Cloud control hanging system based on Internet of Things technology

An Internet of Things technology and cloud control technology, applied in the field of big data industrialization, can solve the problems of automation of production lines, low degree of informatization, difficulty in real-time monitoring and control of production processes, low efficiency of internal production logistics, etc., to improve logistics management and efficiency. The effect of handling efficiency, reducing labor participation rate, and improving data accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

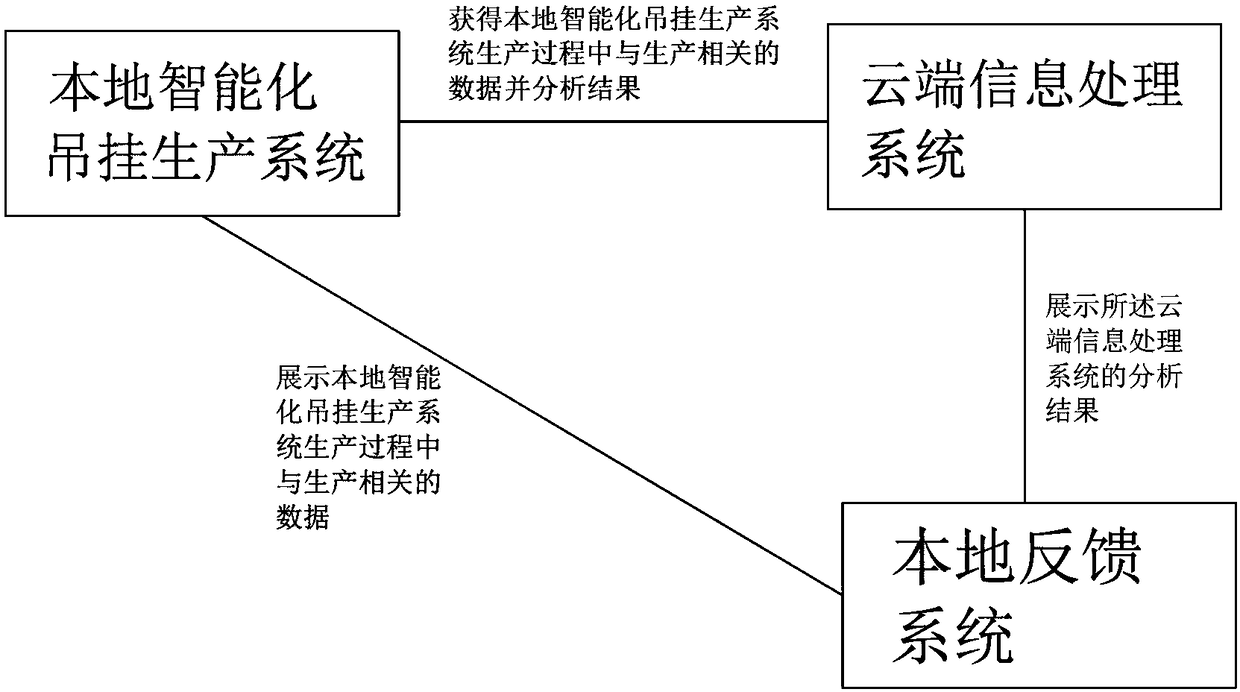

[0055] Example 1, such as figure 1 , 3 , 5, a cloud-controlled hanging system based on Internet of Things technology, including a local intelligent hanging production system, a cloud information processing system and a local feedback system, the three systems communicate with each other, and the cloud information processing system has huge data storage Space and powerful big data computing capabilities, real-time reception of production-related data collected by the local intelligent hanging production system, after calculation and analysis, the analysis results are obtained, and fed back to the local feedback system to act on the local production management system. Scientific guidance and control of each production chain, intensive and unified management, rational allocation of resources, and increased production capacity.

[0056] The local intelligent hanging production system is based on transportation equipment and identification equipment for assisting high-efficiency i...

