Vacuum wall-breaking food processor and self-inspection method thereof

A technology of vacuum wall breaking and cooking machines, which is applied to household machinery for filtering food, household utensils, applications, etc. It can solve the problems of overflowing cup internal pressure, hidden danger cleaning problems, and cup lids that cannot be sealed, so as to facilitate opening and solving Oxidation of food and the effect of preventing potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

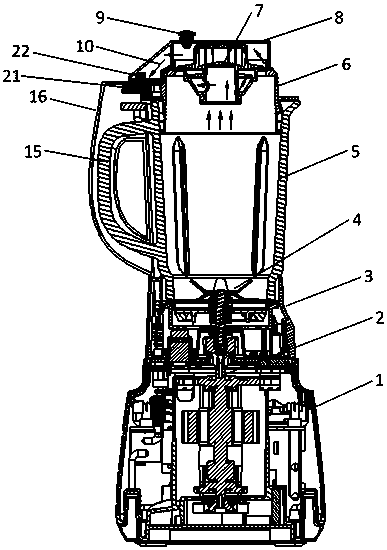

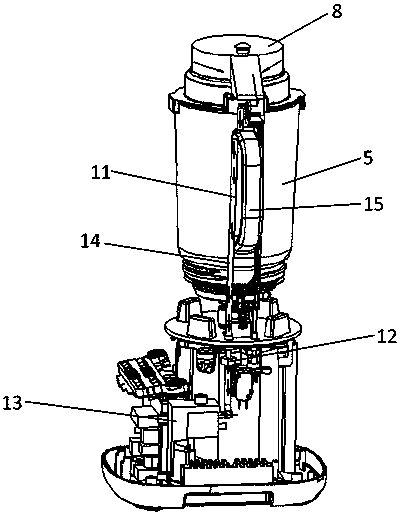

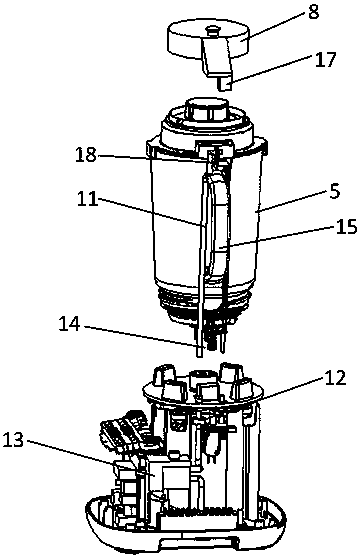

[0058] Below, the present invention is described in detail with reference to accompanying drawing and embodiment:

[0059] Such as Figure 1~8 As shown, a vacuum wall breaking cooking machine includes a casing 1, the upper end of the casing 1 is provided with a cup holder 3, a cup body 5 for wall breaking is installed on the cup holder 3, and a motor 2 is arranged in the casing 1 , the motor 2 drives the cutter head 4, and the cutter head 4 breaks the wall of the food in the cup body 5, and the cup cover 6 is provided with a feeding cover 7 for putting in food. The upper end of the cup cover 6 is provided with a vacuum cover 8 for sealing the cup cover 6 and vacuumizing the cup body 5 .

[0060] Aiming at the problem that the heating cup and the cold-beating cup need to be independently used and designed independently during the use of the wall breaking machine, the present invention uses a cup cover 6 to set a vacuum cover 8 to seal the feeding cover 7 through the vacuum cov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com