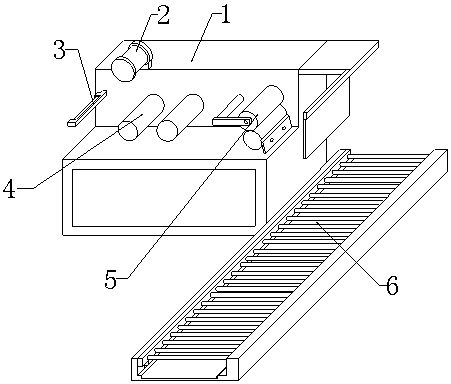

Belt guider for textile production

A guide belt and machine body technology, applied in the direction of conveyors, conveyor objects, conveyor control devices, etc., can solve the problems that the frame cannot be changed automatically, the belt guide machine is inconvenient, and the frame change is not timely, etc., to achieve a simple structure , It is not easy to break the belt, and the effect of reducing the rate of broken belt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

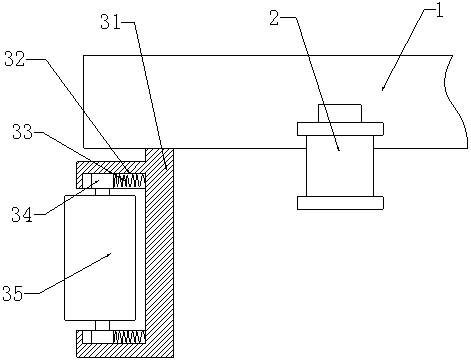

[0024] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS: During the use of the present invention, the textile bypasses the slider 35 and is connected to the guide roller 4 and the conveying roller 5. During the moving process of the textile, a rightward thrust is generated to the slider 35, so that the slider 35 pushes The slider 34 moves inside the chute 32, and the movement of the slider 34 produces pressure on the spring 33, causing the spring 33 to shrink, so that the spring 33 has the elastic force to restore the deformation, thereby moving the slider 35 and the textiles. The textile is not easy to loosen and does not shift, and the design improves the stability of the textile during movement.

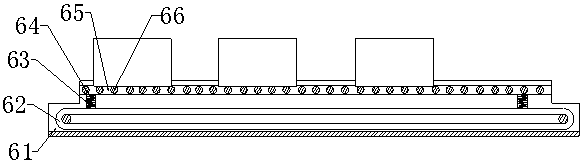

[0025] The textiles are moved to the inside of the frame by the conveying roller 5, and as the number of textiles inside the frame increases, the weight increases, so that the frame exerts pressure on the conveying roller 66, and the conveying roller 66 drives the carriage 65 to m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com