An environmentally friendly ceramic agent

A kind of pottery and environmental protection technology, applied in the direction of metal material coating process, etc., can solve the problems of low waste water recycling rate, poor corrosion resistance of workpieces, long phosphating treatment time, etc., to achieve fast treatment speed, convenient operation, The effect of improving the adhesion function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

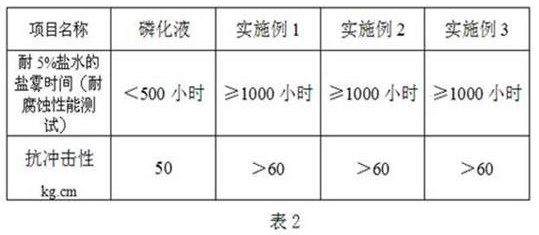

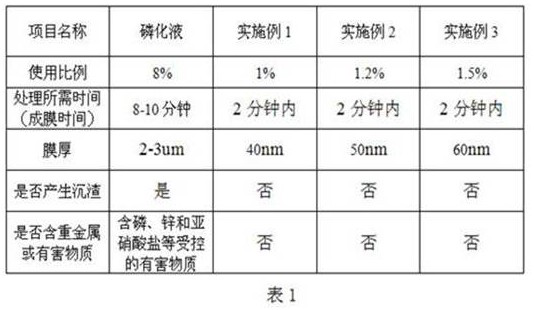

Embodiment 1

[0019] A kind of environment-friendly vitrifying agent, it is made of the component of following weight ratio:

[0020] Titanium zirconium compound 23%,

[0021] Fluoride 3%,

[0022] Organic acids 3%,

[0023] Surfactant 4%,

[0024] Special additives 3%,

[0025] Water 64%.

[0026] In a preferred embodiment, the titanium-zirconium compound is a mixture of 8% by weight zirconium carbonate, 8% by weight fluorozirconic acid and 7% by weight fluorotitanic acid.

[0027] In a preferred embodiment, the fluoride is fluosilicic acid.

[0028] In a preferred embodiment, the organic acid is a mixture of 1.5% tartaric acid and 1.5% citric acid by weight.

[0029] In a preferred embodiment, the surfactant is 2% sodium linear alkylbenzene sulfonate by weight ratio, 1% fatty alcohol polyoxyethylene ether sodium sulfate by weight ratio and 1% by weight ratio Mixture of fatty alcohol polyoxyethylene ether ammonium sulfate.

[0030] In a preferred embodiment, the special additive is...

Embodiment 2

[0032] A kind of environment-friendly vitrifying agent, it is made of the component of following weight ratio:

[0033] Titanium zirconium compound 20%,

[0034] Fluoride 4%,

[0035] Organic acids 4%,

[0036] Surfactant 3%,

[0037] Special additives 3%,

[0038] Water 66%.

[0039] In a preferred embodiment, the titanium-zirconium compound is zirconium carbonate with a weight ratio of 5%, fluozirconic acid with a weight ratio of 5%, potassium fluozirconate with a weight ratio of 5%, and potassium fluozirconate with a weight ratio of 5%. Mixture of sodium fluozirconate.

[0040] In a preferred embodiment, the fluoride is 1% by weight of hydrofluoric acid, 1% by weight of sodium fluoride, 1% by weight of ammonium bifluoride and 1% by weight of silicon fluoride Mixture of acids.

[0041] In a preferred embodiment, the organic acid is 1% by weight of carboxylic acid, 1% by weight of sulfonic acid, 1% by weight of sulfinic acid and 1% by weight of sulfuric acid the mix. ...

Embodiment 3

[0045] A kind of environment-friendly vitrifying agent, it is made of the component of following weight ratio:

[0046] Titanium zirconium compound 18%,

[0047] Fluoride 5%,

[0048] Organic acid 5%,

[0049] Surfactant 5%,

[0050] Special additives 5%,

[0051] Water 62%.

[0052] In a preferred embodiment, the titanium-zirconium compound is 6% by weight of zirconium carbonate, 4% by weight of fluorozirconic acid, 2% by weight of potassium fluorotitanate, and 2% by weight of A mixture of sodium fluorotitanate and 4% fluorotitanic acid by weight.

[0053] In a preferred embodiment, the fluoride is a mixture of potassium fluoride at a weight ratio of 1%, potassium hydrofluorate at a weight ratio of 1%, and fluosilicic acid at a weight ratio of 3%.

[0054] In a preferred embodiment, the organic acid is a mixture of 1% amino acid by weight, 2% tartaric acid by weight and 2% citric acid by weight.

[0055] In a preferred embodiment, the surfactant is 1% fatty alcohol pol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com