Electric reactor iron core compressing structure and electric reactor iron core compressing device

A compression structure and compression device technology, applied in the direction of transformer/inductor magnetic core, inductor/transformer/magnet manufacturing, circuits, etc., can solve the problems of poor compression effect, complicated assembly, and increased operating vibration amplitude, etc. Achieve the effect of saving processing costs, reducing safety hazards, and stable pressing force value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments (embodiments). The specific embodiments described here are only used to explain the present invention, but not as a basis for limiting the present invention.

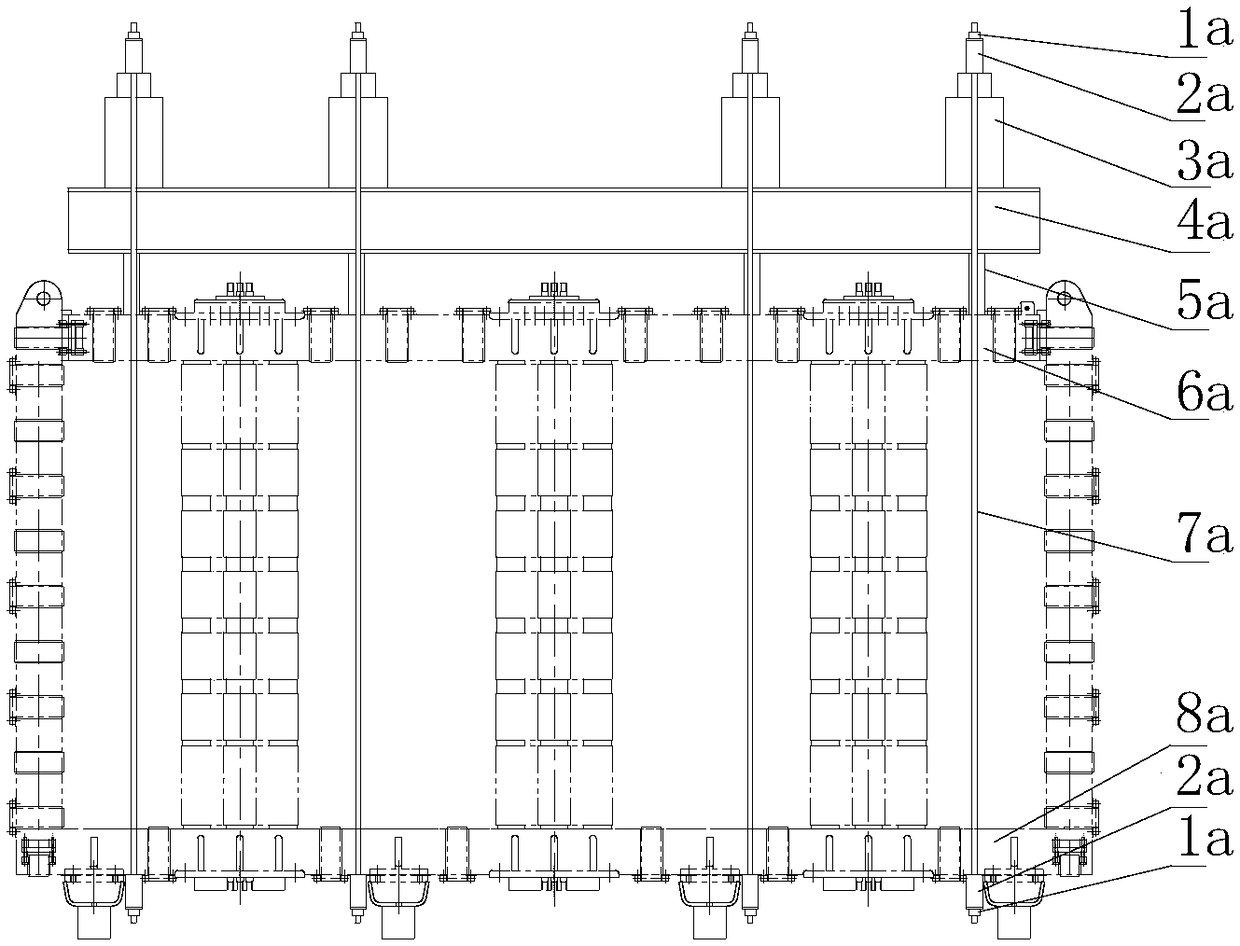

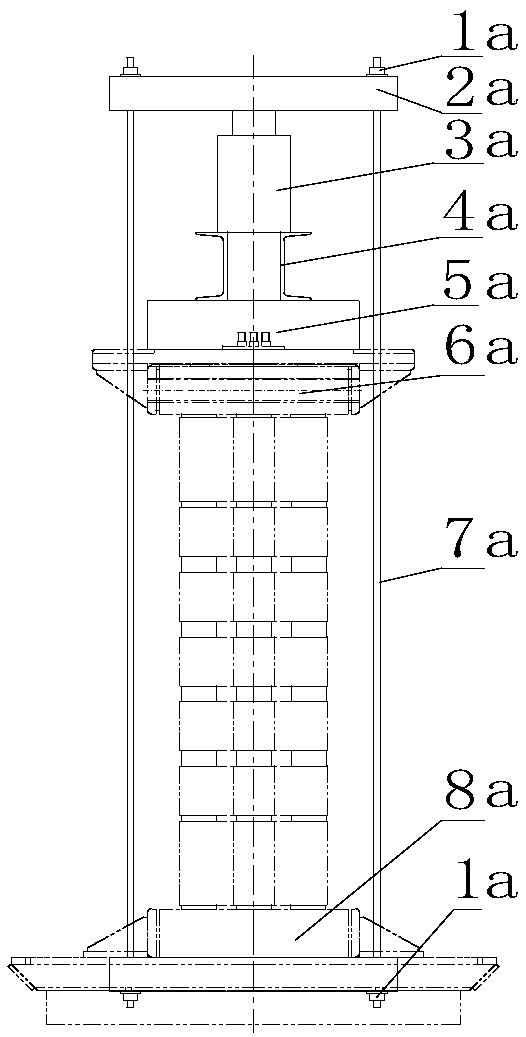

