A device and method for growing nitride crystals

A nitride crystal and growth method technology, applied in crystal growth, single crystal growth, single crystal growth, etc., can solve the problems of unfavorable crystal growth dynamic balance, crystal growth solution and seed crystal movement violently, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

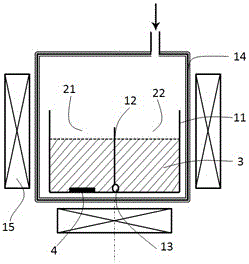

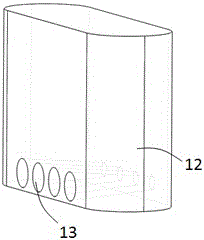

[0037] Embodiment one, as attached Figure 4 with 5 As shown, a method for growing a nitride crystal comprises the following steps:

[0038] Step 1, place raw materials in the crucible 11, feed nitrogen into the reactor, place the seed crystal on the bottom of the growth area, then seal the reactor, heat up and pressurize the reactor, the pressure and temperature only need to meet the growth requirements of the seed crystal That is, this is common knowledge in the art, and will not be described in detail here. Since the growth solution in the upper part of the crucible has more dissolved N, its N concentration is higher than that in the growth solution in the lower part of the crucible, and the growth solution near the bottom seed crystal is consumed by the growing crystal, so the N concentration is also relatively low. Low. At this time, the growth solution containing N concentration at the gas-liquid interface in the growth zone is higher than the N concentration in the g...

Embodiment 2

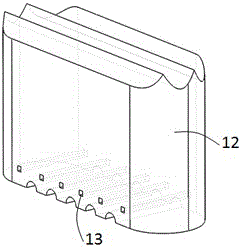

[0042] Embodiment two, as attached Image 6 with 7 As shown, a method for growing a nitride crystal, the difference between the second embodiment and the first embodiment mainly lies in that the direction of inclination of the reactor is different, as follows:

[0043] Step 1, place raw materials in the crucible 11, feed nitrogen gas into the reactor, place seed crystals on the bottom of the growth zone, heat up and pressurize the reactor, and the concentration of N in the growth solution at the gas-liquid interface in the growth zone is higher than that in the growth zone The growth solution in the lower part contains N concentration, and the N concentration in the growth solution at the gas-liquid interface of the pre-growth zone is higher than that in the growth solution in the lower part of the pre-growth zone.

[0044] Step 2. Shake the reactor to tilt the reactor along the direction of the pre-growth zone. After reaching the predetermined angle of inclination, keep the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com