IGBT driving circuit of motor controller, and motor controller

A motor controller and drive circuit technology, which is applied in the direction of motor control, amplifier protection circuit layout, DC motor deceleration device, etc., to achieve the effects of rapid action, shortened protection time, and timely protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

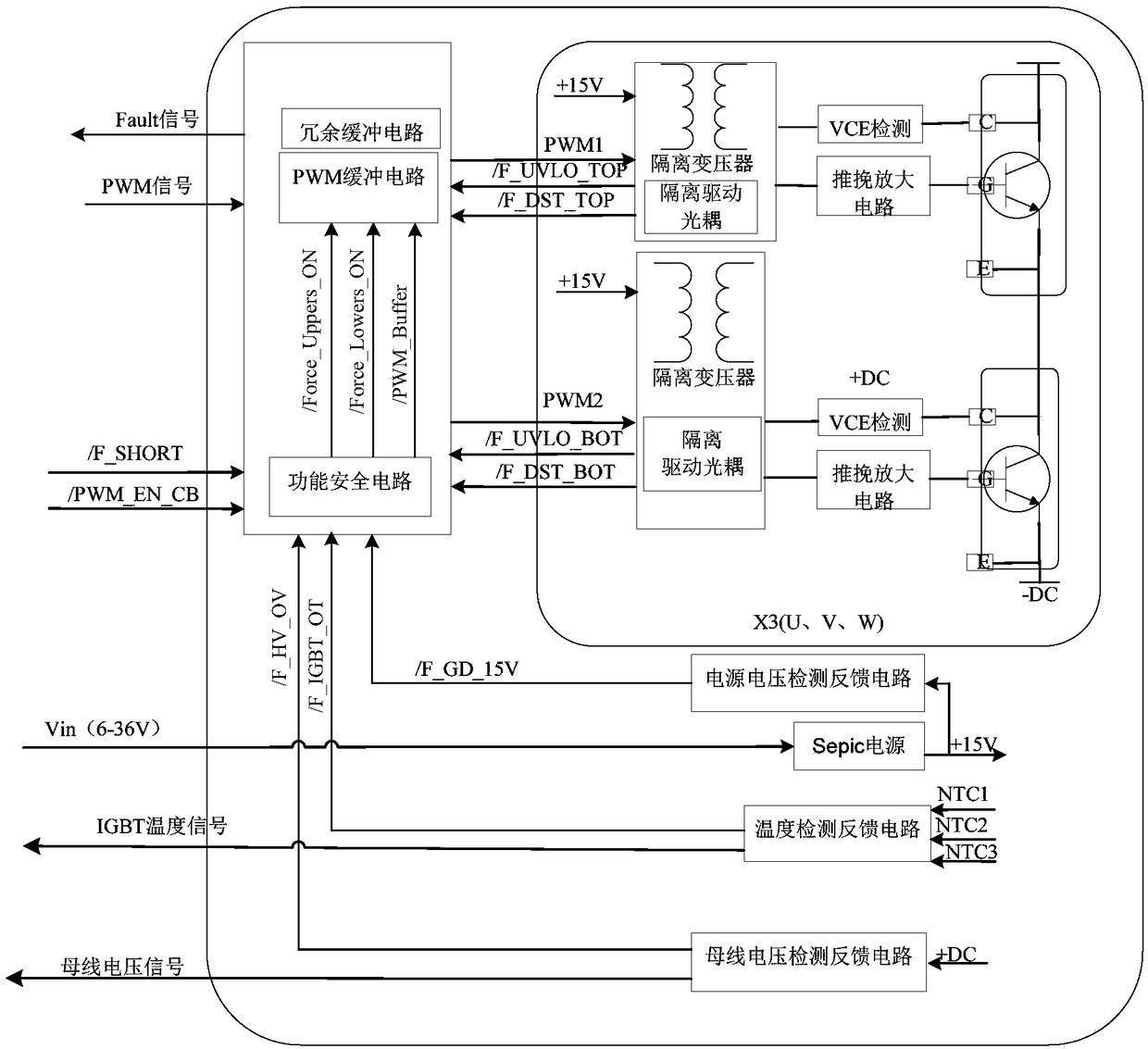

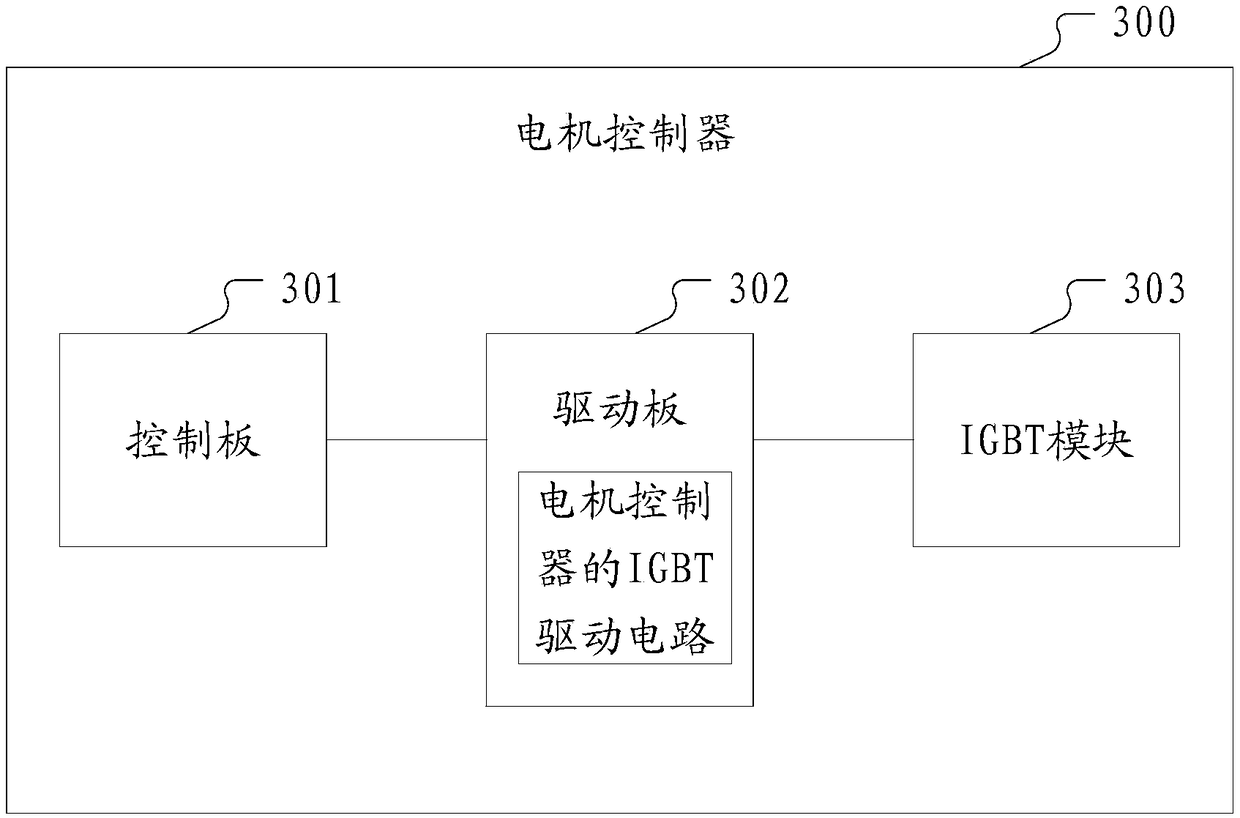

[0032] As the core component of the vehicle's power, the motor controller is composed of many parts, among which the drive circuit is the key part, and it is also the focus of the functional safety design of the vehicle drive motor system. The embodiment of the present application provides an IGBT driving circuit