Multifunctional electric rotary mop

An electric rotating, multi-functional technology, applied in the field of cleaning tools, can solve the problems of reducing the number of replacement cleaning heads, poor cleaning effect on stubborn stains, and increasing the scope of suction, so as to reduce the number of replacement cleaning heads, The effect of reducing secondary pollution of indoor air and increasing the scope of suction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

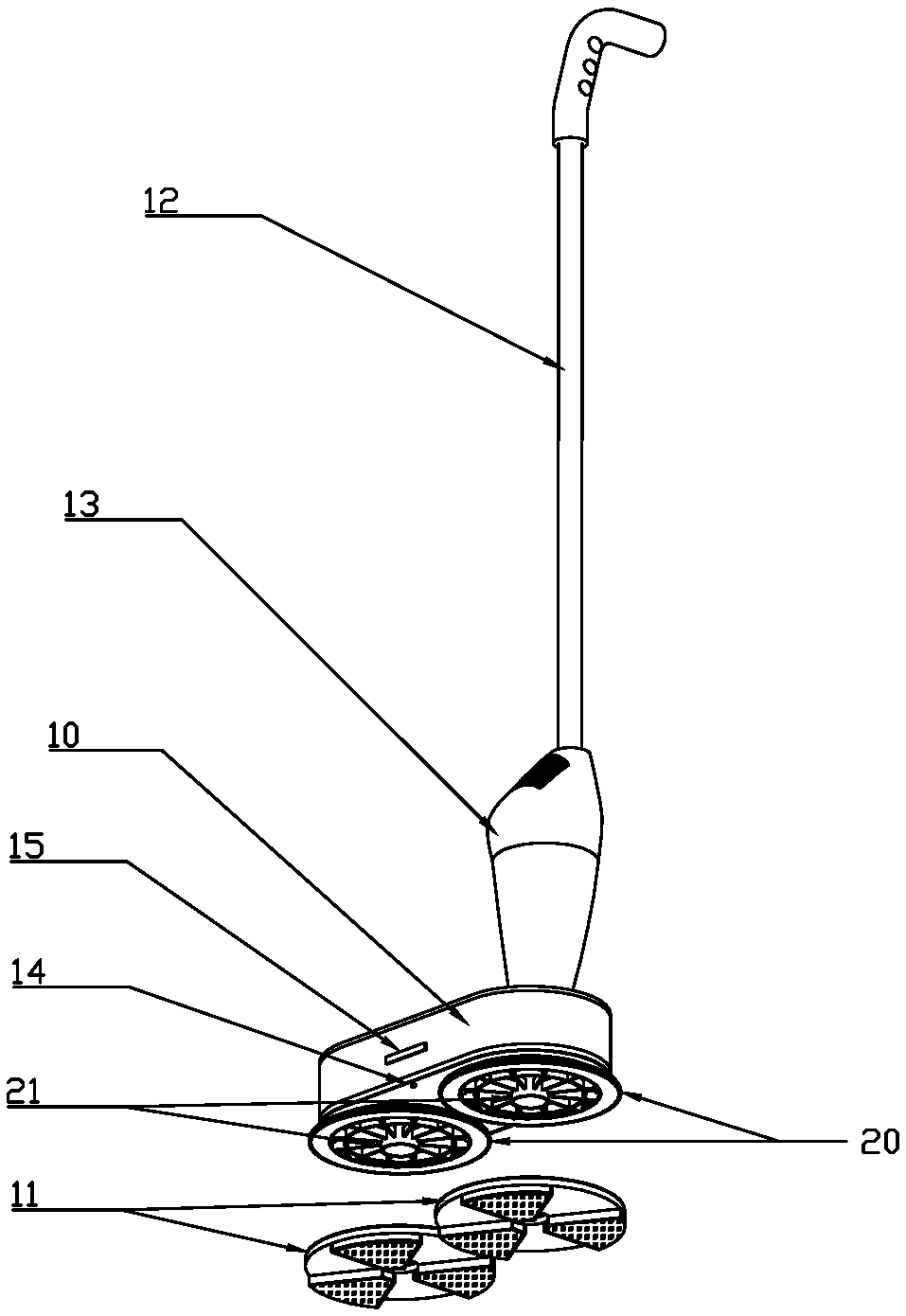

