Temperature control circuit of variable frequency heat pump driver

A temperature control and drive technology, applied in household heating, heating methods, household heating, etc., can solve problems such as discontinuous working process, alarm shutdown, poor user experience, etc., to meet safe operation, improve the life of the whole machine, The effect of reducing the failure rate of the whole machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the technical purpose, technical solution and technical effect of the present invention clearer so that those skilled in the art can understand and implement the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

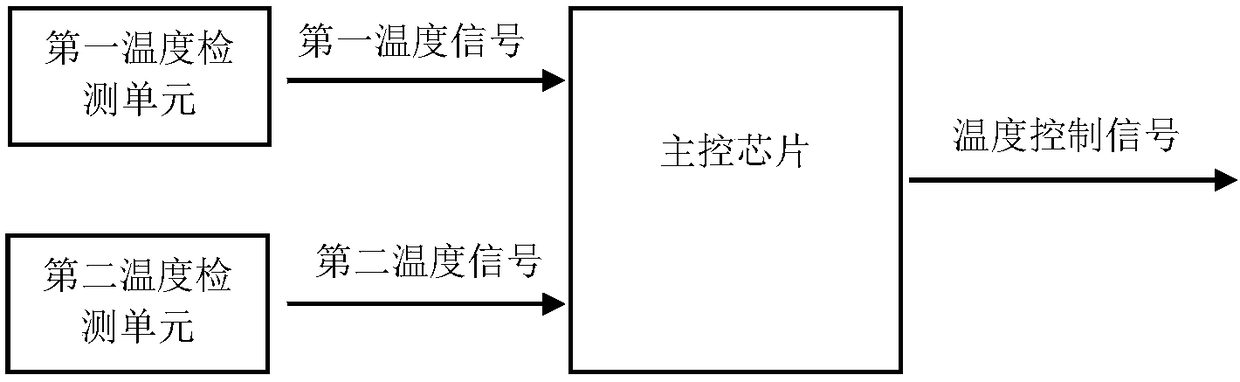

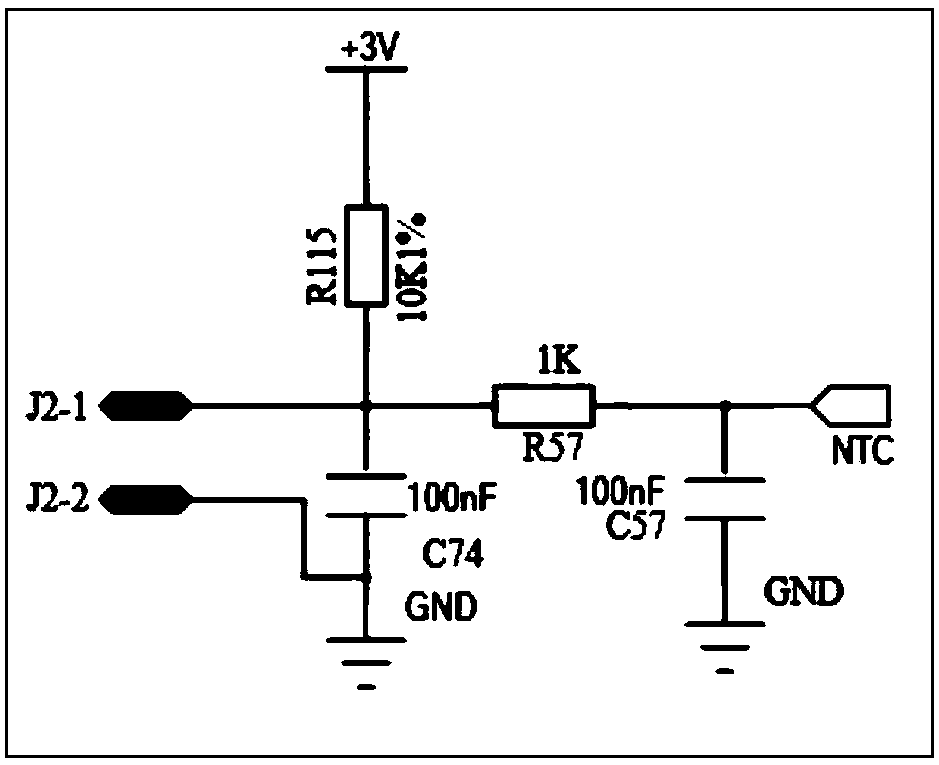

