Cutter bar assembling machine and automatic assembling equipment

A technology of assembling machine and cutter bar, applied in the direction of assembling machine, metal processing equipment, manufacturing tools, etc., can solve the problems of increased manufacturing cost, low assembly accuracy, high labor cost, and achieve reduced labor cost, high assembly efficiency, and assembly accuracy. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

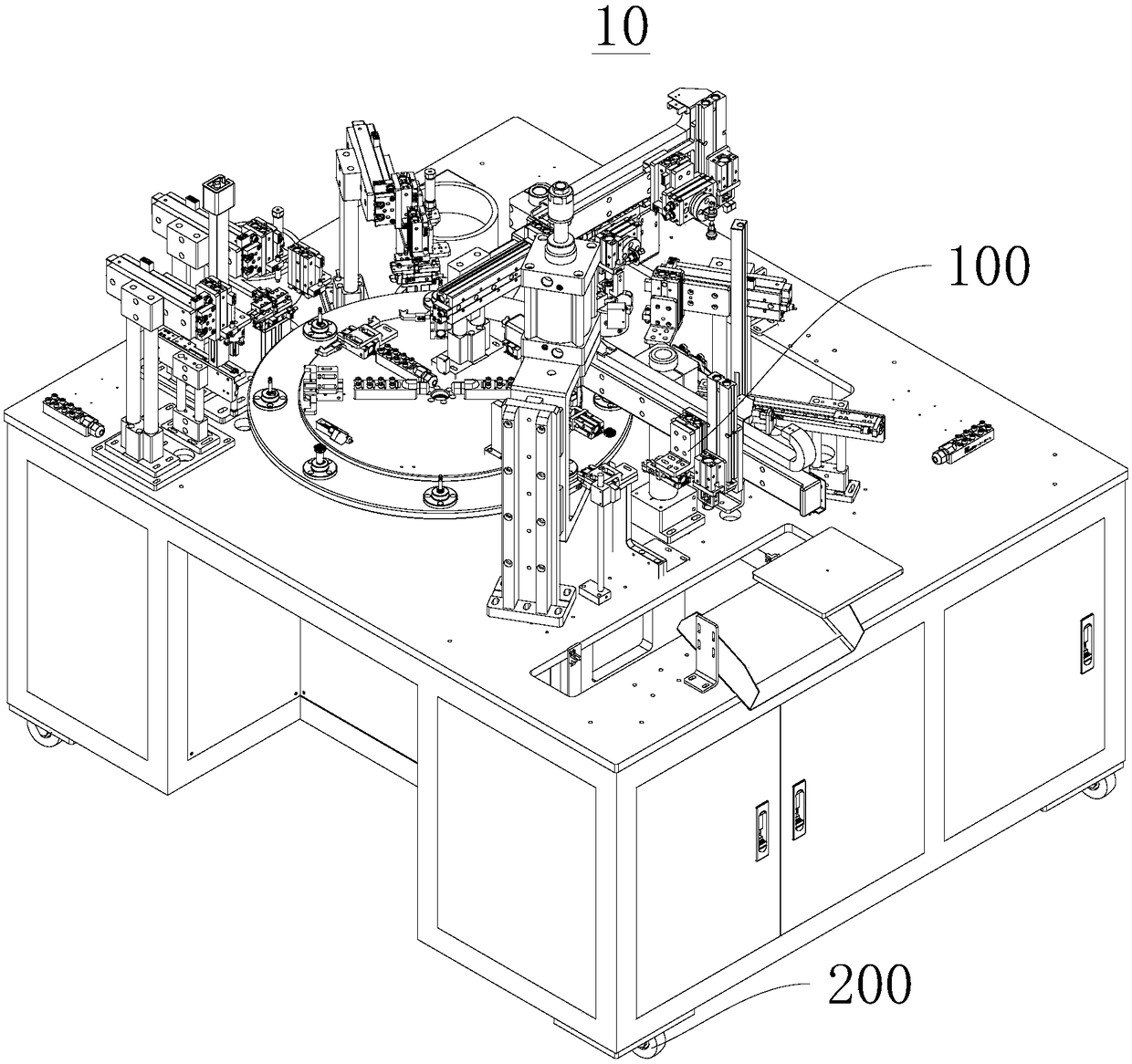

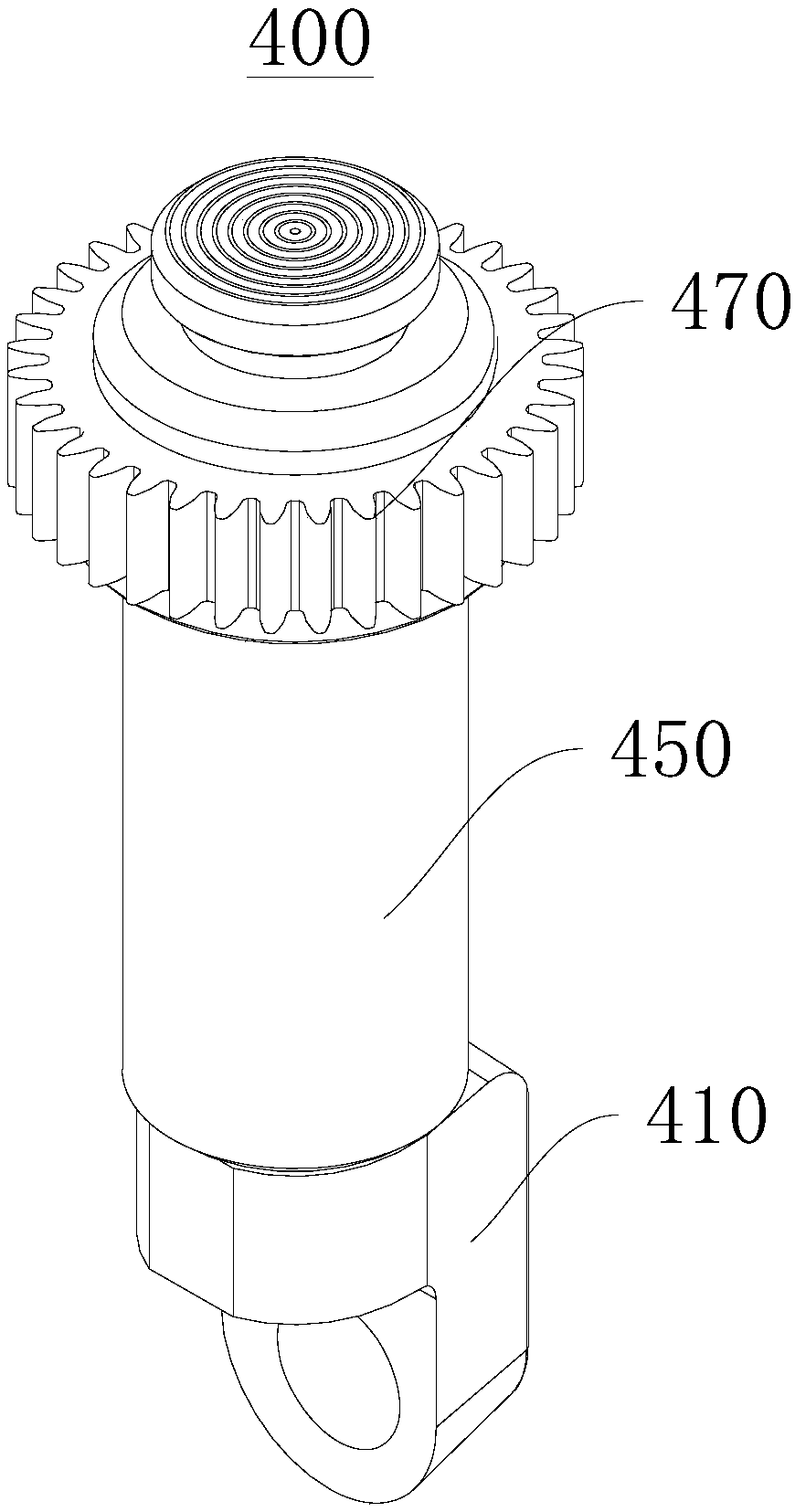

[0036] Please refer to figure 1 , figure 2 with image 3 , An embodiment of the present invention provides an automated assembly device 10 for assembling a knife bar 400. It can automatically complete the assembly between the various parts of the cutter bar 400, has high assembly efficiency, high assembly accuracy, reduced labor costs, strong practicability, and high cost performance. The automated assembly equipment 10 includes a universal wheel 300 and a knife bar assembly machine 100. The universal wheel 300 is installed at the bottom of the tool bar assembling machine 100 to facilitate the movement and transportation of the tool bar assembling machine 100. The tool bar assembly machine 100 is used to assemble various components to form a tool bar 400.

