Environmental muffler

A kind of muffler, environmental protection technology, applied in the direction of instruments, sound equipment, chemical instruments and methods, etc., can solve the problems of blockage of muffler holes and reduction of noise reduction ability of mufflers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following is further described in detail through specific implementation methods:

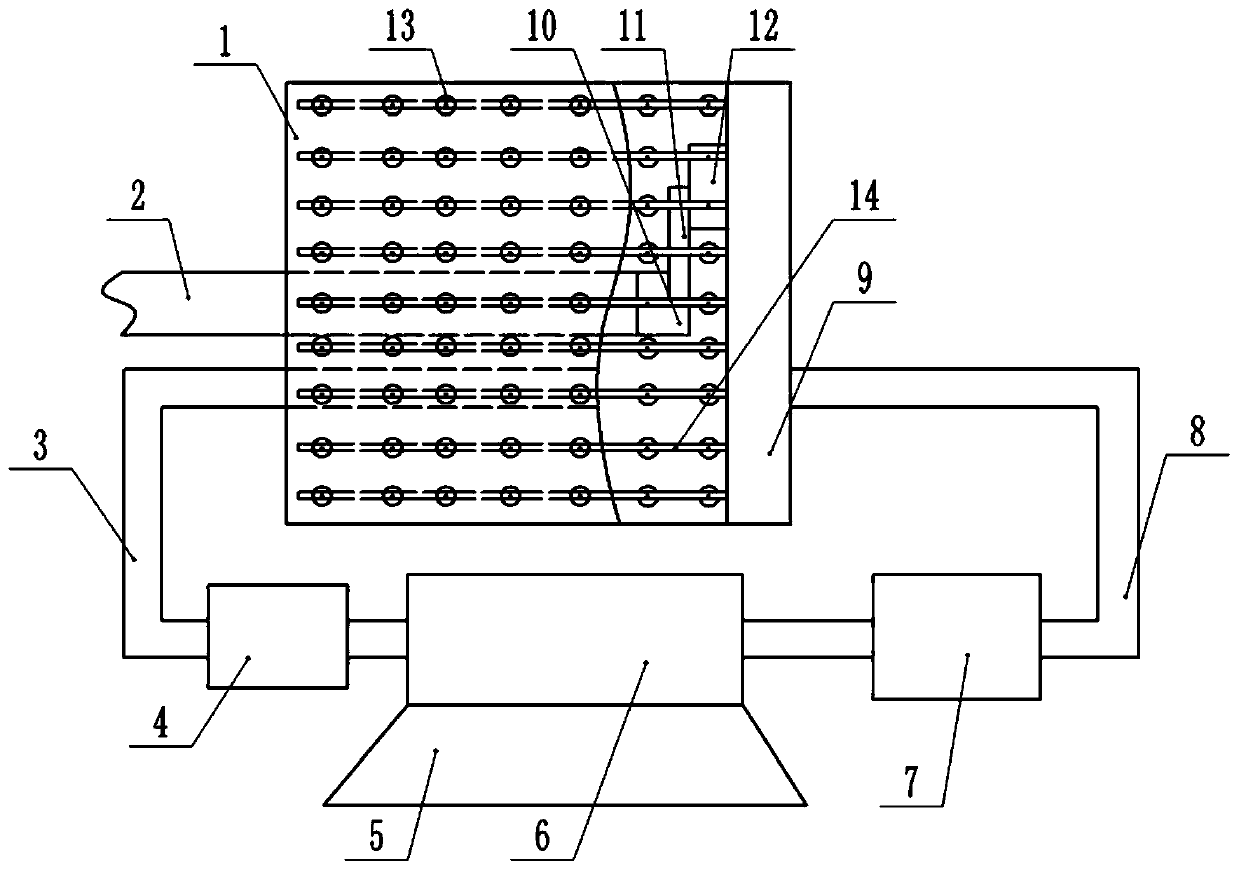

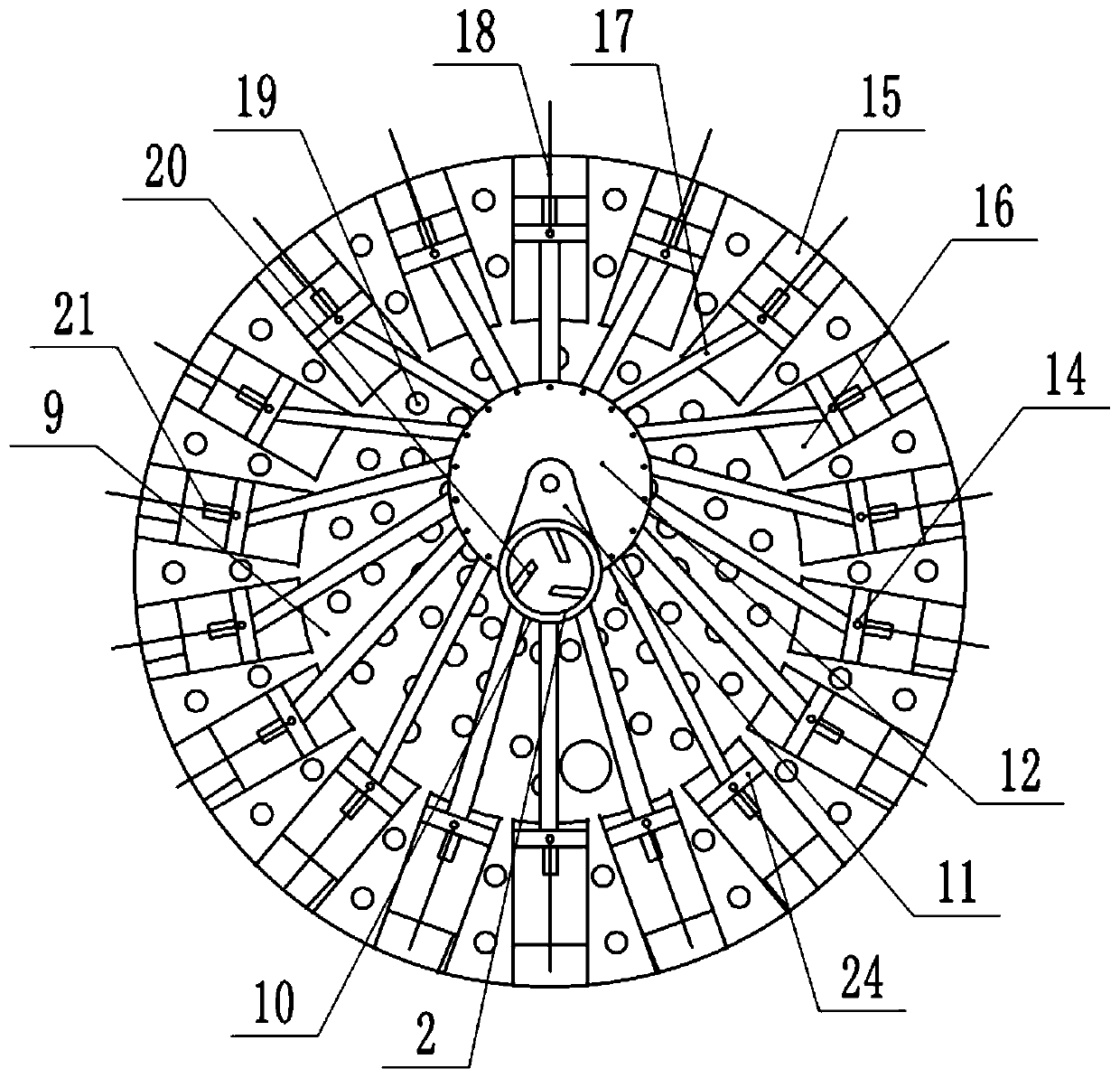

