Light source structure wide in light outgoing face

A light-emitting surface and light source technology, applied in the field of LED lighting, can solve the problems of rigid and single structural design, glare, lack of novelty, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

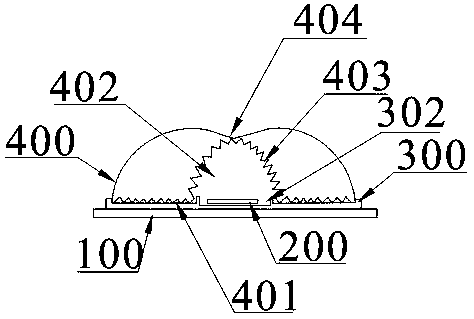

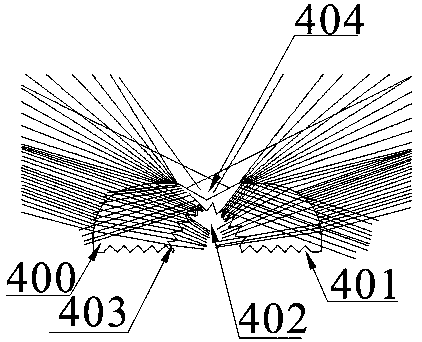

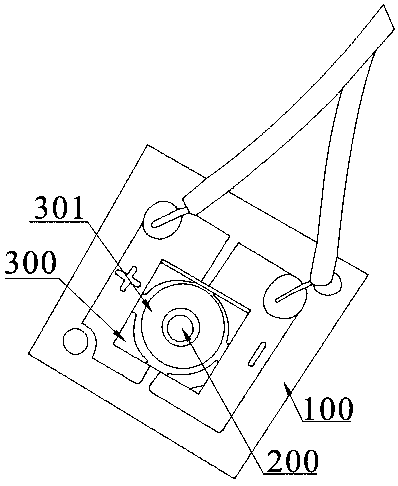

[0021] refer to Figure 1 to Figure 3 , an embodiment of a light source structure with a wide light-emitting surface of the present invention is proposed, which can be installed on a lamp for large-angle lighting, including a substrate 100, an LED chip 200 disposed on the substrate 100, and a fluorescent light covering the LED chip 200. Layer, the LED chip 200 is fixed on the substrate 100 through a bracket 300, and the bracket 300 is made of insulating material, which has good insulation performance and high safety performance. The bracket 300 is provided with a light source cavity 302 for accommodating the LED chip 200, and the LED chip 200 is encapsulated in the light source cavity 302 through a fluorescent layer. In this embodiment, the conductive pins led out from the LED chip 200 pass through the bracket 300 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com