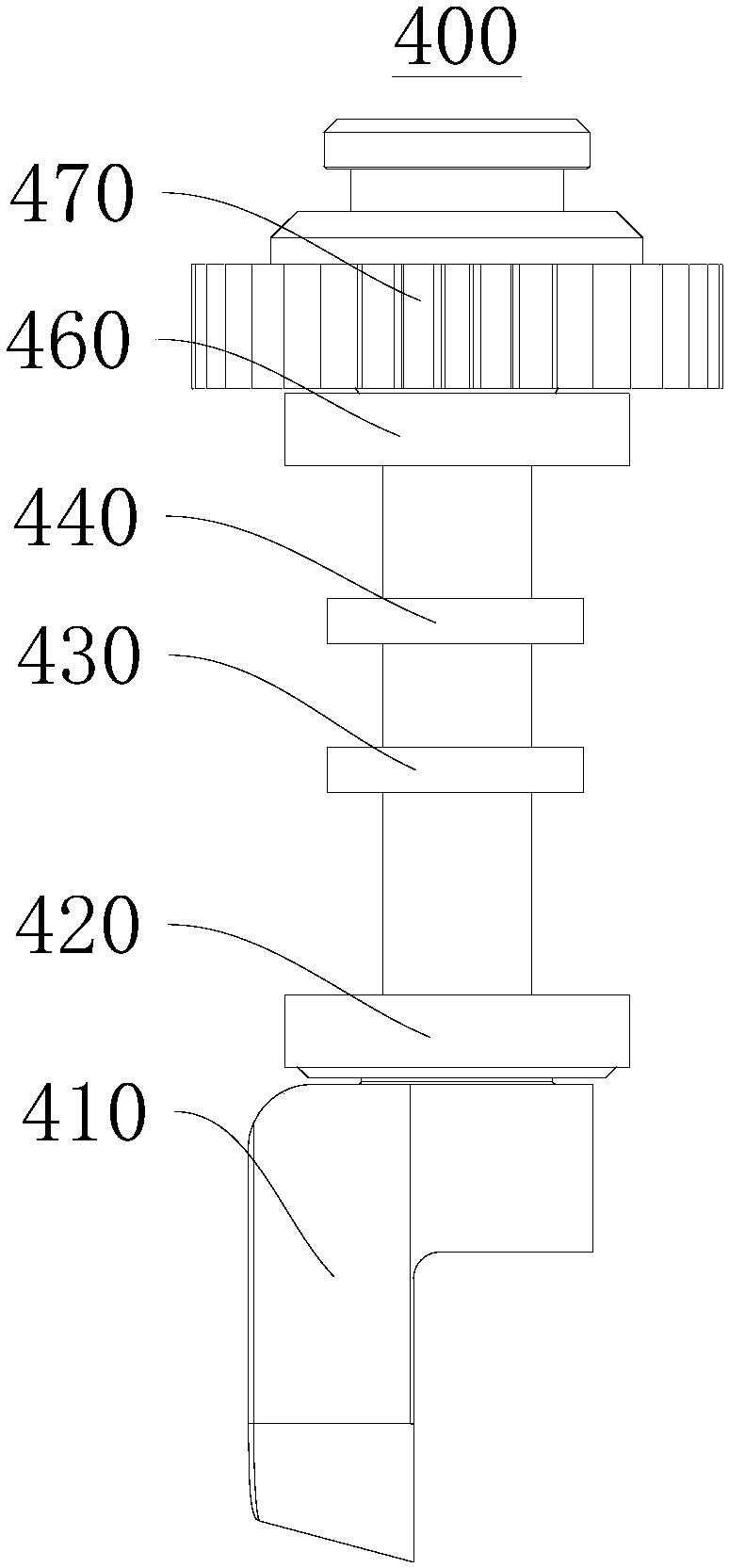

[0037] In this embodiment, the knife bar 400 is a part of the paper cutter, and is used to drive the knife body to perform paper cutting operations. The tool bar 400 includes a body 410, a first bearing 420, a first sealing...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap