Automatic wall board production device and method

A technology for production equipment and wall panels, which is applied in the field of automatic production equipment for wall panels, can solve the problems of unfavorable large-scale production, long intubation time, and low production efficiency, so as to save production costs and equipment investment, reduce equipment requirements, The effect of shortening the production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

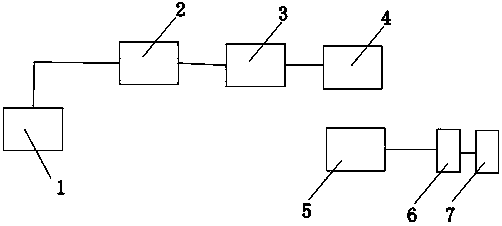

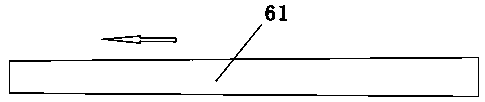

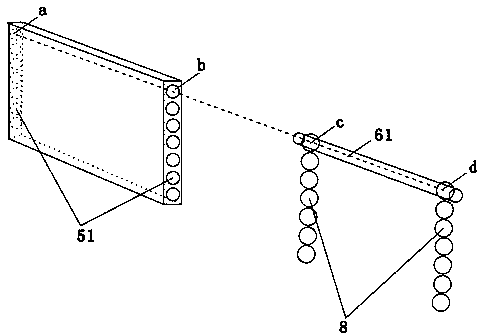

[0021] see figure 1 , a wallboard automatic production equipment, including a feeding unit 1, a metering unit 2, a mixing unit 3, a feeding unit 4, a mold unit 5, a core tube unit 6 and a core tube plugging unit 7, the feeding unit of this embodiment The unit 1 is a screw pump, the metering unit 2 includes a powder metering tank and a water metering tank, the mixing unit 3 is a mixing tank, and a powder storage tank and a water tank are arranged, the feeding unit 1 is connected with the metering unit 2, and the The metering unit is also connected to the mixing unit, and the bottom of the mixing unit is provided with a discharge port, and the mold unit is located below the discharge port. The core tubes 61 of the core tube unit 6 in this embodiment are ten columns and seven rows, that is, ten rows and seven rows can be produced at one time. Each wallboard has seven core holes, and the longitudinal section of the core tube 61 is trapezoidal, such as figure 2 as shown, figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com