Template supporting system of cast-in-place concrete beam and slab structure

A technology for supporting concrete beams and formwork, which is applied in the fields of formwork/formwork/work frame, building structure, and on-site preparation of building components. Flexible, easy to control the position and verticality of the pole, and ensure the effect of construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

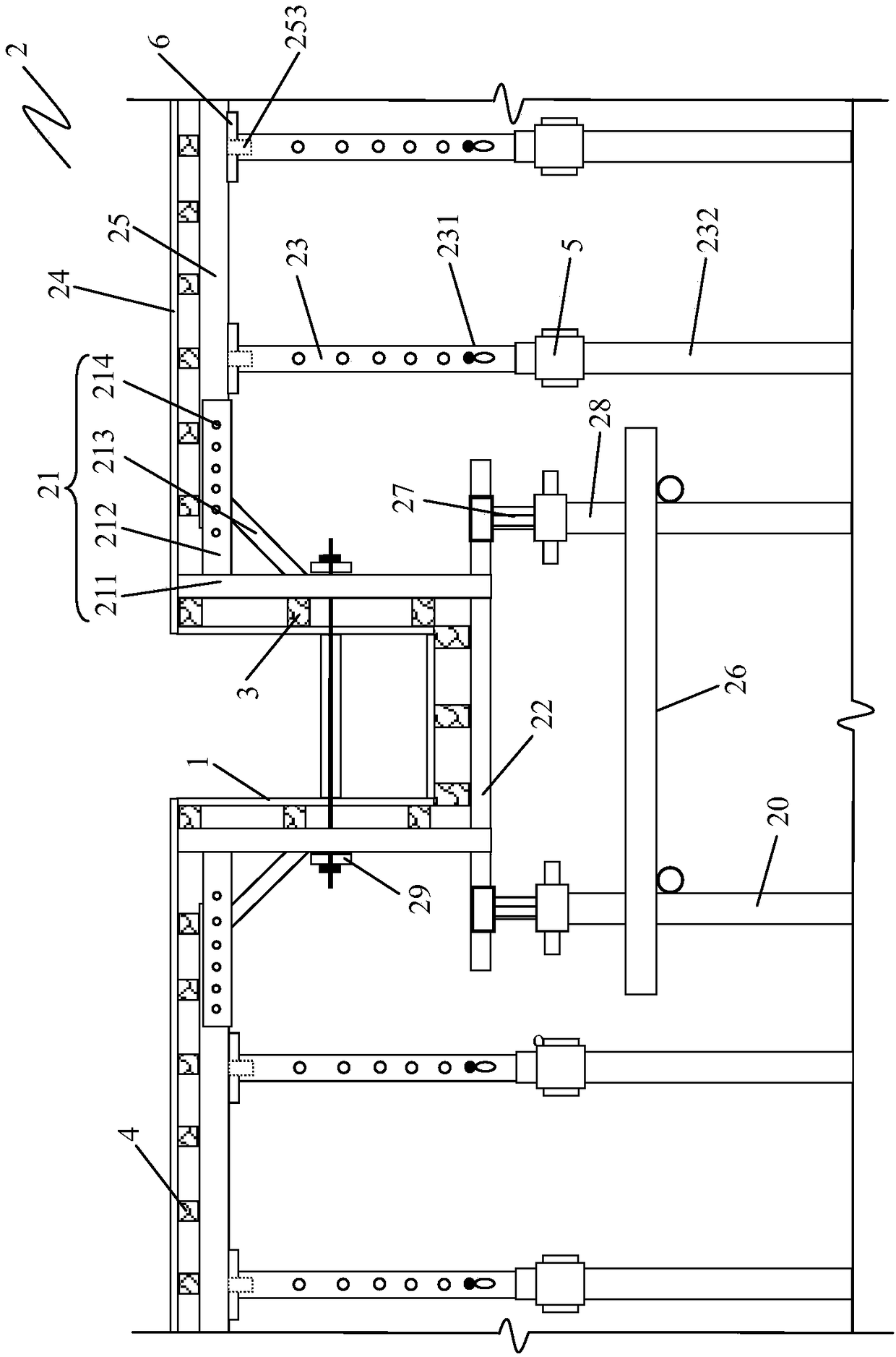

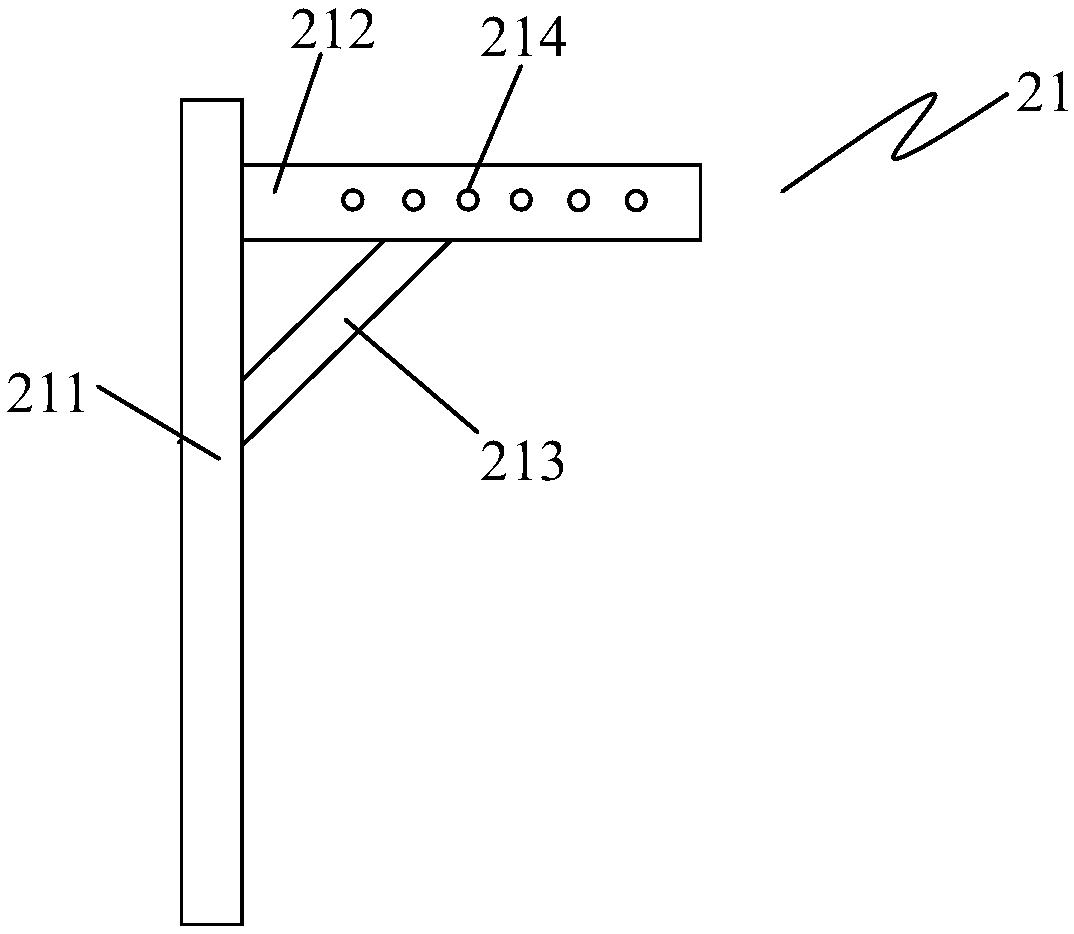

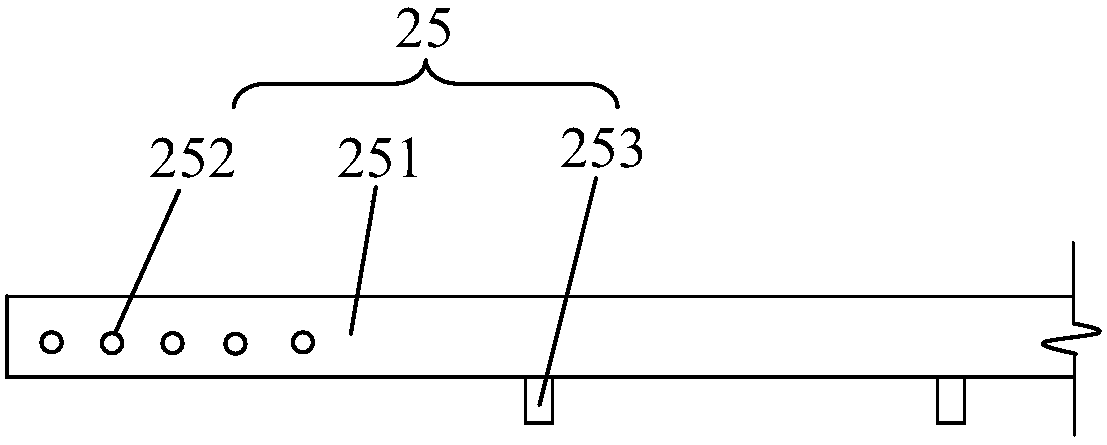

[0023] see figure 1 with figure 2 As shown, a cast-in-place concrete beam-slab structure formwork support system includes a beam formwork mechanism 1 and a plurality of support units 2, and each support unit 2 includes two side formwork connectors 21, a joist 22, a plurality of Telescopic support 23, two-plate formwork 24, two main grids 25, one horizontal bar 26, two jacking brackets 27, two vertical bars 28 and two beam supports 20; on both sides, and realize the fastening connection with the beam formwork mechanism 1 through the pull bolts 29; Between the beam formwork mechanism 1 and between the two-side formwork connectors 21 and the beam formwork mechanism 1, a plurality of corrugations 3 are arranged respectively; The horizontal bar 26 is arranged below the joist 22 in parallel, and the two vertical bars 28 are fixedly connected to both sides of the horizontal bar 26 respectively; The lower end of the jacking 27 is inserted into the vertical bar 28, and is firmly co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com