Airlift external loop reactor and method

An external circulation, air-lift technology, applied in chemical instruments and methods, organic chemistry, chemical/physical processes, etc., can solve problems such as increasing equipment cost and system complexity, and achieve simple structure, small power consumption, guarantee The effect of directional flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

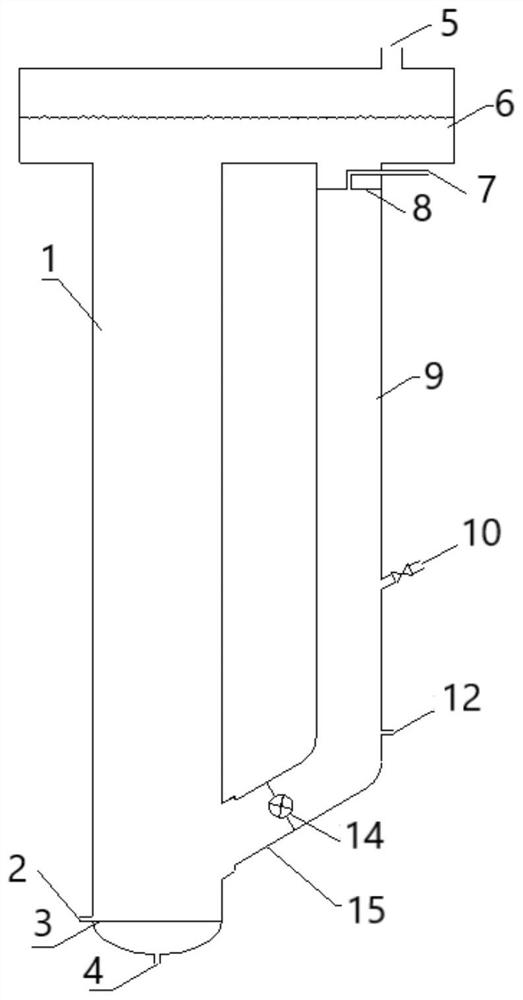

[0044] use figure 1 Reactor, the pressure in the reactor is about 10Barg, and the hydroformylation reaction is carried out in the riser, and the flat temperature is 80°C, and the catalyst is a rhodium-based catalyst (a rhodium-based homogeneous catalyst prepared in the laboratory, wherein rhodium Rh: bisphosphine complex Body 2P: Triphenylphosphine PPh 3 The ratio is 1:4:100), the liquid inlet feed is the toluene solution of allyl alcohol (the mass fraction of allyl alcohol is 20wt%), the mass flow rate is 2.5kg / hr, and the mixed gas flow rate is 3Nm 3 / hr (the molar ratio of hydrogen to carbon monoxide is 1:1), the conversion rate of allyl alcohol in the riser is 99.9%, and the selectivity of the target product 4-hydroxybutyraldehyde is 95%.

[0045] The hydrogenation reaction is carried out in the downcomer, the average temperature is 150°C, the catalyst is a weakly acidic acrylic cation exchange resin catalyst (Tianjin Bohong Resin Technology Co., Ltd., model: D113), and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com