Workpiece hole position marking tool

A workpiece hole and marking technology, which is applied in the field of tooling and fixtures, can solve the problems of low hole position accuracy, and achieve the effect of improving machining accuracy and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

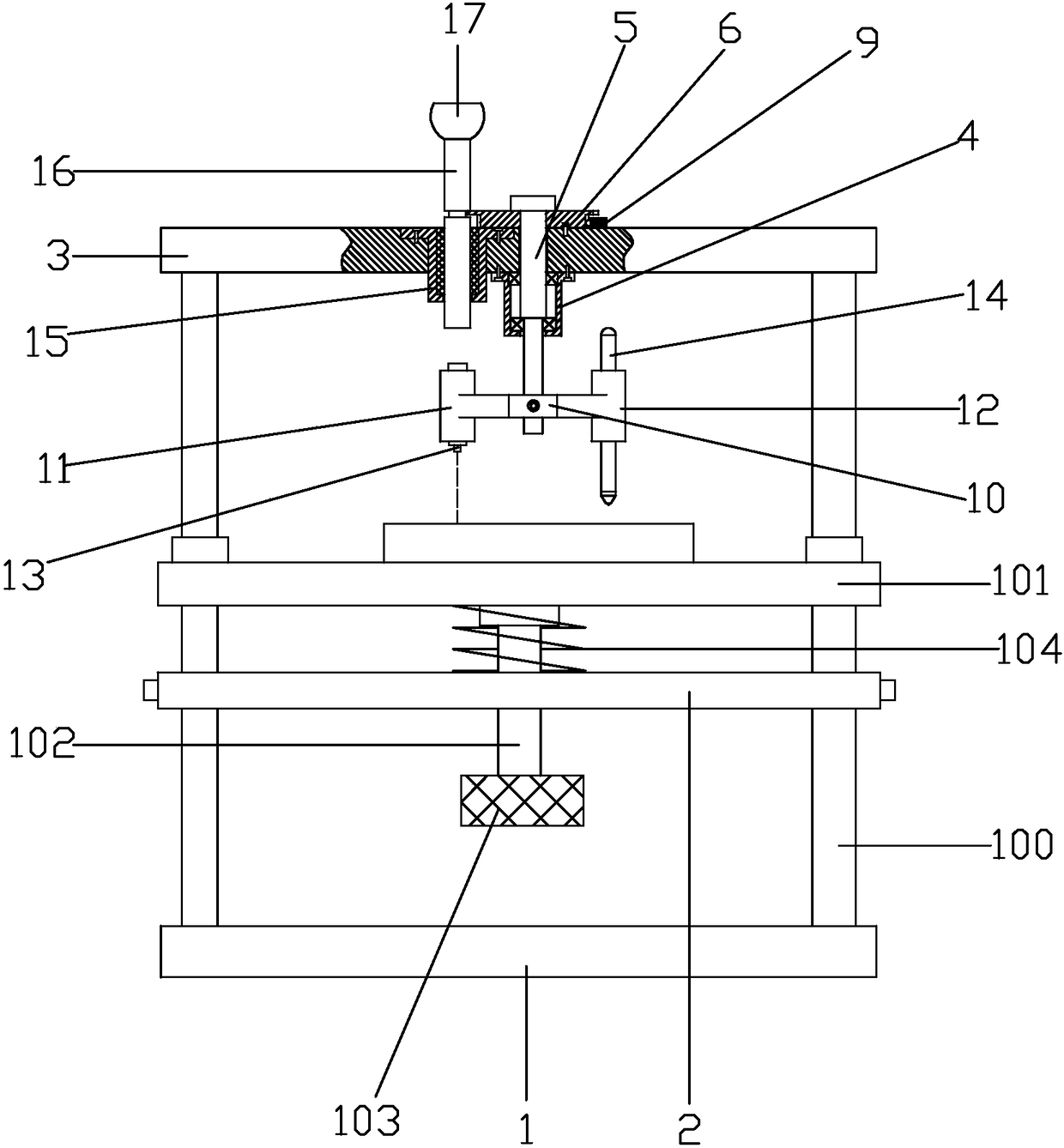

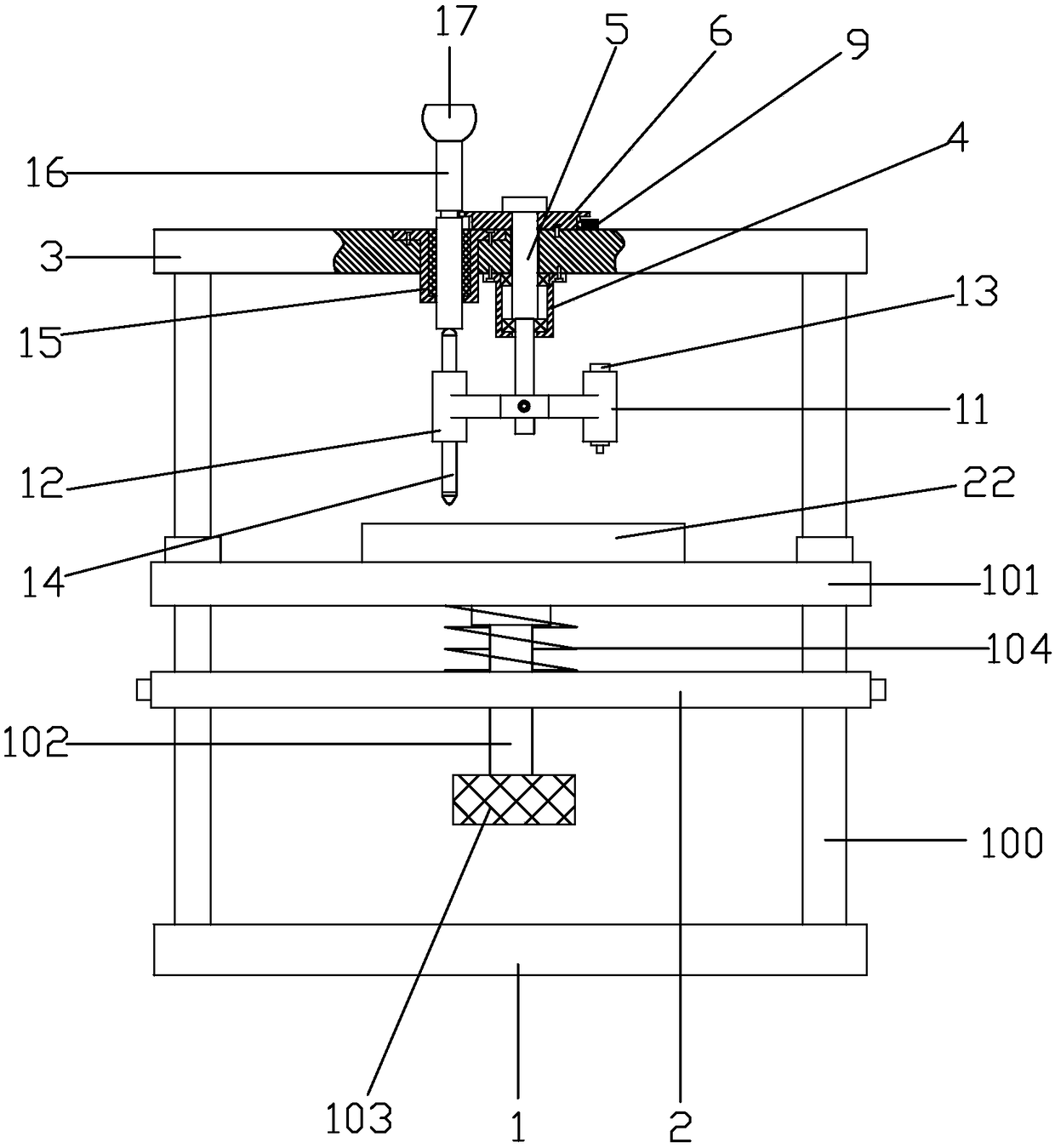

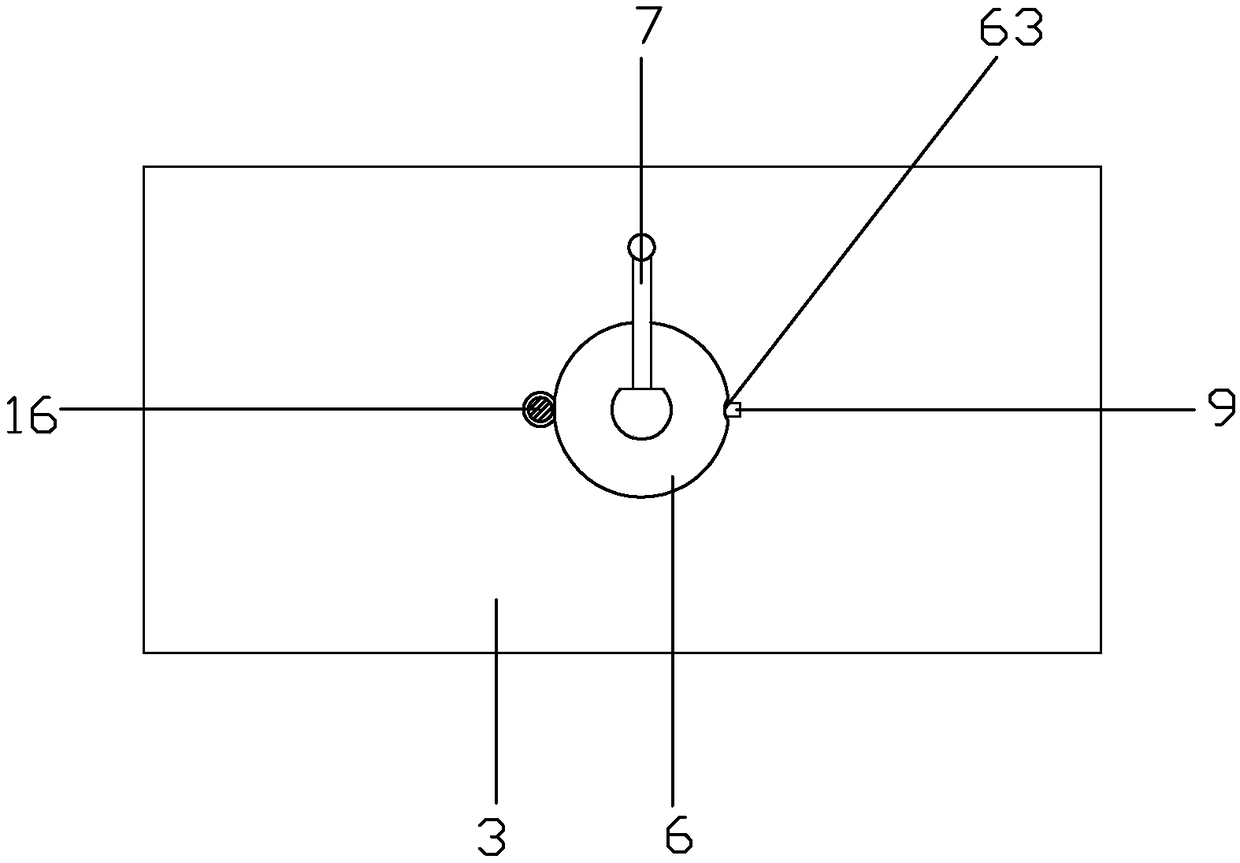

[0026] Such as figure 1 , figure 2 , image 3 and Figure 5 The shown workpiece hole position marking tooling includes a bottom plate 1, vertical support columns 100 are arranged on the four corners of the bottom plate, a base plate 3 is fixed between the upper ends of the support columns, and a support column is fixed at the middle part of the support columns. Plate 2, a lifting plate 101 is provided above the supporting plate, and the lifting plate is slidingly connected with the supporting column. The center of the supporting plate is provided with a vertical screw 102, which is threadedly connected with the supporting plate, and the upper end of the screw is connected to the lifting plate. The bottom surface of the screw rod is rotated and connected, the lower end of the screw rod is provided with a rotating handle 103, and the position betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com