Fin type heat exchanger system having cleaning function and method

A finned heat exchanger, cleaning technology, applied in the direction of cleaning heat transfer devices, lighting and heating equipment, flushing, etc., can solve the problems of affecting heat exchange efficiency, dirty blockage, difficult cleaning, etc., and achieve high cleaning efficiency and low energy consumption Low, thorough cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

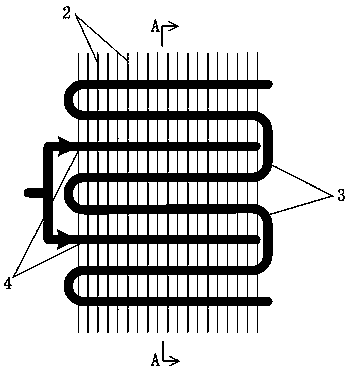

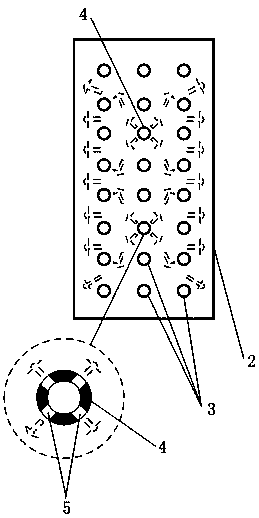

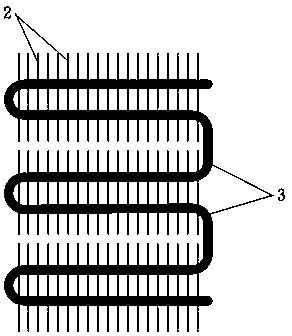

[0031] Usually, when the finned heat exchanger 1 is manufactured, the heat exchange tubes 3 are arranged uniformly and connected and fixed to the fins 2 . When adopting the technical solution of the present invention, in the process of assembling the fins 2 and the heat exchange tubes 3, several vacancies are reserved when the heat exchange tubes 3 are arranged (such as figure 2 shown), and then set the auxiliary pipe 4 in these vacancies (such as figure 1 shown). Through such a design, the auxiliary pipe 4 can be added to the finned heat exchanger 1 without increasing the difficulty of manufacturing the heat exchanger, and integrated with the original structure, passing through the hole 5 on the auxiliary pipe 4 Cleans from the inside out.

[0032] The structure of the hole 5 on the auxiliary pipe 4 is divided into two types:

[0033] Firstly, each hole 5 corresponds to a section of air flow channel formed by adjacent fins 2, so that the auxiliary medium acts on each fin ...

Embodiment 2

[0038] In this embodiment, the cleaning medium conveying device 8 is a piston cylinder, which at least includes a piston 8a, a piston cylinder 8b, and a piston motion control device 8c;

[0039] First, the cleaning medium input interface 7 is opened, the cleaning medium output interface 9 is closed, and the piston 8a is controlled by the piston motion control device 8c to move in reverse to suck the cleaning medium into the piston cylinder 8b; then the cleaning medium input interface 7 is closed, and the cleaning medium output interface 9 Open, the piston 8a is controlled by the piston motion control device 8c to move forward to push the cleaning medium into the auxiliary pipe 4, and then output through the hole 5; then, reciprocate according to this process;

[0040] Wherein, the movement speed of the piston 8a is adjusted by the piston motion control device 8c so as to realize the adjustment of the delivery speed of the cleaning medium; the movement distance of the piston 8a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com