Concrete slab partition wall structure

A technology of concrete slabs and aerated concrete slabs, applied in walls, building components, building structures, etc., can solve problems such as easy cracking, and achieve the effect of sound insulation and breathing performance safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

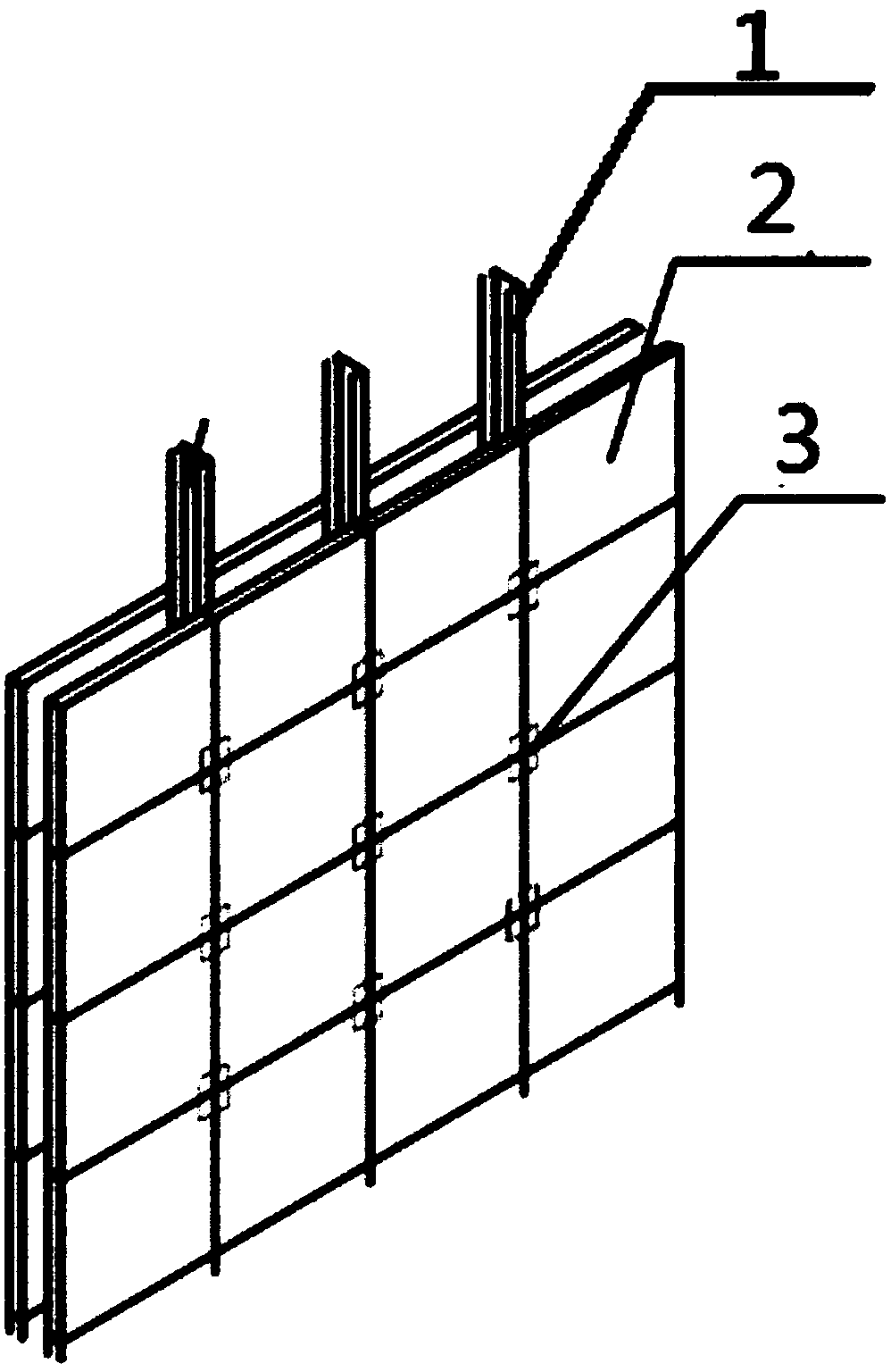

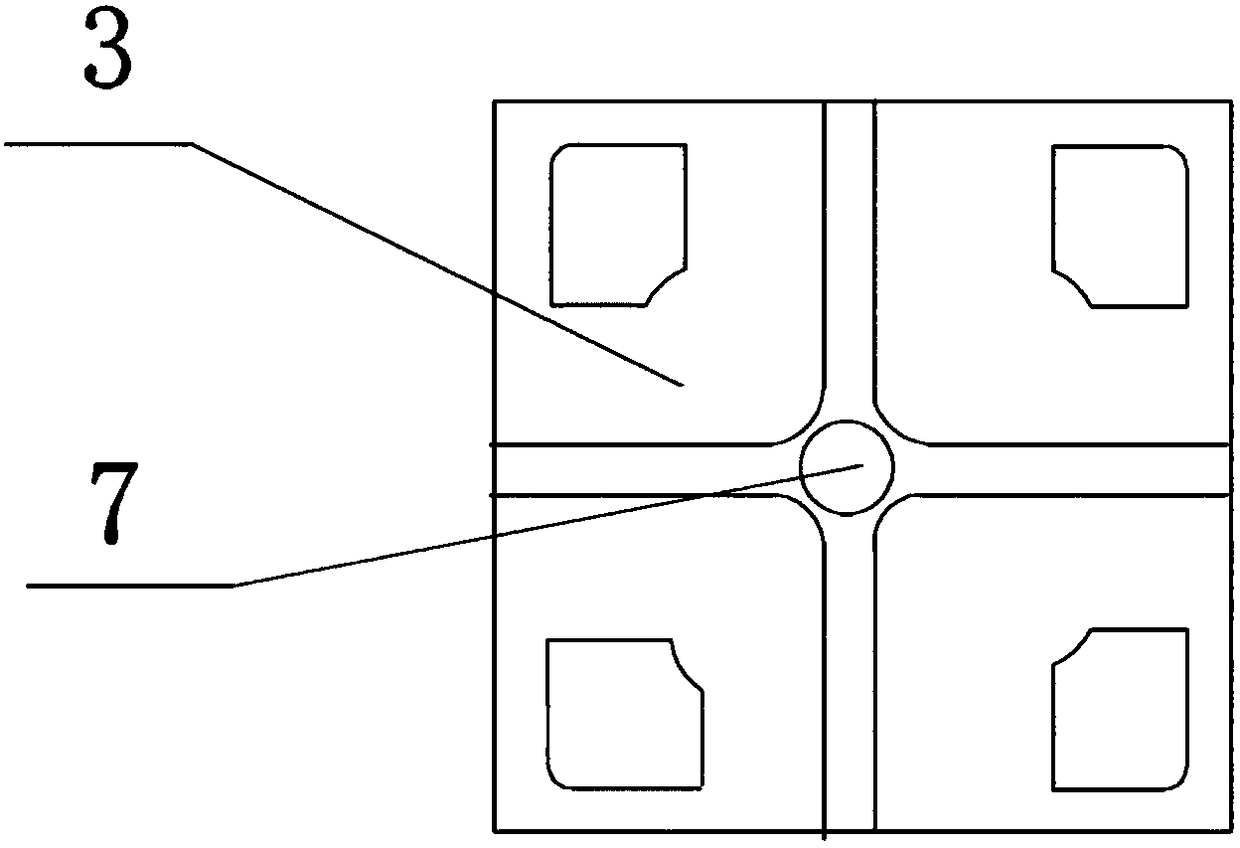

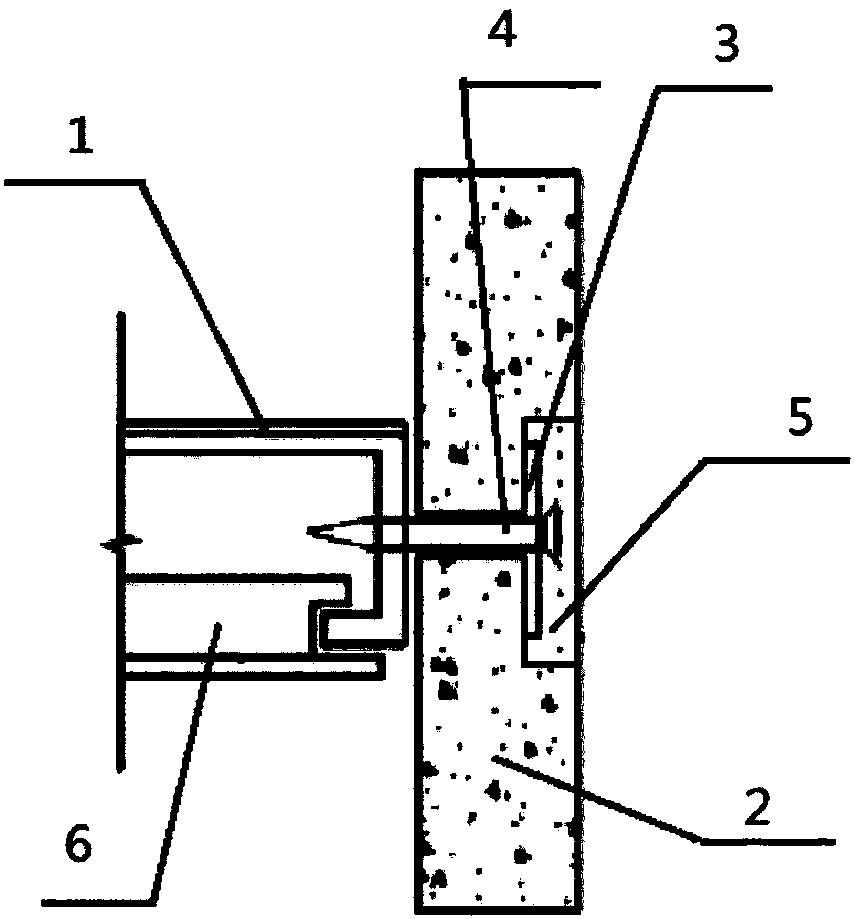

[0022] A light steel keel autoclaved sand aerated concrete slab partition wall structure, including a light steel keel 1 and several autoclaved sand aerated concrete slabs 2, a plurality of longitudinally parallel light steel keels 1 as wall core keel supports, autoclaved The sand aerated concrete slab 2 is pasted and hung on both sides of the core keel bracket of the wall. The light steel keel 1 is cold-formed inner-rolled channel steel, which is made of high-quality cold-rolled continuous hot-dip galvanized coil as raw material and produced by cold-bending process Thin-walled section steel, double-sided galvanized quantity ≥ 120g / m2, thickness 0.5mm ~ 1.5mm, light steel keel 1 has installation holes on both side walls, and support clips 6 between the two side walls, light steel keel 1 The two side walls are facing the joint surface of two autoclaved sand aerated concrete slabs 2, the joint surface is bonded by adhesive, and the fullness is over 90%. The size of each autoclave...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com