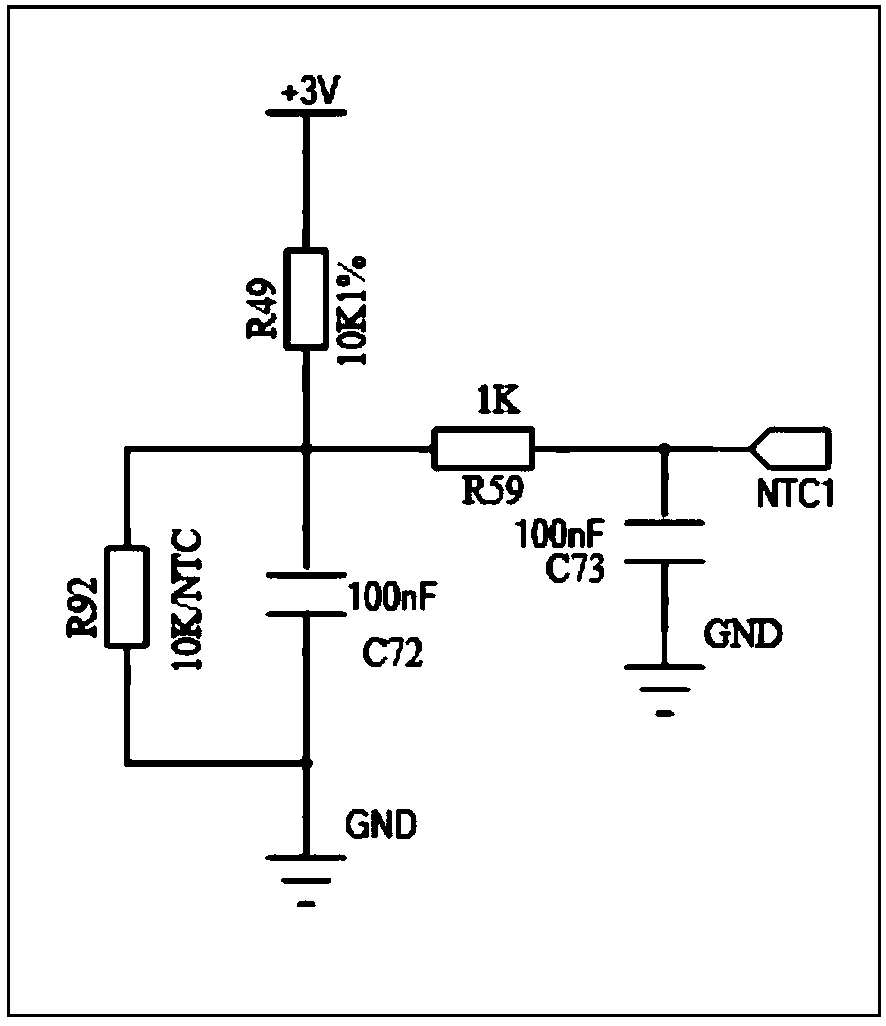

[0033] Such as figure 1 as shown, figure 1 A schematic diagram of the functional modules of the temperature control circuit of the variable frequency heat pump driver according to the embodiment of the present invention is shown. The variable frequency heat pump driver temperature control circuit is used to control the output of the variable frequency heat pump driver device at high temperature, the variable frequency heat pump driver includes an inverter bridge circuit, a rectifier bridge circuit, a power factor correction circuit and a temperature control circuit; the temperature control circuit includes The first temperature detection u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com