Magnetic connecting shaft type hand cranking small-flow LNG filling pump

A small flow, filling pump technology, applied in the direction of rotary piston pump, rotary piston type/swing piston type pump parts, pumps, etc. Ease of use and improved slip resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

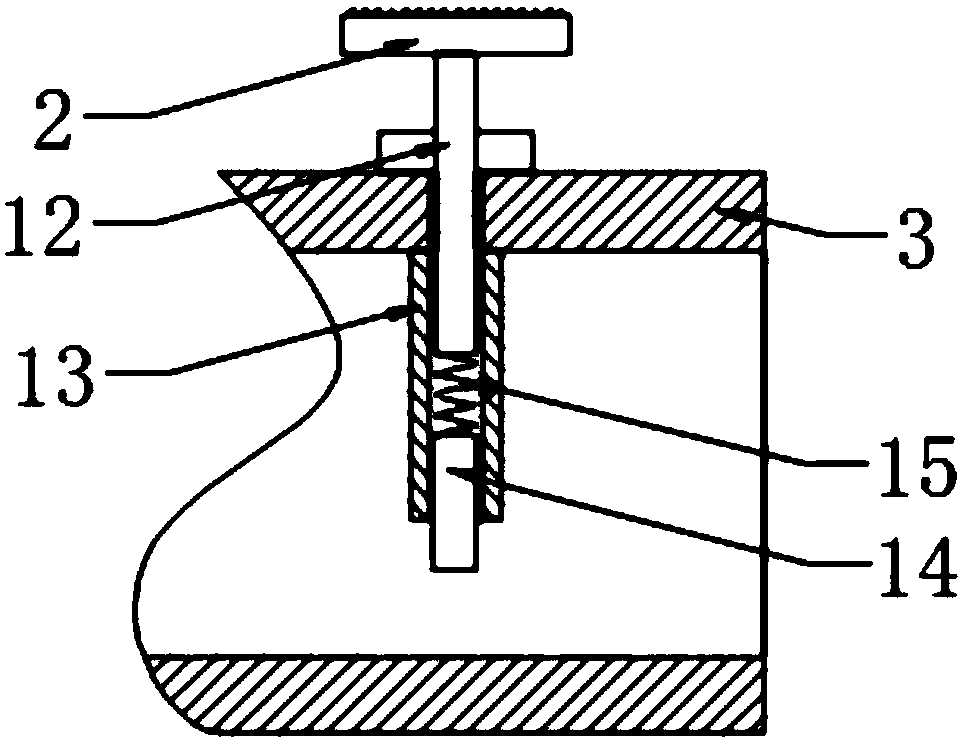

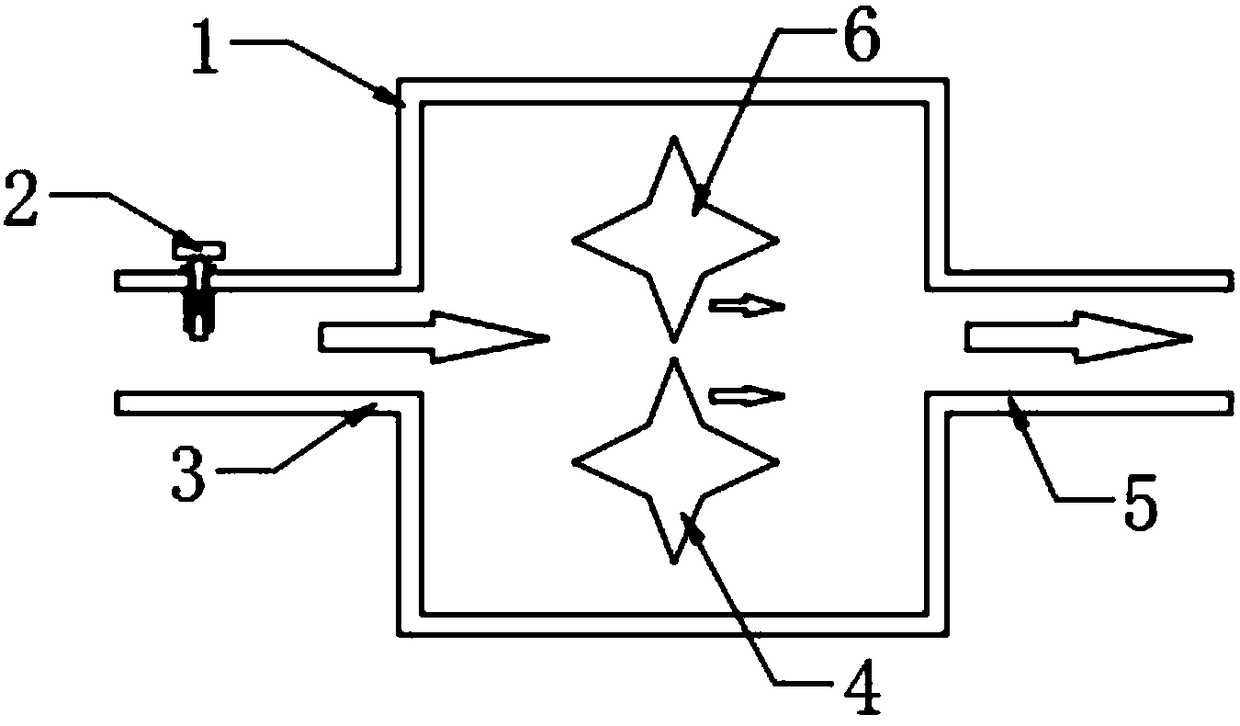

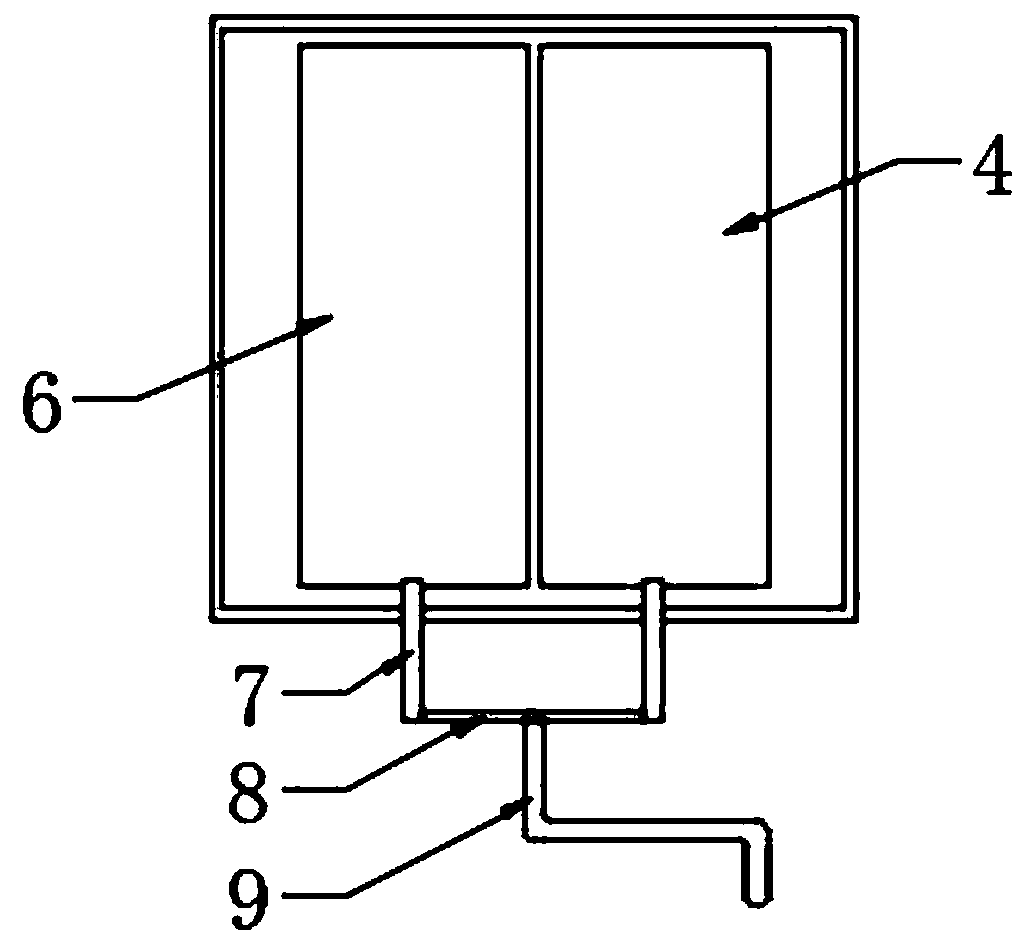

[0022] see Figure 1-Figure 4 , the present invention provides a technical solution: a magnetic coupling type manual low-flow LNG filling pump, including a pump body 1, a liquid inlet 3 and a liquid discharge port 5, and a liquid inlet 3 is installed on the left end of the pump body 1 The right end of the pump body 1 is equipped with a drain port 5, the inner rear of the pump body 1 is equipped with a driving impeller 2 6, the inner front of the pump body 1 is equipped with a driving impeller 1 4, and the lower end of the pump body 1 is equipped with a magnetic coupling 7. A driving force transmission system 8 is installed in the middle of the magnetic coupling 7, a hand crank 9 is installed in the middle of the lower end of the driving force tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com