Inserting core butt joint device of connector

A docking device and connector technology, applied in the direction of instrument, optical waveguide coupling, light guide, etc., can solve the problems of difficult to fix the position of the optical fiber ribbon, low production efficiency, high production cost, etc., and achieve compact and stable design, convenient movement, and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to allow those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described below in conjunction with the accompanying drawings.

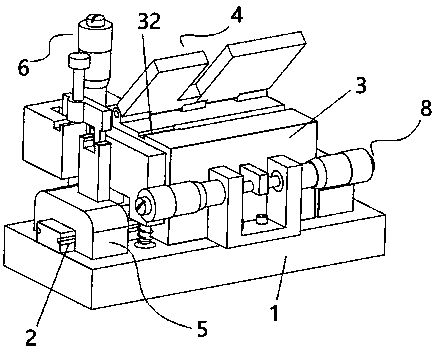

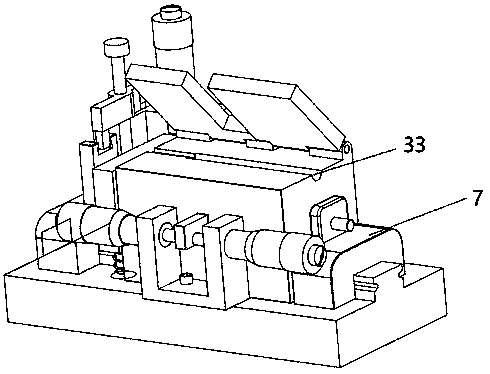

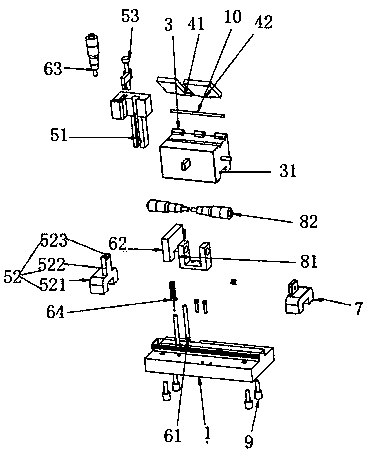

[0020] Specific examples, such as Figure 1~4 As shown, a ferrule docking device for a connector includes a base 1, a slide rail 2 is provided on the base, a slide block 3 for placing optical fibers is provided on the slide rail, and a slide rail running on the bottom surface of the slide block 3 is provided. chute 31, the slider is stuck on the slide rail through the chute, the upper surface of the slider is provided with a groove for placing the optical fiber, one side of the upper surface of the slider is hinged with a fixed module 4, and the front end of the slider is provided with There is a fiber pressing assembly 5 for controlling the flattening of the fiber head and an up and down fine-tuning assembly 6 for fine-tuning the flattening of the fiber he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com