Ferrous metallurgy environment-friendly waste gas treatment device

A technology of environmental protection treatment and iron and steel metallurgy, which is applied in the direction of gas treatment, dispersed particle separation, membrane technology, etc., can solve the problems of unsatisfactory requirements, defects, accident prevention and rescue measures, etc., so as to improve the adsorption effect and improve area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

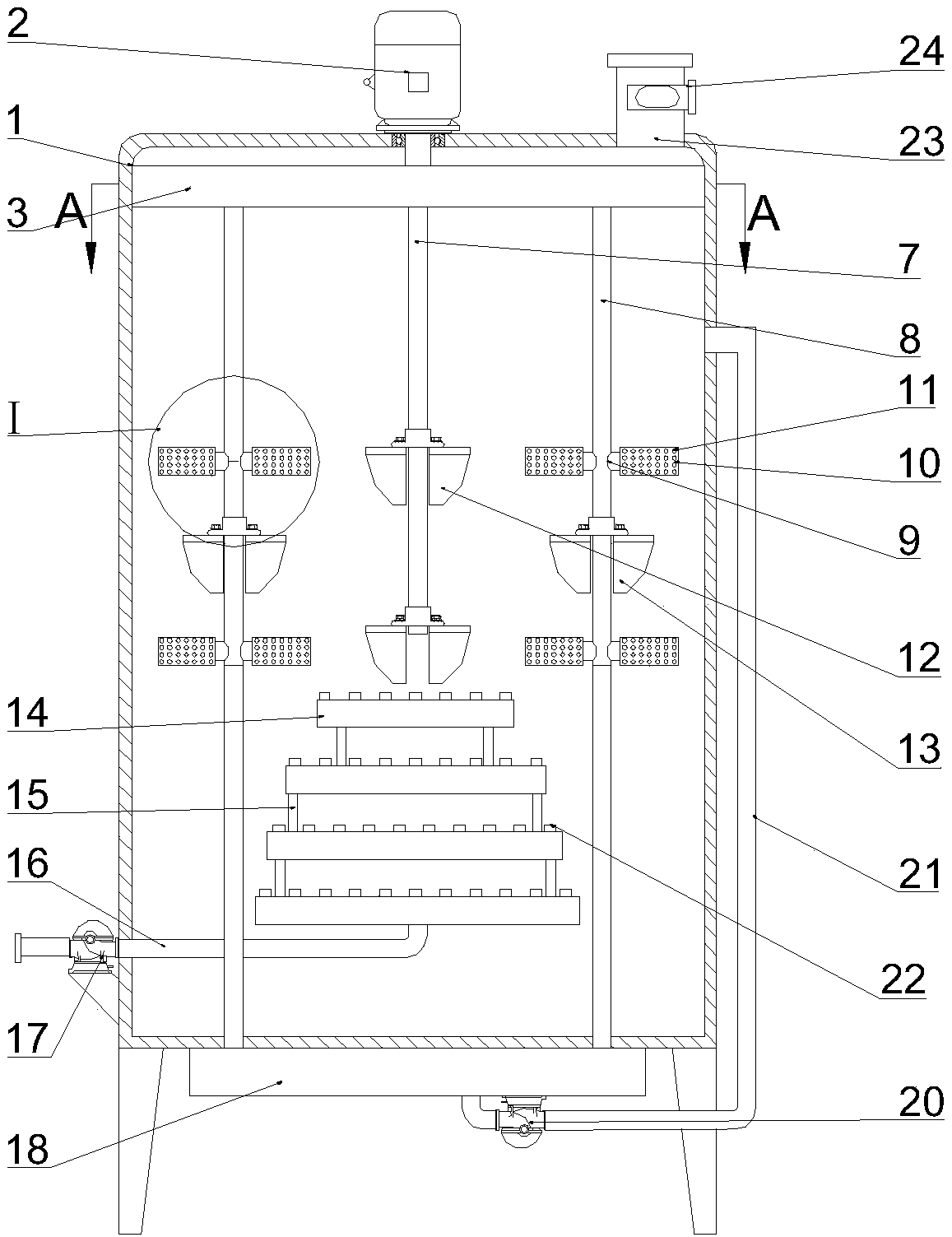