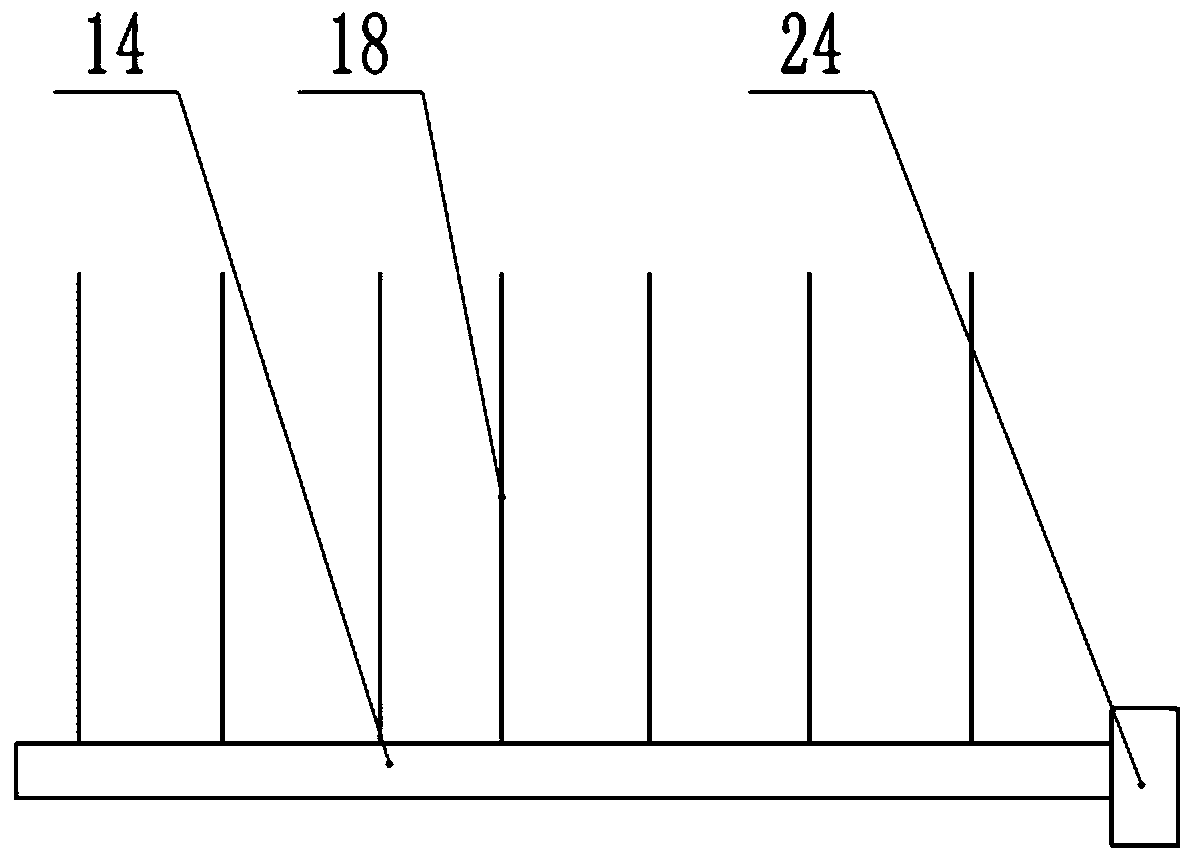

[0018] The reference signs in the drawings of the description include: silencer pipe 1, connecting pipe 2, water inlet pipe 3, water pump 4, fixing seat 5, water tank 6, cooling tank 7, water outlet pipe 8, baffle plate 9, rotating pipe 10, connecting plate 11. Revolving plate 12, silencer hole 13, long rod 14, sound box 15, chute 16, piston rod 17, pin 18, through hole 19, fan blade 20, knock rod 21, piston head 24.

[0019] The embodiment is basically as attached Figure 1-Figure 3 Shown: the environment-friendly muffler includes a muffler pipe 1 and a connecting pipe 2. The pipe wall of the muffler pipe 1 is provided with a number of muffler holes 13, and the muffler holes 13 on the muffler pipe 1 can be eighteen rows, seven in each row. The left end of the connecting pipe 2 is located outside the muffler pipe 1, the right end of the connecting pipe 2 is located inside the muffle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com