Oil and gas separator with unpowered turbine

An oil-vapor separation and power turbine technology, which is applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve problems such as unsatisfactory tar removal effect, high operating cost, and environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

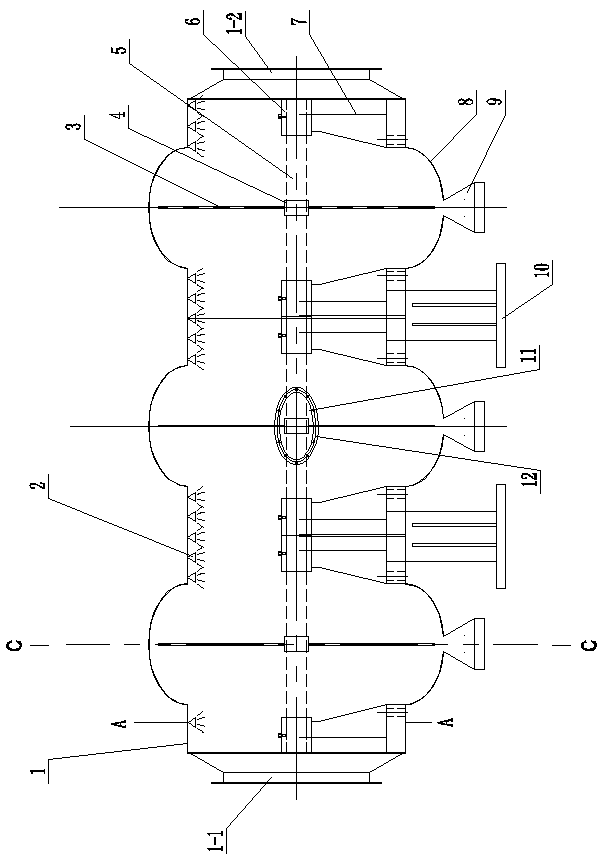

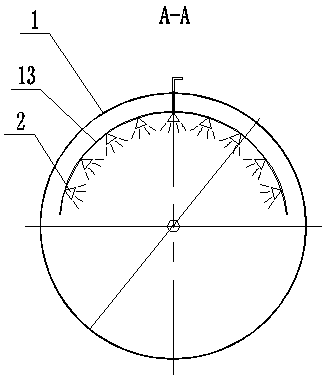

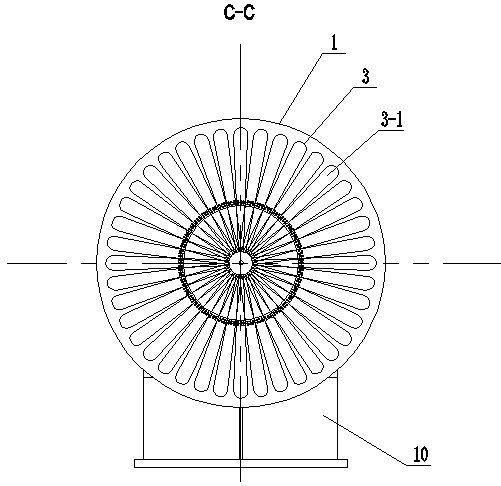

[0019] Such as figure 1 As shown in -5, the unpowered turbine oil-steam separator includes a horizontally arranged cylinder body 1, one end of the cylinder body 1 is the inlet port 1-1, and the other end is the outlet port 1-2, and the saddle is connected under the cylinder body 1 Seat 10. Three sections of buffer chambers 8 protruding outward are arranged on the cylinder body 1 , the inner diameter of the buffer chambers 8 is larger than the inner diameter of the cylinder body 1 , and the lower ends of each buffer chamber 8 are respectively connected to the collecting tank 9 .

[0020] An inner shaft 5 and four bearing support frames 7 are arranged in the barrel body 1, each bearing support frame 7 is fixedly connected with the barrel body 1, the inner shaft 5 is arranged horizontally, and the inner shaft 5 is supported on each bearing through the bearing seat 6 on the support frame 7. A shaft sleeve 4 and an impeller 3 are arranged in each buffer chamber 8, and the shaft s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com