Shock-absorbing device for drying sludge treatment equipment

A technology of shock absorbing device and processing equipment, which is applied in dehydration/drying/thickened sludge treatment, non-rotational vibration suppression, etc., and can solve problems such as stiff shock absorbing process, weak shock absorbing and damping effect, and single shock absorbing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

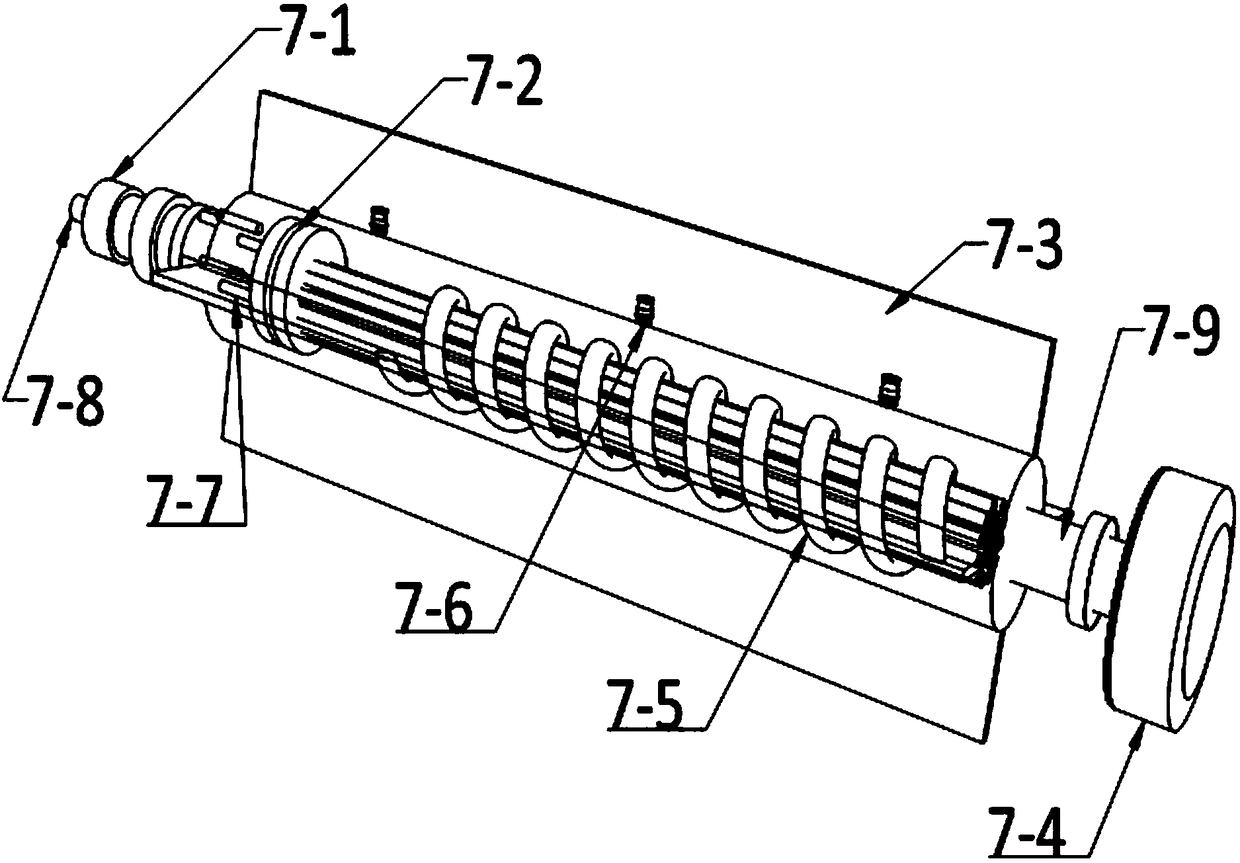

[0072] Prepare the damping device flange 3-9-7-2 of the present invention according to the following steps, and count in parts by weight:

[0073] Step 1: In the stirred vertical tower reactor, add 339.2 parts of purified lake water and N-methyl-1,1,2,2,3,3,4,4,5,5,5-undecafluoro - 131.5 parts of 1-pentanesulfonamide, start the stirrer in the stirring vertical tower reactor, set the speed at 132rpm, start the steam type oil heater in the stirring vertical tower reactor, raise the temperature to 147.2°C, add 134.2 parts of 1-(methoxymethyl)-4-methylbenzene were stirred evenly, and the reaction was carried out for 124.5 minutes. 3 / min of helium for 124.5 minutes; then add 133.1 parts of rutile to the stirred vertical tower reactor, start the steam oil heater in the stirred vertical tower reactor again, raise the temperature to 164.2°C, keep it warm for 124.4 minutes, add 136.9 parts of polymers of 4,4'-(1-methylethylene)bis[2-(2-propenyl)]phenol and (chloromethyl)oxirane, adju...

Embodiment 2

[0076] Prepare the damping device flange 3-9-7-2 of the present invention according to the following steps, and count in parts by weight:

[0077] Step 1: In the stirred vertical tower reactor, add 564.8 parts of purified lake water and N-methyl-1,1,2,2,3,3,4,4,5,5,5-undecafluoro - 173.6 parts of 1-pentanesulfonamide, start the stirrer in the stirring vertical tower reactor, set the speed at 178rpm, start the steam type oil heater in the stirring vertical tower reactor, raise the temperature to 148.8°C, add 243.1 parts of 1-(methoxymethyl)-4-methylbenzene were stirred evenly, and the reaction was carried out for 135.6 minutes. 3 / min of helium for 135.6 minutes; then add 190.3 parts of rutile to the stirred vertical tower reactor, start the steam type oil heater in the stirred vertical tower reactor again, raise the temperature to 197.1°C, keep it warm for 135.4 minutes, add 197.5 parts of polymers of 4,4'-(1-methylethylene)bis[2-(2-propenyl)]phenol and (chloromethyl)oxirane,...

Embodiment 3

[0080] Prepare the damping device flange 3-9-7-2 of the present invention according to the following steps, and count in parts by weight:

[0081] Step 1: In the stirred vertical tower reactor, add 339.9 parts of purified lake water and N-methyl-1,1,2,2,3,3,4,4,5,5,5-undecafluoro - 131.9 parts of 1-pentanesulfonamide, start the stirrer in the stirring vertical tower reactor, set the speed at 132rpm, start the steam type oil heater in the stirring vertical tower reactor, raise the temperature to 147.9°C, add 134.9 parts of 1-(methoxymethyl)-4-methylbenzene were stirred evenly, and reacted for 124.9 minutes. minutes; then add 133.9 parts of rutile into the stirred vertical tower reactor, start the steam oil heater in the stirred vertical tower reactor again, raise the temperature to 164.9°C, keep the temperature for 124.9 minutes, add 4,4'-( 136.9 parts of polymers of 1-methylethylene) two [2-(2-propenyl)] phenol and (chloromethyl) oxirane, adjust the pH value of the solution i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com