Glass box liquid crystal filling opening sealing mechanism of full-automatic leveling and sealing machine for liquid crystal glass boxes

A fully automatic, pouring port technology, applied in nonlinear optics, instruments, optics, etc., can solve the problem of high scrap rate, achieve high automation, save manpower and material resources, and avoid liquid crystal pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

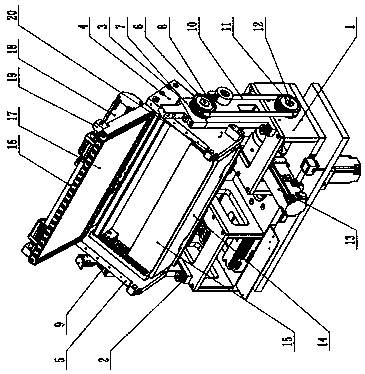

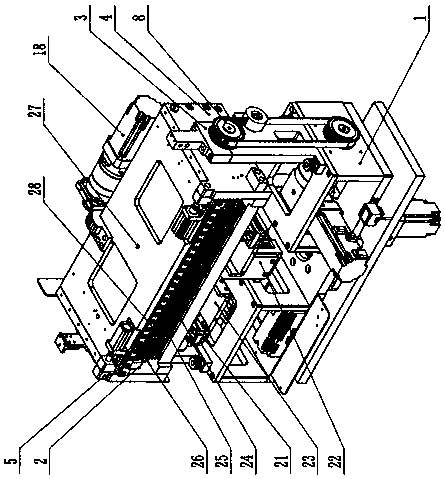

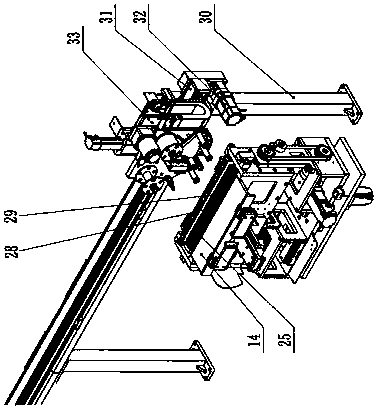

[0020] The present invention is described in detail below in conjunction with accompanying drawing:

[0021]A fully automatic leveling and sealing machine for liquid crystal glass boxes, including a leveling seat box mechanism and a glass box liquid crystal filling port sealing mechanism, the leveling seat box is arranged on the seat box base 1, and can rotate at a certain angle under the control of a servo motor , the seat box base 1 of the leveling seat box mechanism is respectively provided with a left column 2 and a right column 3, and a right support shaft 6 is fixedly arranged on the seat box right side panel 4 of the leveling seat box, The left support shaft is fixedly arranged on the left side panel 5 of the seat box, the right support shaft bearing 7 is arranged on the top of the right column 3, the left support shaft bearing 9 is arranged on the top of the left column 2, and the right support shaft 6 is arranged on the right support shaft. In the shaft bearing 7, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com