of a motor controller, so as to quickly ensure the safety of the IGBT module and the motor controller when a failure of the IGBT module is detected.

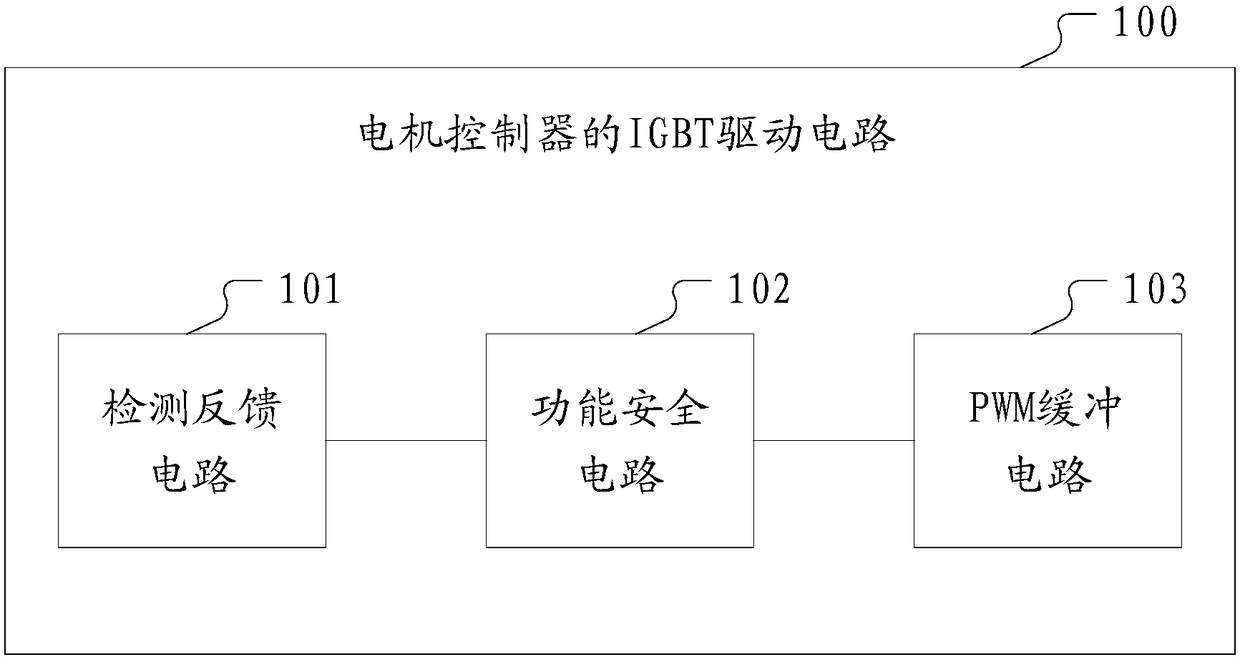

[0033] figure 1 It is a block diagram of the IGBT drive circuit of the motor controller of an embodiment of the present invention, see figure 1 , The IGBT driving circuit of the motor controller of the embodiment of the present invention includes: a functional safety circuit 102 arranged on the motor controller driving board, and a detection feedback circuit 101 and a pulse width modulation PWM buffer respectively connected to the functional safety circuit 102 circuit 103;

[0034] The detection feedback circuit 101 d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com