Embodiment 2

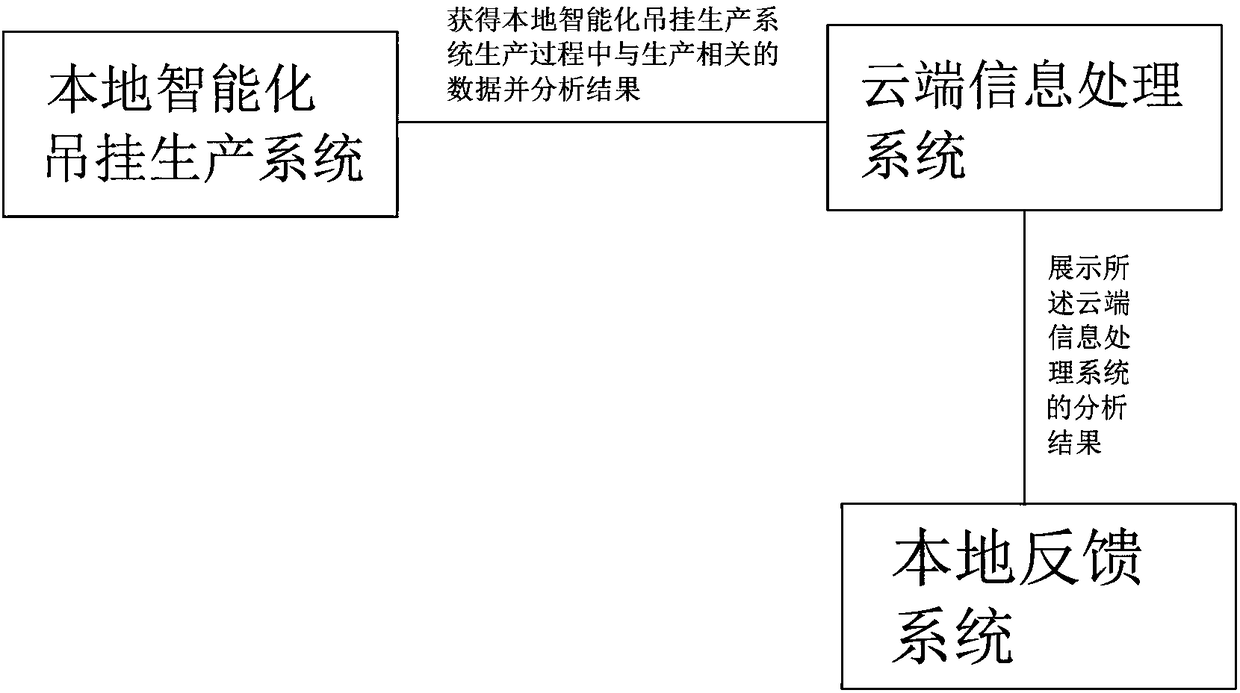

[0075] Example 2, such as figure 2 , 4 , Shown in 5, based on embodiment 1, differs from embodiment 1 in that:

[0076] The cloud information processing system communicates with the local intelligent hanging production system, and is used to obtain production-related data in the production process of the local intelligent hanging production system, analyze the results, and feed back the results to the local Intelligently hang the production system and guide it;

[0077] The local feedback system communicates with the cloud information processing system, and is used to display production-related data in the production process of the local intelligent suspension production system and analysis results of the cloud information processing system.

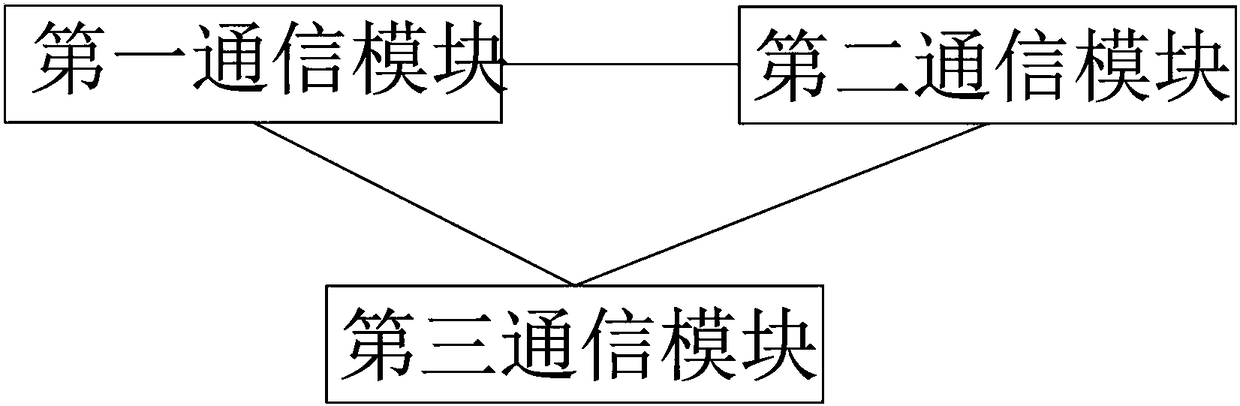

[0078] The third communication module communicates with the second communication module.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com