Environment-friendly dusting machine for multilayer draped net cover of melt filter

A technology of melt filter and dust remover, which is applied in the direction of dust removal, disperse particle filtration, chemical instruments and methods, etc. It can solve the problems of ineffective collection of dust, incomplete cleaning of net sleeves, easy secondary pollution of net sleeves, etc. Achieve the effect of avoiding secondary pollution, prolonging service life and solving cleaning problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described now in conjunction with accompanying drawing.

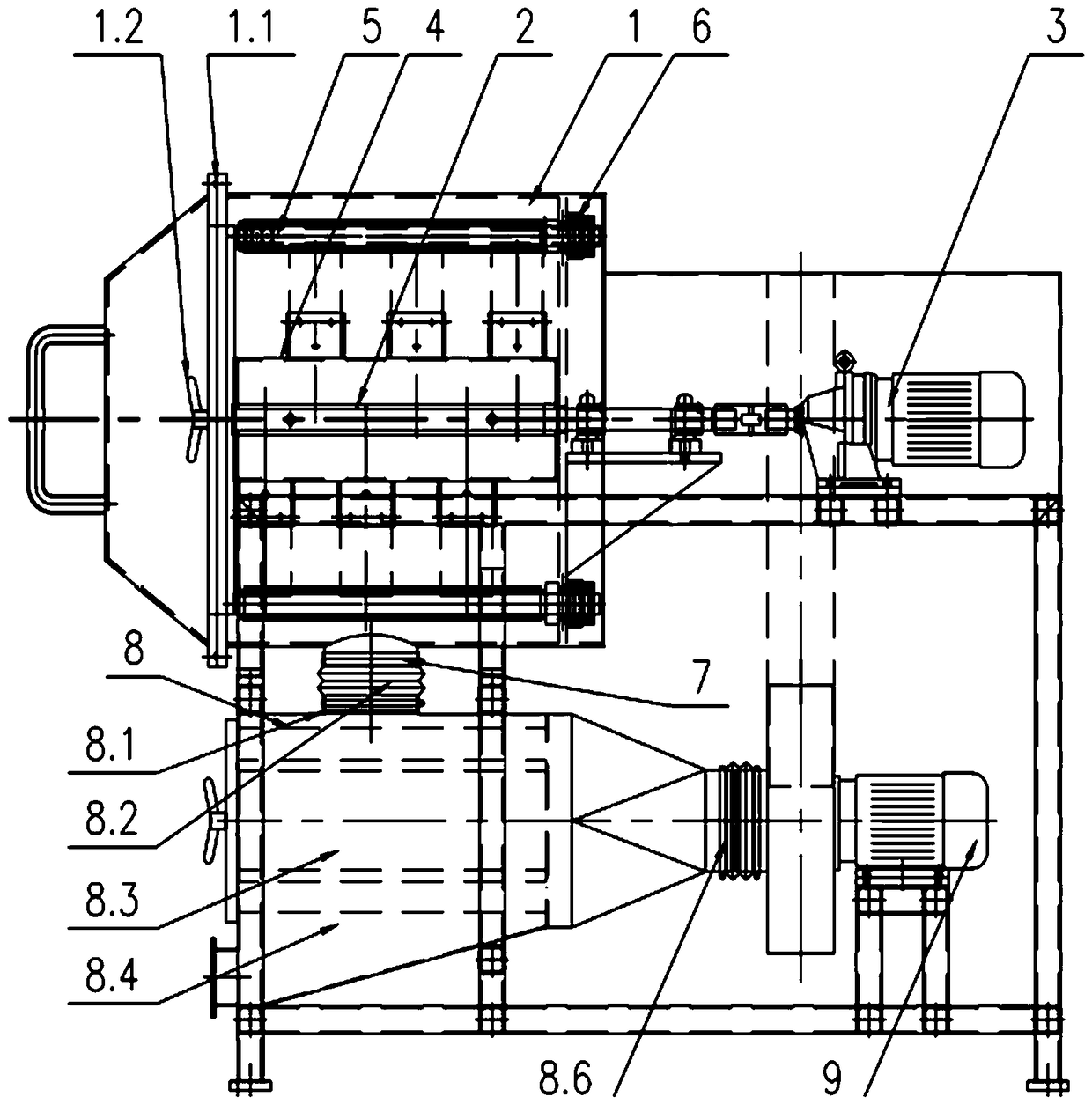

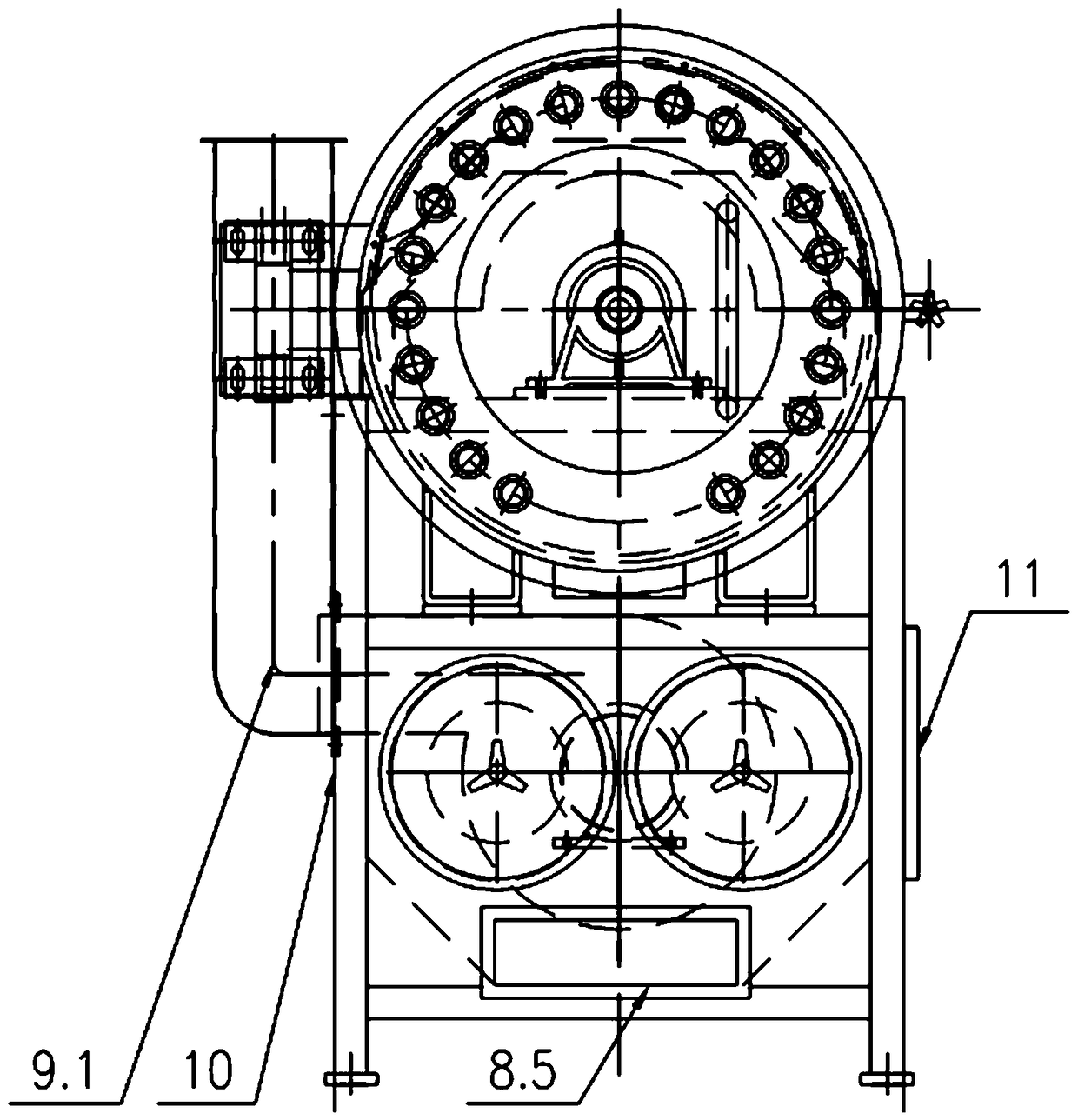

[0021] as attached figure 1 and figure 2 , the present invention is an environmental protection dedusting machine with multi-layer skirt wrinkle net cover for melt filter, comprising a frame, a sealing cavity 1 is installed on the frame, a sealing gasket 1.1 and a sealing and locking device 1.2 are arranged on the sealing cavity 1, A transmission shaft 2 is arranged in the center of the sealing chamber 1, and the transmission shaft 2 is connected with the transmission motor 3 outside the sealing chamber, and a roller 4 is arranged inside the sealing chamber 1, and several rubber flaps are installed on the outer circumference of the roller 4; A plurality of connecting rods 5 are installed in the cavity, and the connecting rods 5 have several small holes in the radial direction, and one end of the connecting rods 5 is closed and the other end is connected outside the sealed c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com