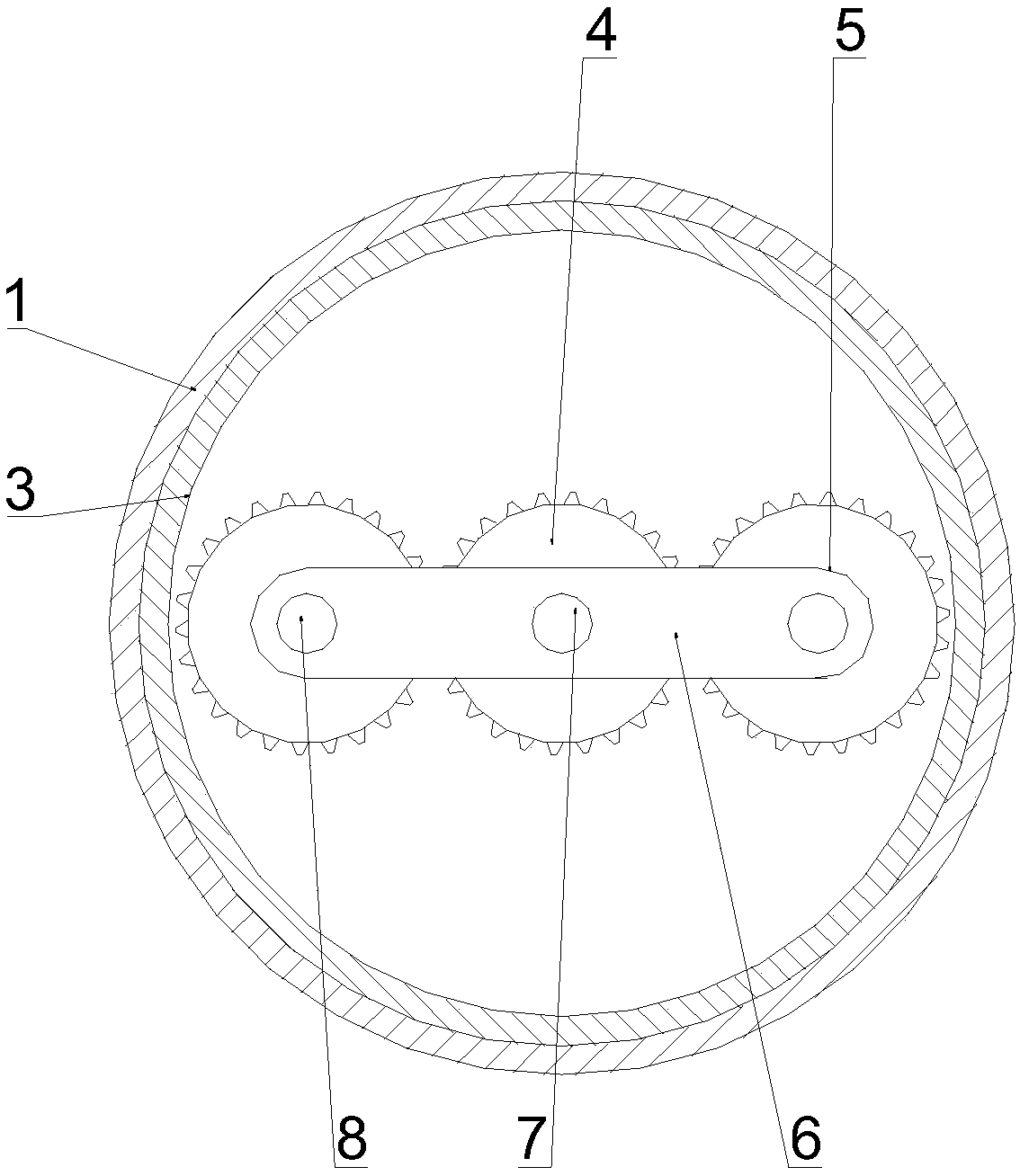

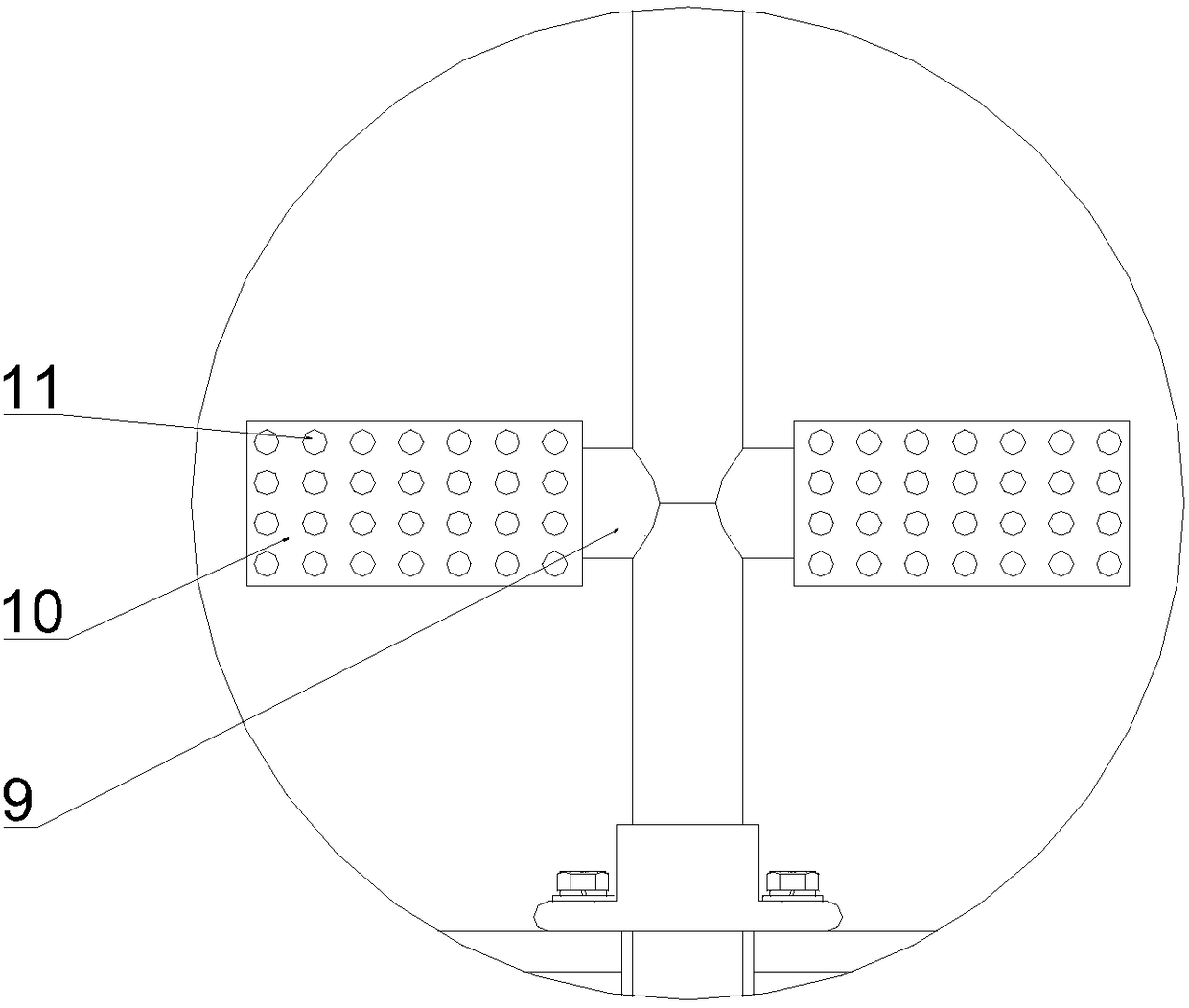

[0026] see Figure 1-4 , an environmental protection treatment equipment for iron and steel metallurgical waste gas, comprising a box body 1, the interior of the box body 1 is provided with a rotating shaft 7 that is rotatably connected to the upper side wall of the box body 1, and the surface of the rotating shaft 7 is fixedly connected with a first stirring Paddle 12, the upper side of the inner wall of the box body 1 is fixedly connected with the installation box 3, and the installation box 3 is provided with a driving gear 4 and several driven gears 5 meshed with the driving gear 4, and the rotating shaft 7 The upper part is fixedly installed in the mounting hole of the driving gear 4, and a hollow tube 8 is fixedly connected in the mounting hole of the driven gear 5, and the other end of the hollow tube 8 is connected in rotation with the lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com