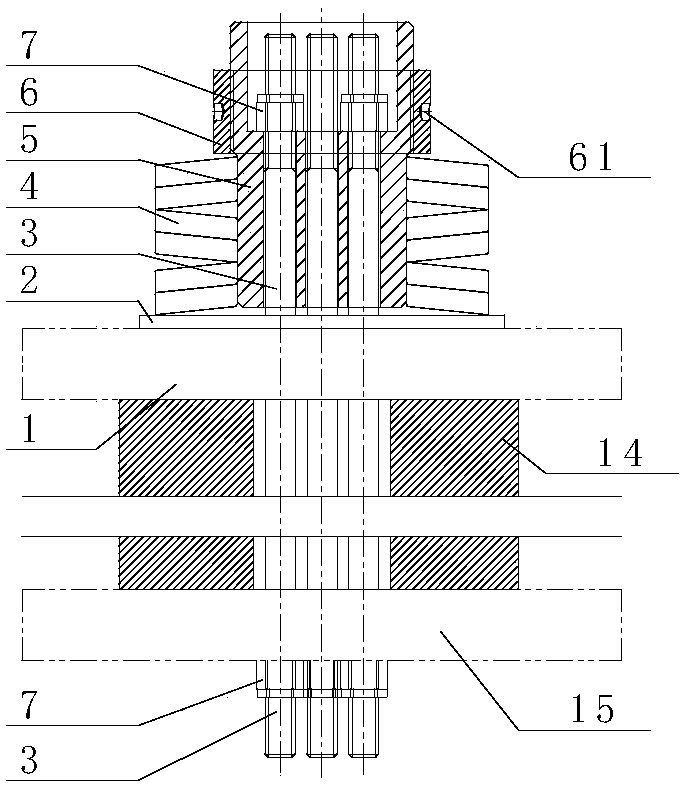

[0036] see image 3 , the reactor iron core compression structure of the present invention includes an iron core 14, an iron core upper joist 1 and an iron core lower joist 15 respectively arranged at the upper and lower ends of the iron core 14, and at least one iron core lower joist 15. The iron core 14 and the core column pull screw 3 of the iron core joist 1; the iron core upper joist 1 is provided with a pull screw sleeve 5, and the upper end of the core column pull screw 3 is pulled from the pull screw sleeve The corresponding holes on the 5 stretch out; the two ends of the stem pull screw 3 are fastened by the pull screw nut 7 respectively; the outer ring of the pull screw sleeve 5 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com