Automatic folding mold for sleeve slit

An automatic and mold technology, applied in the direction of sewing tools and other directions, can solve the problems of unguaranteed product quality, complicated operation process, high cost of clothing, and achieve stable and consistent folding size, convenient operation and strong versatility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

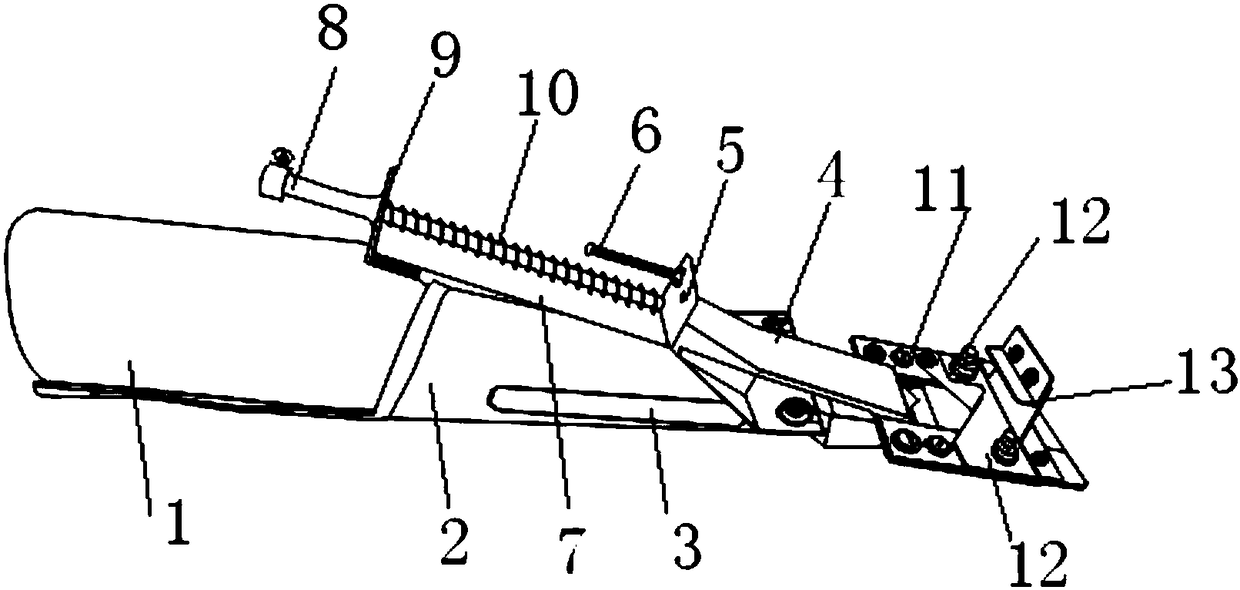

[0016] Such as figure 1 As shown, the present invention mainly includes a cloth guide plate 1, a cloth feeding mechanism and a cloth guiding mechanism.

[0017] The front and rear ends of the fabric guide plate 1 are respectively the cloth inlet end and the cloth outlet end, and the width of the cloth guide plate 1 gradually decreases from the cloth inlet end to the cloth outlet end. The left and right sides of the cloth guide plate 1 are symmetrically provided with a hemming structure 2 that gradually curls inward from the cloth inlet end to the cloth outlet end. In the hem structure 2 , hems are formed by the hem structure 2 .

[0018] The surface of the hemming structure 2 is provided with a strip-shaped adjustment hole 3 from the cloth inlet end to the cloth outlet end. When the cloth strip moves forward from the hem structure 2, it may be blocke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com