chip removal tool

A cutting tool and flute technology, which is applied to milling cutters, manufacturing tools, metal processing equipment, etc., can solve the problem of incomplete chip discharge, prevent chips from staying inside the workpiece, and maintain cutting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019]The present invention will be further described below with reference to the accompanying drawings.

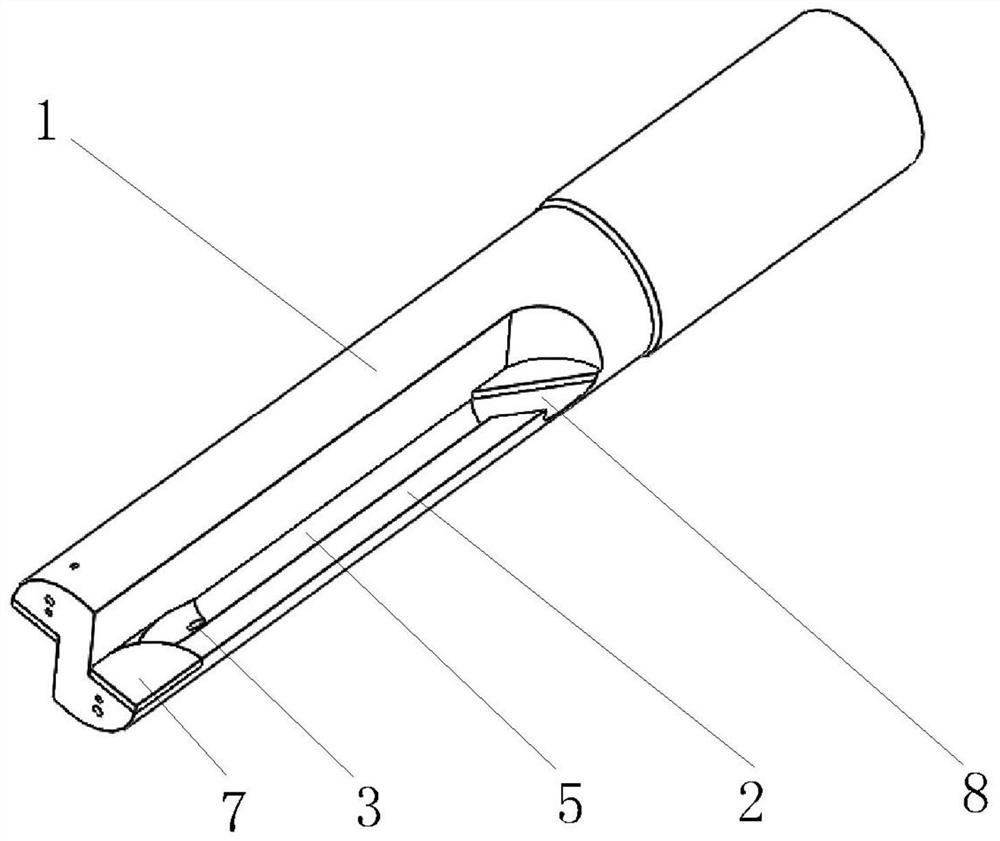

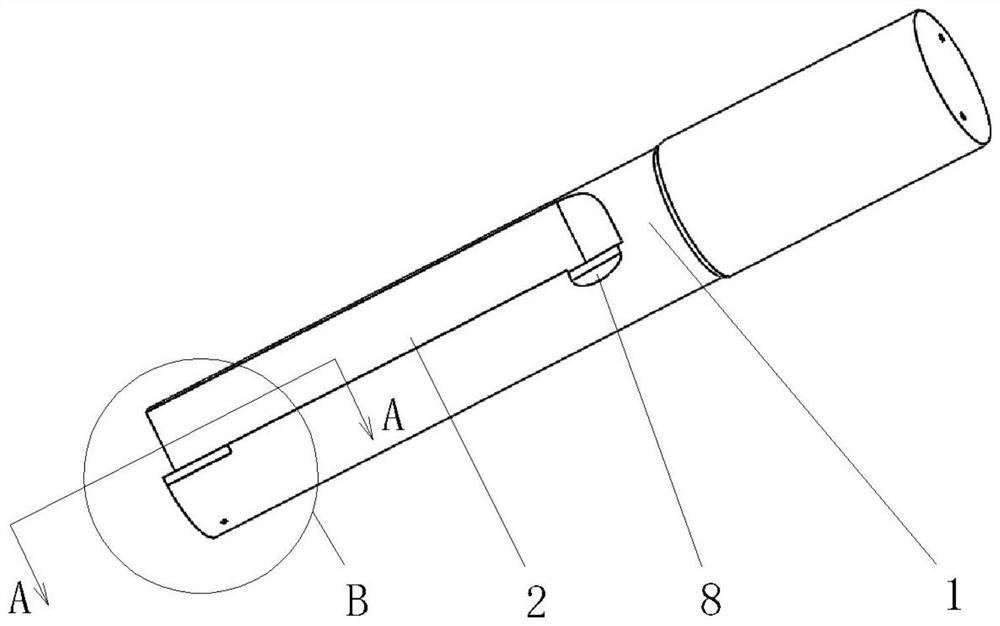

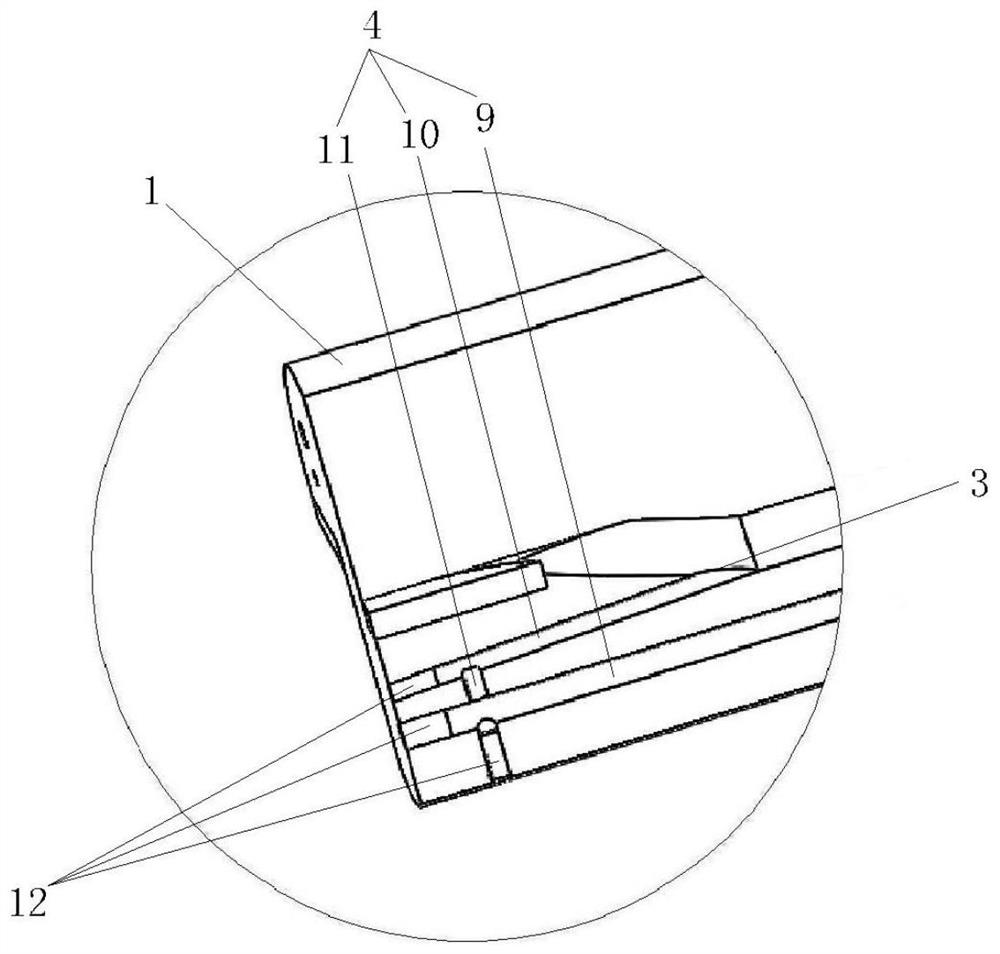

[0020]Such asfigure 1 withfigure 2 A chip cutting tool shown in the middle, including the columnar blade body 1, the front end of the columnar blade body 1 is provided with a cutting edge, and a tandem groove 2, a chip chip groove 2, a chip slot, a chip sloucher matches the cutting edge. 2 Self-cutting edges extend backward, characterized in that the chopper groove 2 is provided with a coolant outlet 3 towards the rearwardly rearward; the columnar blade body 1 is provided with a cooling liquid 4, the coolant outlet 3 and the cooling liquid 4 communicate . At the time of use, there is high-speed high-pressure coolant in the cooling liquid 4, which is advantageous to take away the heat generated during processing, the high pressure coolant is ejected from the coolant outlet 3; the front end of the columnar knife 1 The cutting edge is constantly cutting on the workpiece, and a large ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com