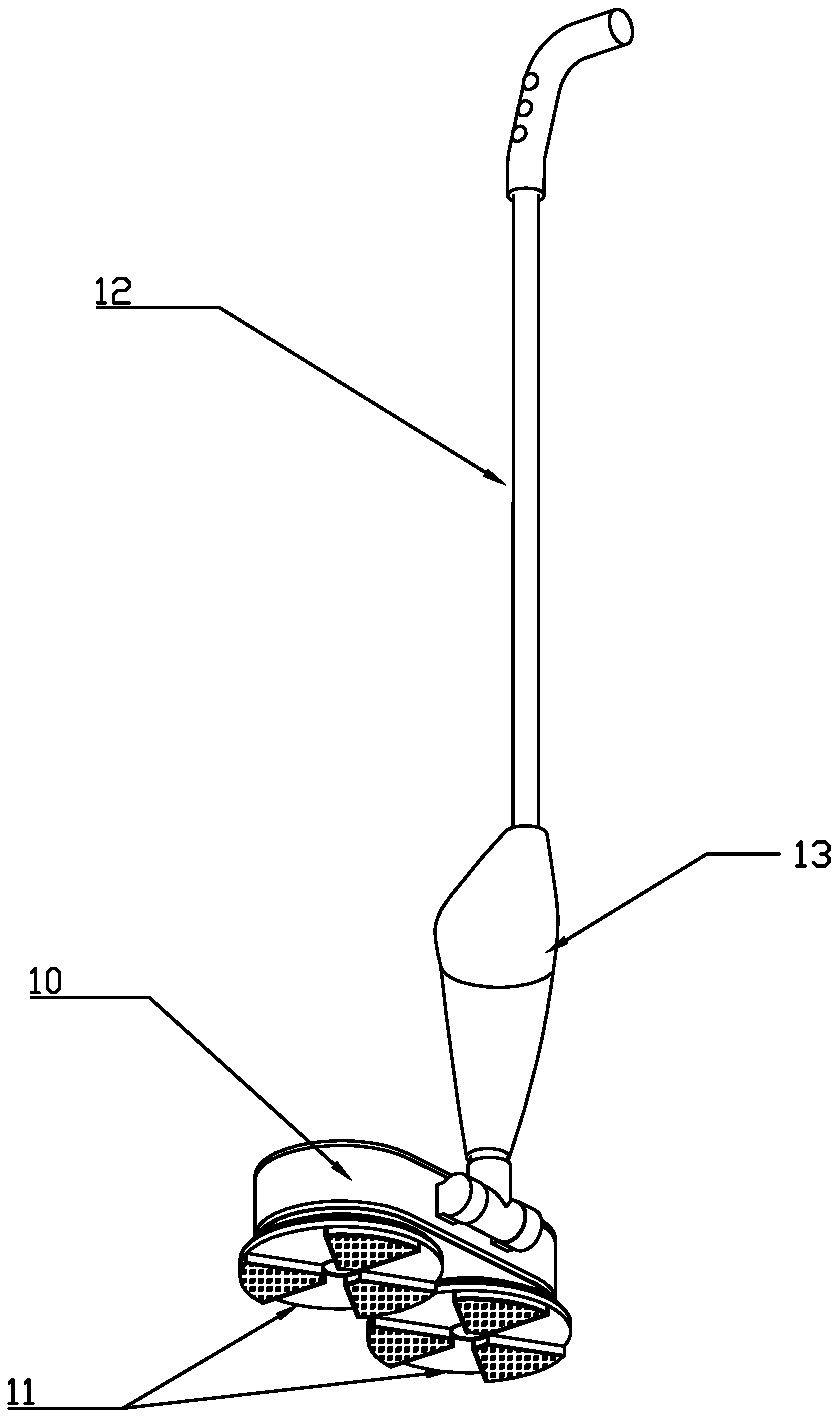

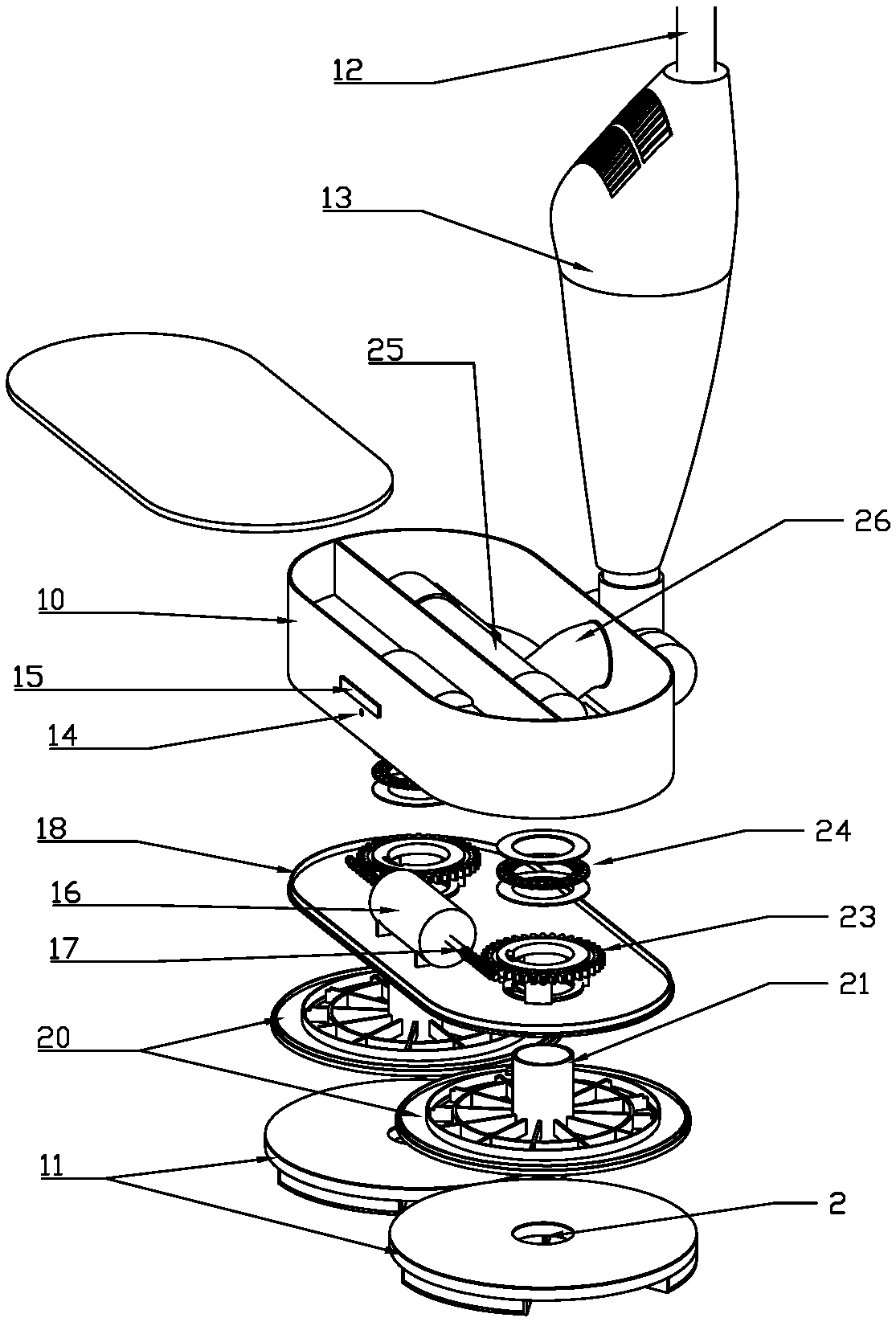

[0023] The technical solutions of the present invention will be described below in conjunction with the accompanying drawings and embodiments.

[0024] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, a preferred embodiment of the present invention comprises a host 10, a mop bar 12 rotatably connected to the host 10, a dust suction device 13 arranged on the mop bar 12, and the mop bar 12 connects with the main machine through the lower end of the dust suction device 13. 10 is hinged, and the air inlet pipe 26 connected to the lower end of the dust suction device 13 enters the interior of the host 10 and communicates with the middle part of the tee pipe 25. Two mounting plates 20 with opposite rotation directions are arranged below the host, and the center position of the mounting plate 20 is A hollow central shaft 21 is provided. The upper end of the central shaft 21 passes through the bottom shell 18 and enters the interior of the main engine 10. The two ends ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com