High-flow ultrasonic fine atomization nozzle

A technology of atomizing nozzles and large flow, applied in the direction of spraying devices, liquid spraying devices, spraying devices with movable outlets, etc., can solve the problems of uneven particle size distribution and spatial distribution of large-flow wet saturated steam droplets, and achieve Solve the effect of uneven particle size, uniform distribution and uniform particle size of water droplets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

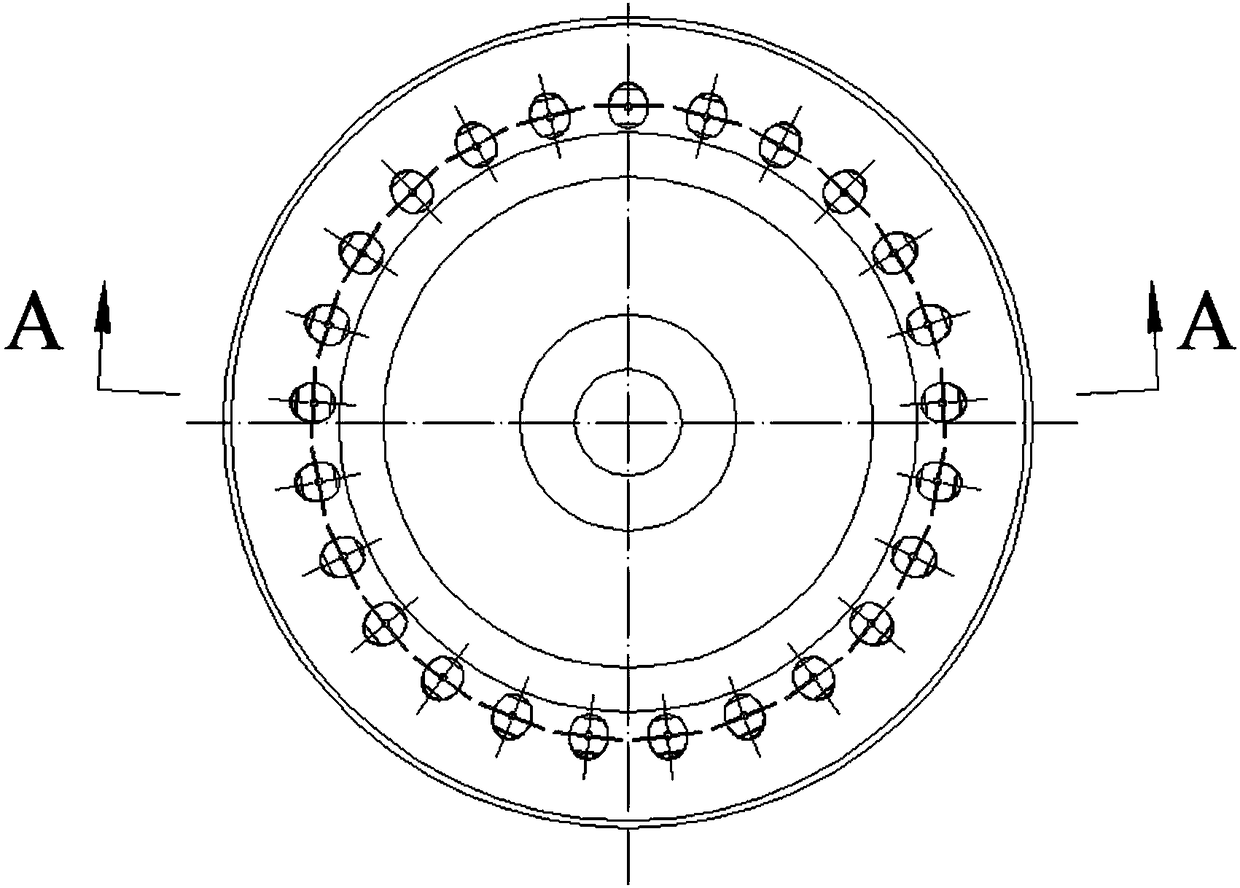

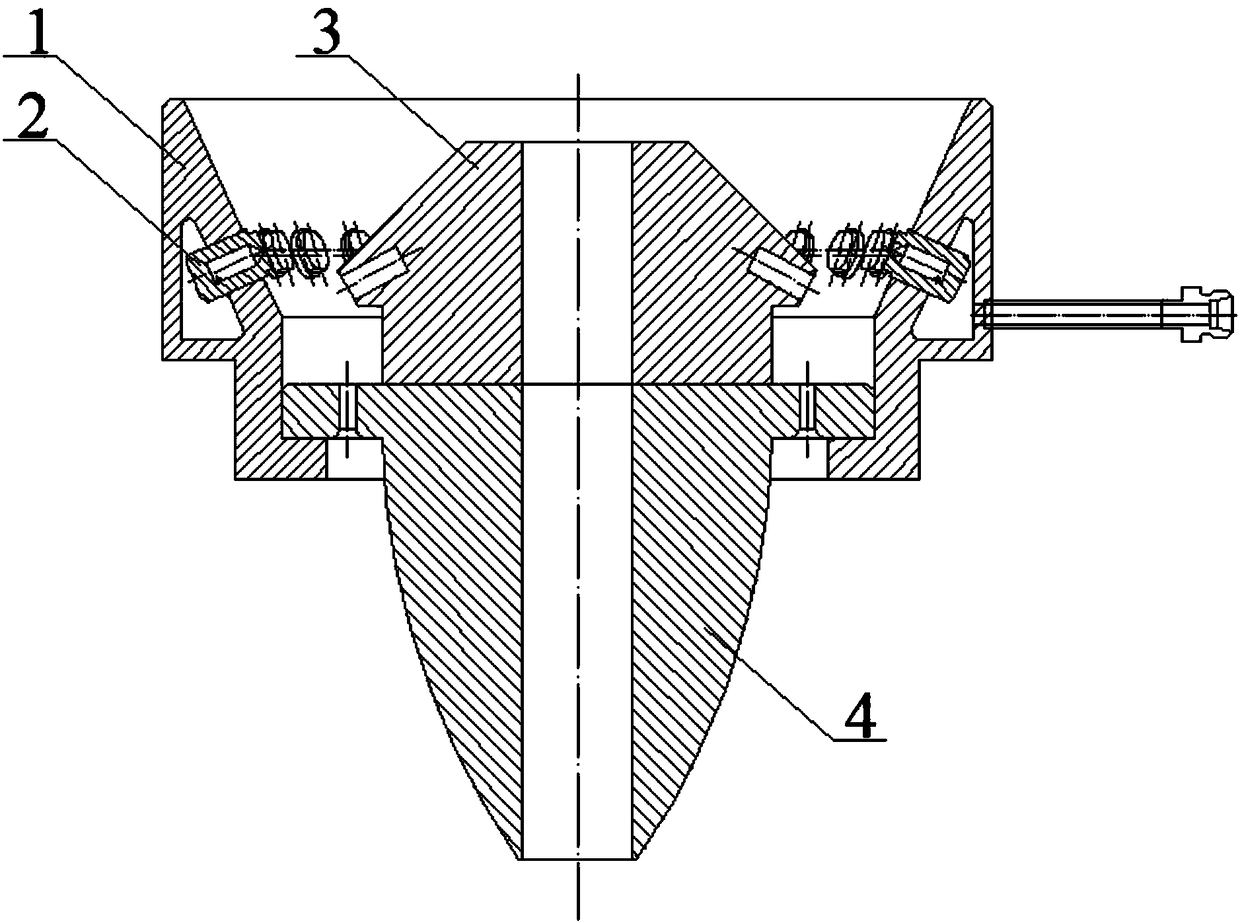

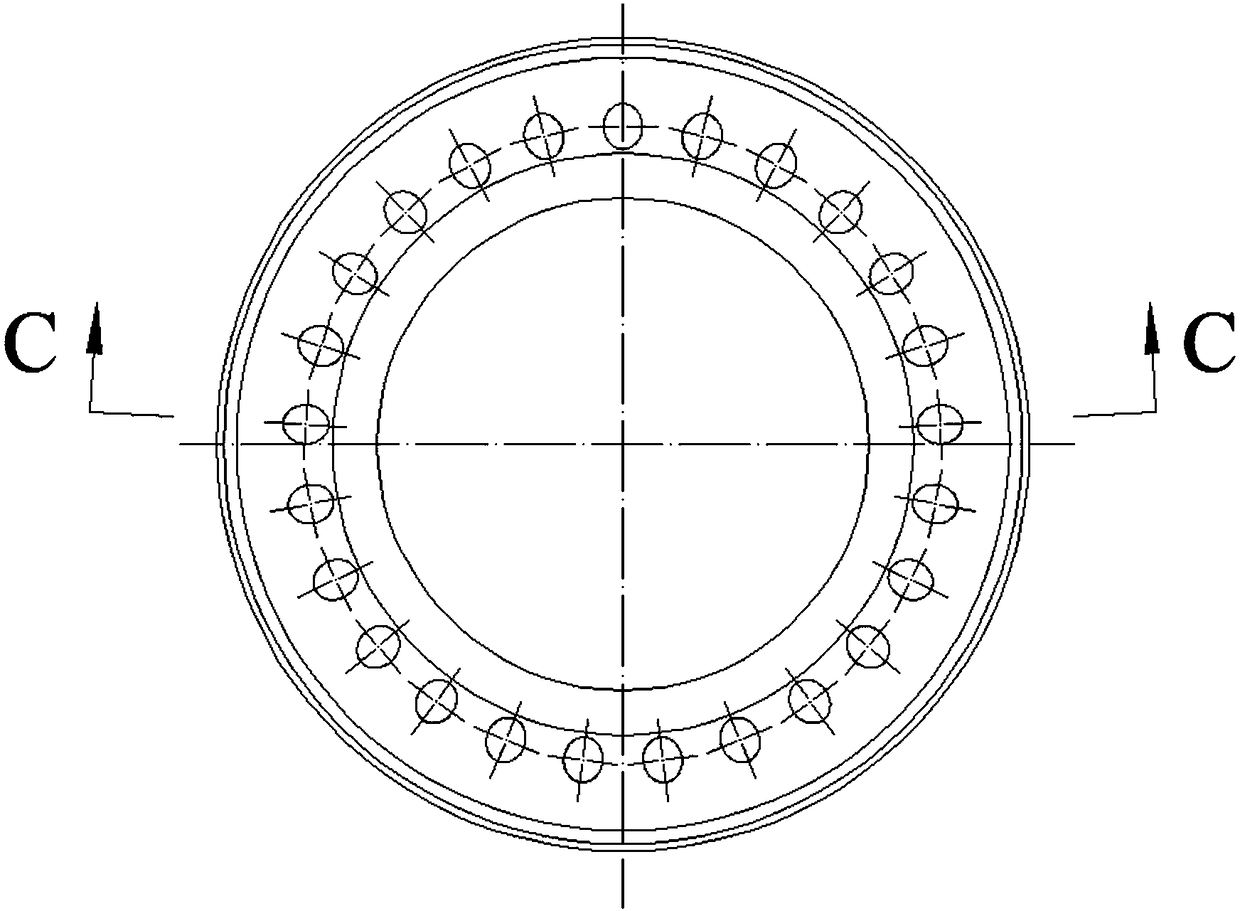

[0025] Specific implementation mode one: combine Figure 1-10 Illustrate that this embodiment is large, and the large-flow ultrasonic fine atomization nozzle of this embodiment is made of nozzle outer ring 1, centrifugal nozzle 2, ultrasonic generator 3, nozzle body 4;

[0026] The nozzle outer ring 1 is circular, the lower part of the nozzle outer ring 1 is a cylindrical chamber, the upper part of the nozzle outer ring 1 is a conical opening, the outer wall of the conical opening is cylindrical, the inner wall of the conical opening and the circumferential A water inlet channel 1-1 with a triangular cross-section is arranged between the outer walls; a high-pressure water inlet pipe 1-4 communicating with the water inlet channel 1-1 is arranged on the outer wall of the water inlet channel 1-1; the cylinder at the lower part of the nozzle outer ring 1 The inner surface of the lower part of the shaped chamber is provided with a positioning ring 1-3;

[0027] The center of the c...

specific Embodiment approach 2

[0033] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is: the inner wall of the tapered opening of the nozzle outer ring 1 is provided with threaded holes 1-2, and the centrifugal nozzle 2 is provided with a threaded hole 1-2 on the inner wall of the tapered opening. The provided threaded holes match the external threads, and the nozzle outer ring 1 and the centrifugal nozzle 2 are threadedly connected. Other steps and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

[0034] Specific embodiment three: the difference between this embodiment and specific embodiment one is: the connection mode between the lower end surface of the ultrasonic generator 3 and the upper surface of the nozzle body 4 is welding. Other steps and parameters are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com