A Coupler Based on Substrate Integrated Gap Waveguide

A gap waveguide and substrate integration technology, applied in the field of electronics, can solve problems such as no public reports, and achieve the effects of easy integration, low profile, and wide bandwidth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The technical solutions of the present invention will be further described in detail below in conjunction with specific embodiments.

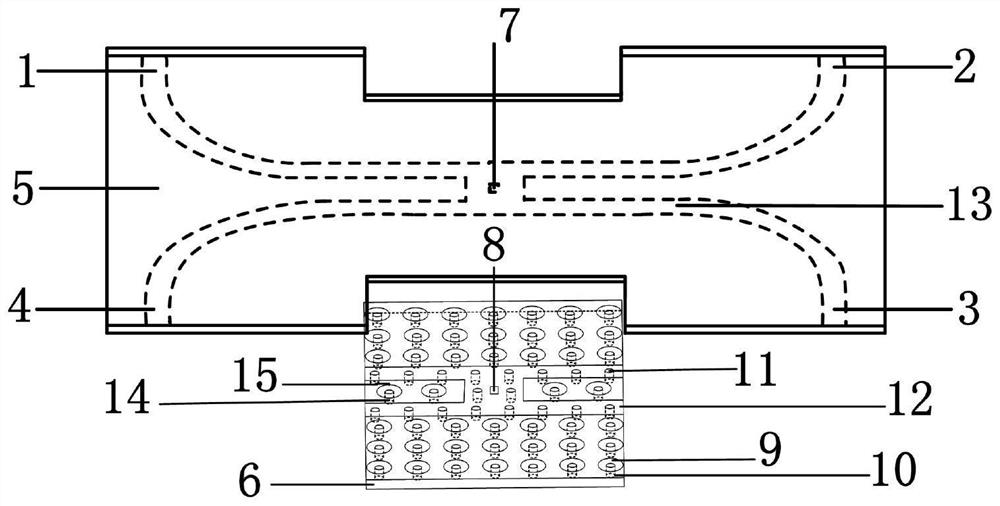

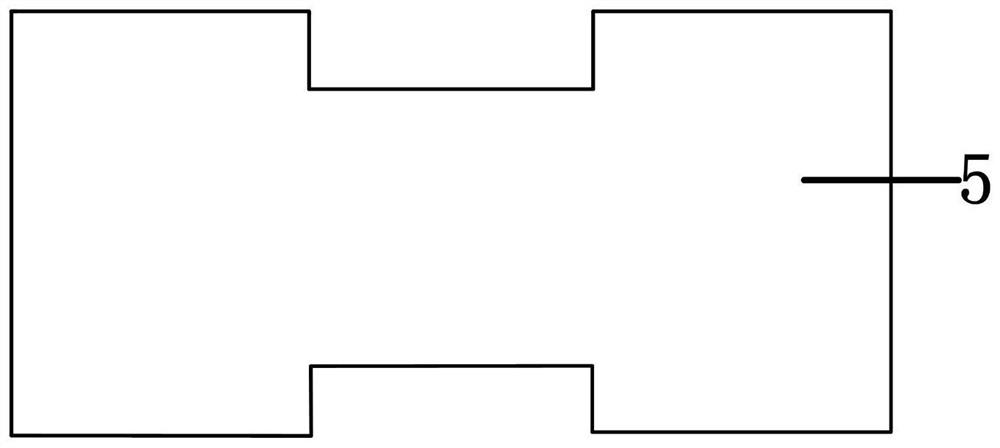

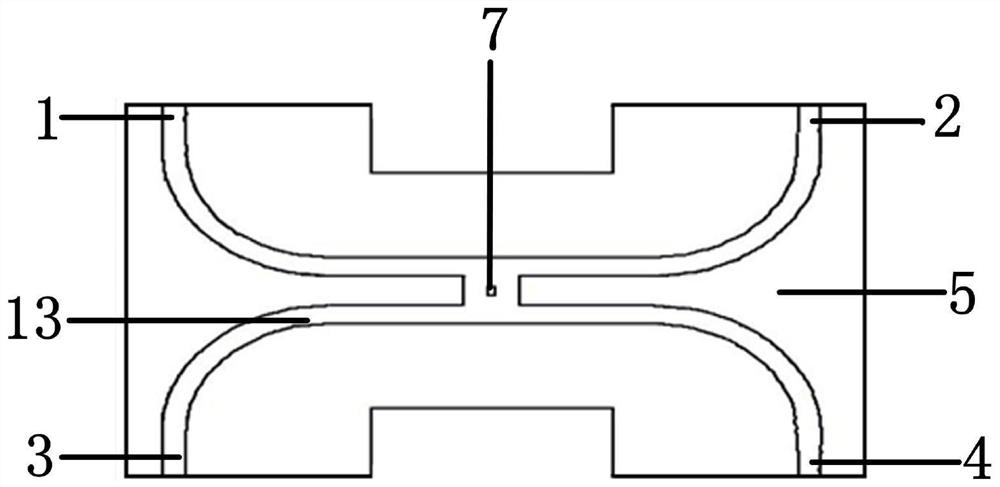

[0036] Such as Figure 1-5 As shown, a coupler based on a substrate-integrated gap waveguide includes: an upper dielectric plate 5 and a lower dielectric plate 6, wherein:

[0037] a. The upper dielectric board 5 is a rectangular dielectric board with two rectangular slots, the upper surface is printed with a metal ground, and the lower surface is printed with a coupling microstrip line 13; the middle position of the coupling microstrip line 13 is provided with a first Rectangular slot 7; the four ports of the coupled microstrip line 13 are respectively the first port 1, the second port 2, the third port 3 and the fourth port 4; the first port 1 is an input port, and the second port 2 is a through port , the third port 3 is a coupling port, and the fourth port 4 is an isolation port;

[0038] b. The lower surface of the lower dielectri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com