 16 is provided with a sealed door 18, and a microphone 14 is installed inside, and the microphone 14 is electrically connected to the input end of the controller 15, and the communication end of the controller 15 is connected to a 4G module, and the 4G module is connected to the mobile The terminal is connected, and the outer surface of the cabinet 6 is evenly sprayed with waterproof paint, and the controller adopts AT89C52.

[0031] Preferably, the lower end of the airtight door 18 is hinged on the end edge of the alarm box 16, and the upper end is connected to the alarm box 16 through a clamping device.

[0032] Prefe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com