Leather roller with monitoring function and for drafting mechanism of spinning machine

A spinning machine and functional technology, applied in the field of top rollers with monitoring function for the drafting mechanism of the spinning machine, to achieve the effects of avoiding erosion, convenient and fast use, loading and unloading maintenance, and convenient replacement and loading and unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

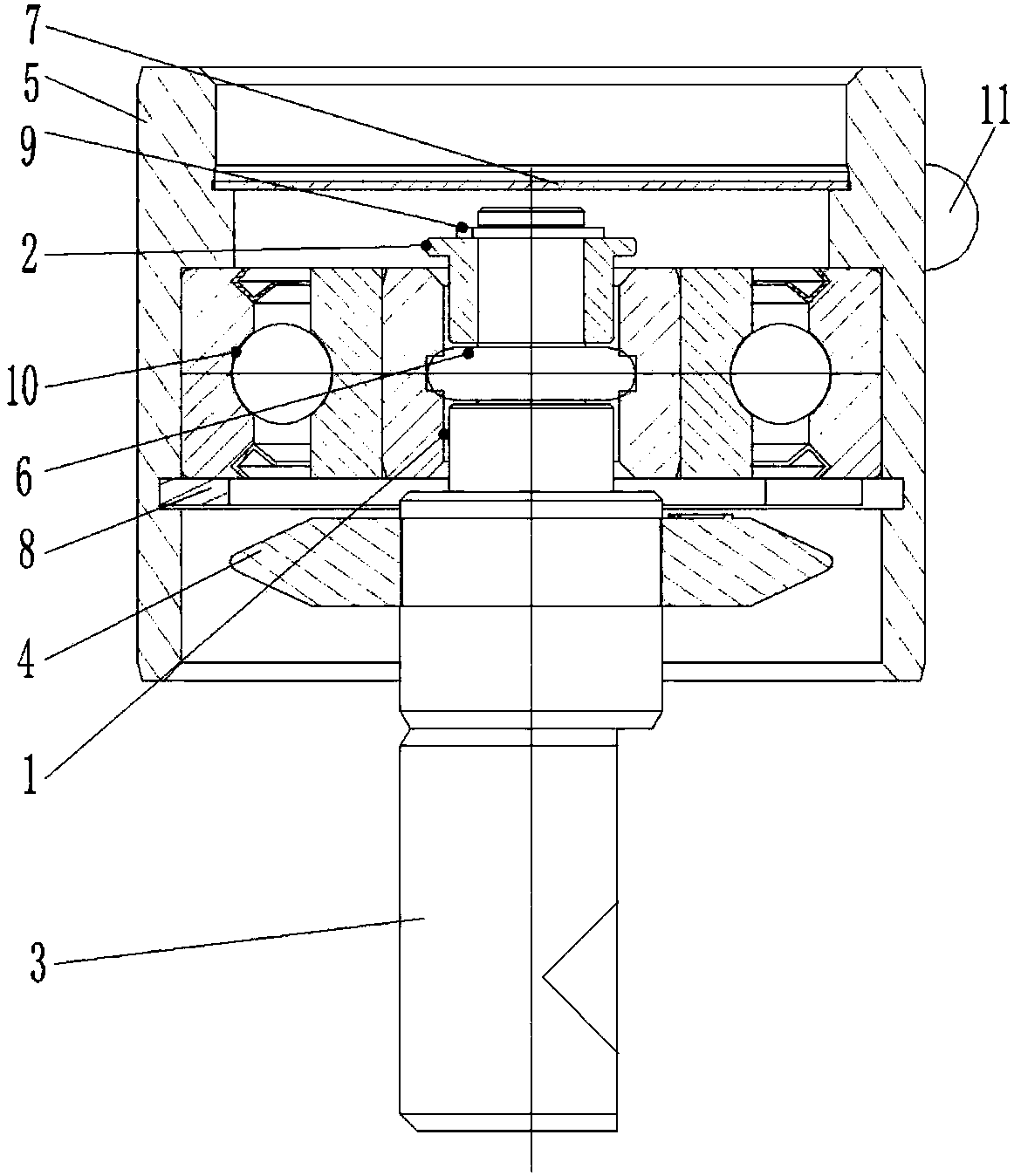

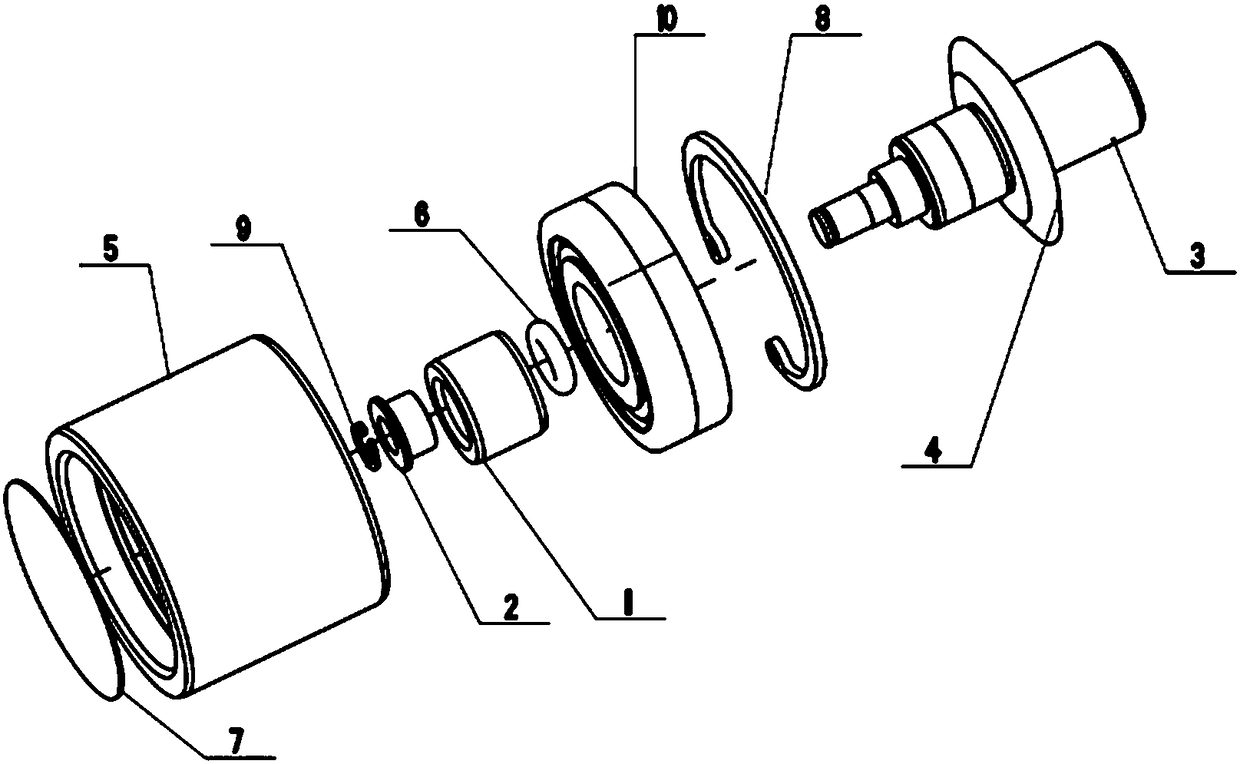

[0027] Such as Figure 1-Figure 2 As shown, a top roller with a monitoring function for the drafting mechanism of a spinning machine in this embodiment includes a bearing inner sleeve 1, a shaft sleeve 2, a shaft 3, a nylon ring 4, an outer sleeve 5, a rubber ring 6, a dustproof Cover 7 , first retaining ring 8 , second retaining ring 9 , bearing 10 and vision sensor 11 .

[0028] The connection relationship of the above-mentioned components is as follows: the shaft 3 passes through the rubber ring 6 and is sequentially connected with the bearing inner sleeve 1 and the shaft sleeve 2, and the end of the shaft 3 is sleeved with a second retaining ring 9, and the second washer 9 offsets the shaft sleeve 2; the middle part of the shaft 3 is covered with a nylon ring 4, and the lower part of the shaft sleeve 2 is nested inside the bearing inner sleeve 1; the bearing inner sleeve 1 is integrally nested inside the bearing 10, and the The bearing 10 is nested inside the outer casing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com