Driving-free energy saving bulb

An energy-saving light bulb, driver-free technology, applied in lampshades, lighting and heating equipment, semiconductor devices of light-emitting elements, etc., can solve the problems of heavy connection of driving power supply and inability to perform actual operations, and achieves reduction in the amount of electronic waste generated and the design of And the effect of convenient and flexible use and improved design concept

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

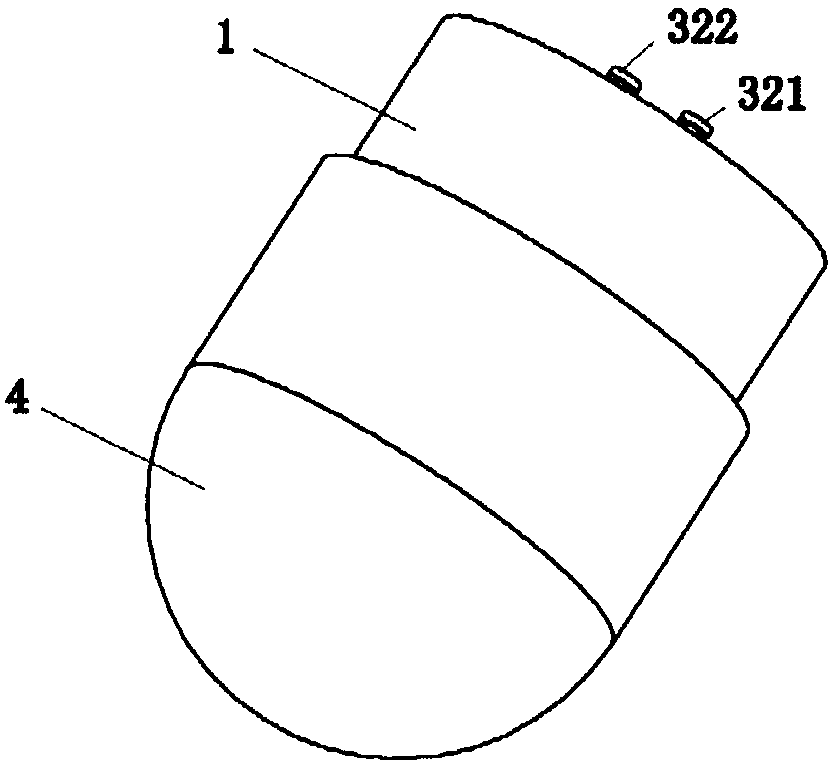

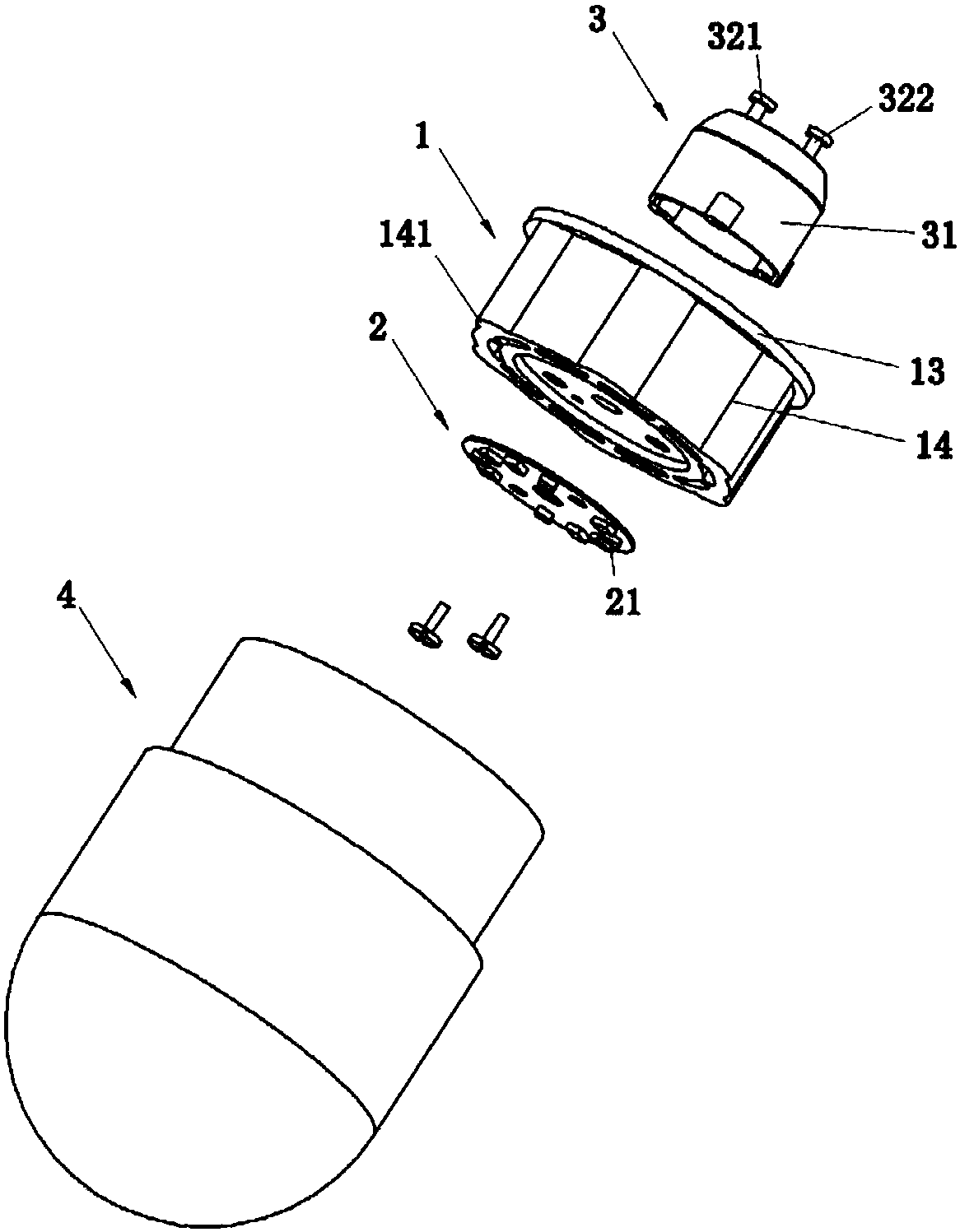

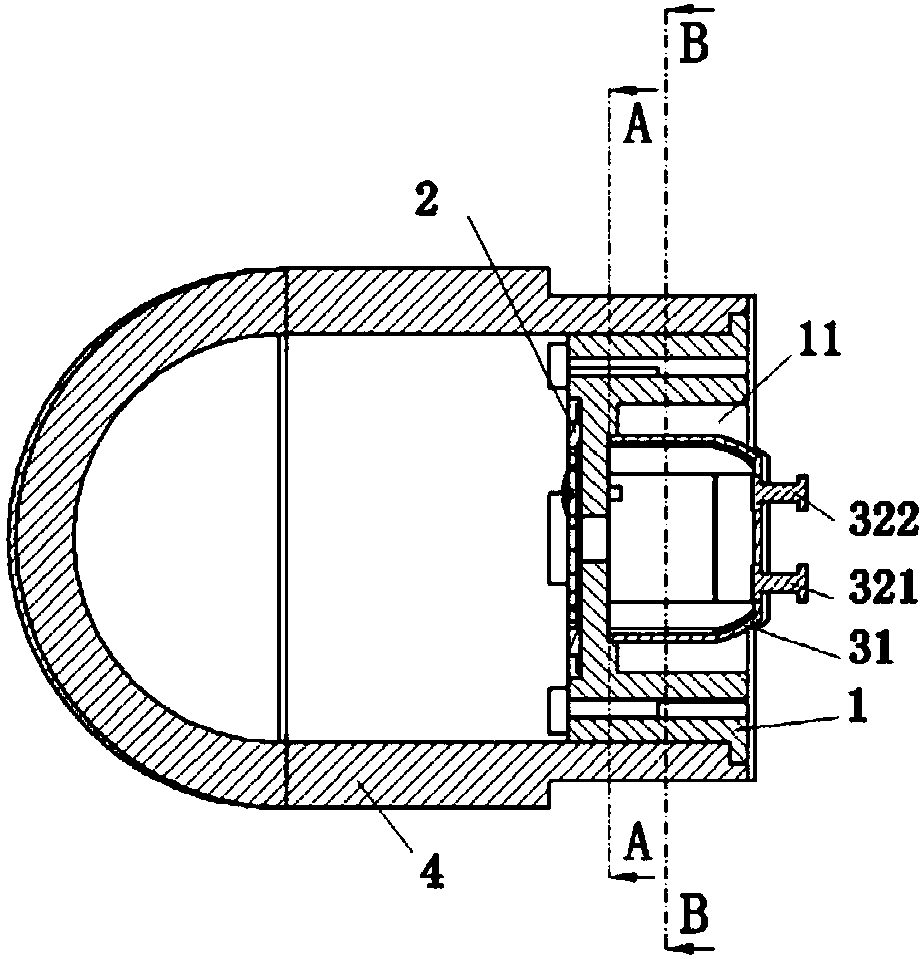

[0020] as attached figure 1 to attach Figure 5 As shown, the driver-free energy-saving light bulb includes a radiator 1, a circuit module and an LED lamp board 2, the LED lamp board 2 is installed on the radiator 1, and the circuit module includes a varistor installed on the LED lamp board 2 and electrically connected in sequence, A bridge rectifier, a chip resistor and an LED module. The LED module includes several light-emitting chips 21 and is connected in parallel. By sequentially electrically connecting the varistor, the bridge rectifier, the chip resistor and the LED module, the circuit module can be The mains power is converted into a voltage and current suitable for the LED chip to emit light, so that the LED chip 21 can normally emit light.

[0021] The radiator 1 is provided with a lamp cap assembly 3 for electrically connecting the circuit module with the mains. The lamp cap assembly 3 includes a lamp cap shell 31 and a first connecting piece 321 and a second con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com