Agricultural mechanical tent

A technology for agricultural machinery and tents, which is applied in application, multi-fluid ratio control, poultry cages or houses, etc., can solve the problems of labor-intensive, time-consuming and labor-intensive, and can't open the shed film first, so as to improve work efficiency and save labor. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

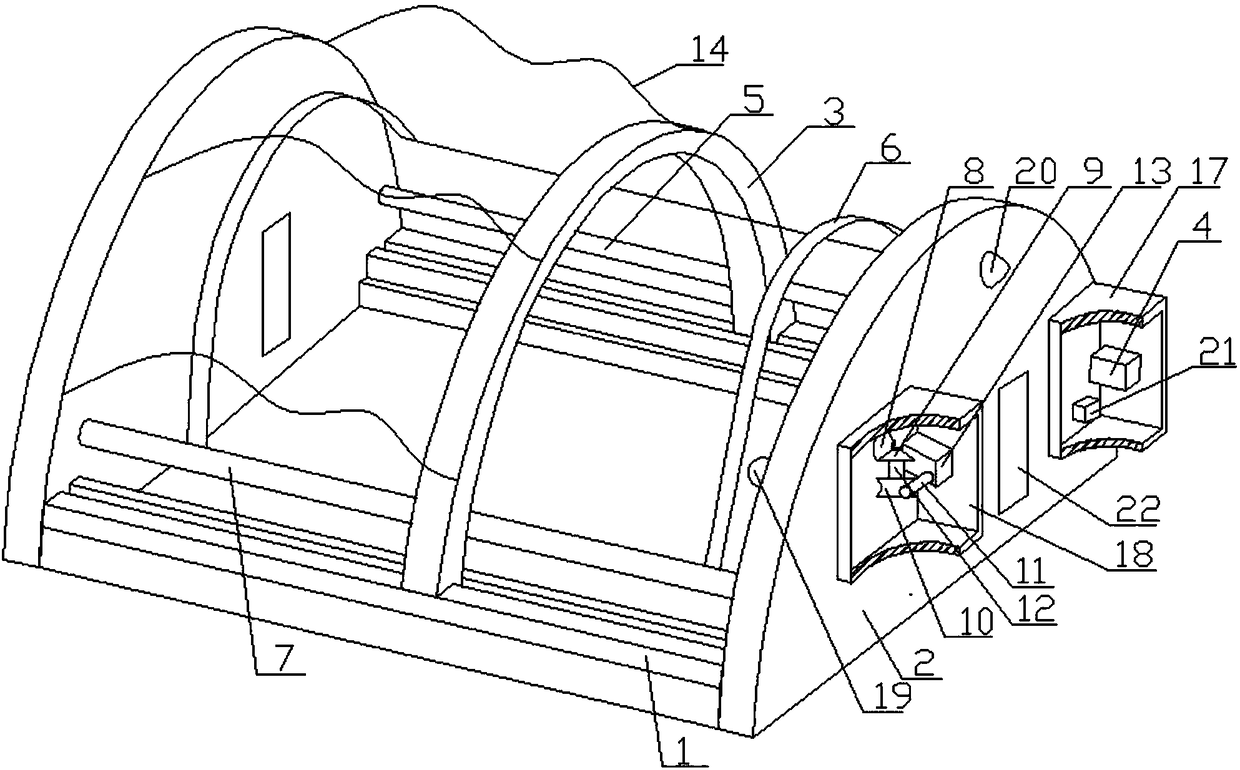

[0024] Below in conjunction with accompanying drawing, technical scheme of the present invention is described in further detail:

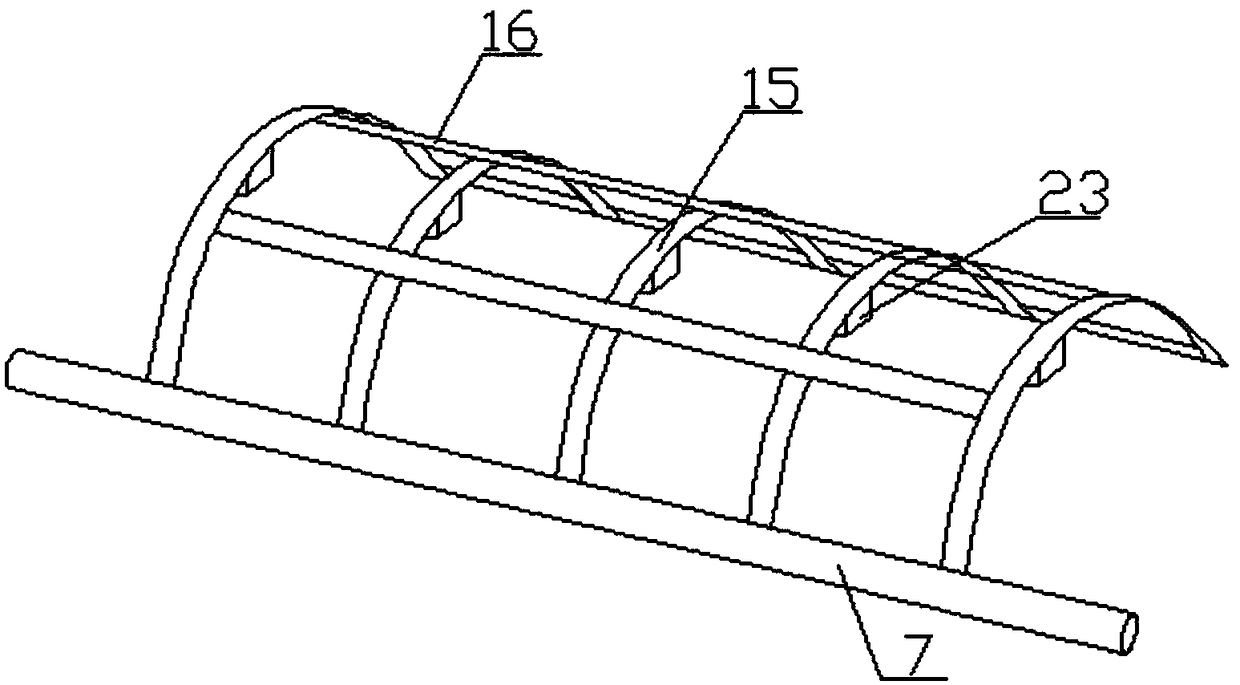

[0025] like figure 1 and figure 2 As shown, an agricultural machinery tent includes a slide rail 1, a support plate 2, a moving frame 3, a motor I4, a ball screw 5, a turret 6, a rotating shaft 7, a bevel gear I8, a bevel gear II9, a turbine 10, and a worm 11 , gear shaft 12, motor II 13 and film 14; the support plate 2 has two and is arranged in parallel, and the support plate 2 is a semicircular structure, and the frame is fixedly connected between the two support plates 2, and the frame is connected to the two A rectangular area is enclosed between the support plates 2; the slide rails 1 have two and are respectively fixedly connected to the frame on both sides of the support plate 2, the mobile frame 3 is a semicircular support, and the two sides of the mobile frame 3 The bottom ends are respectively slidably connected to the two slide rails...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com