Power supply patch board

A technology of power strips and conductive rods, which is applied in the direction of circuits, electrical components, coupling devices, etc., can solve the problems of limited number of row jacks, small row jacks, occupation, etc., and achieve the effect of random disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

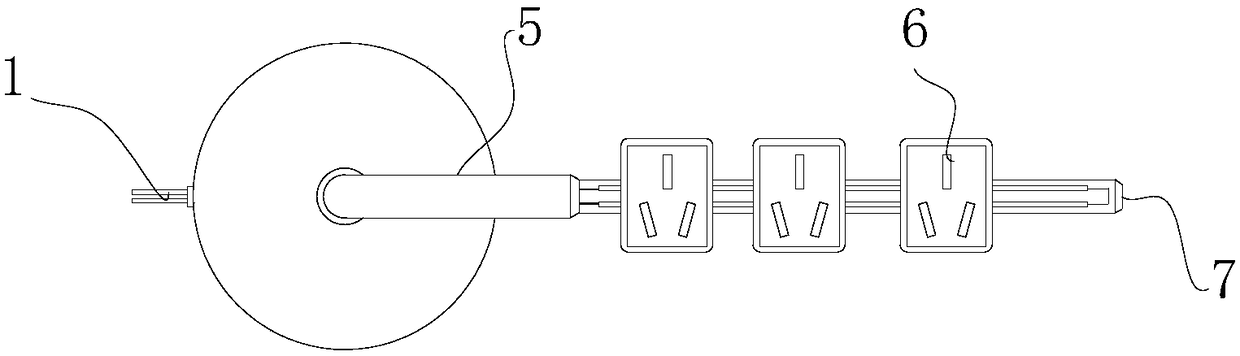

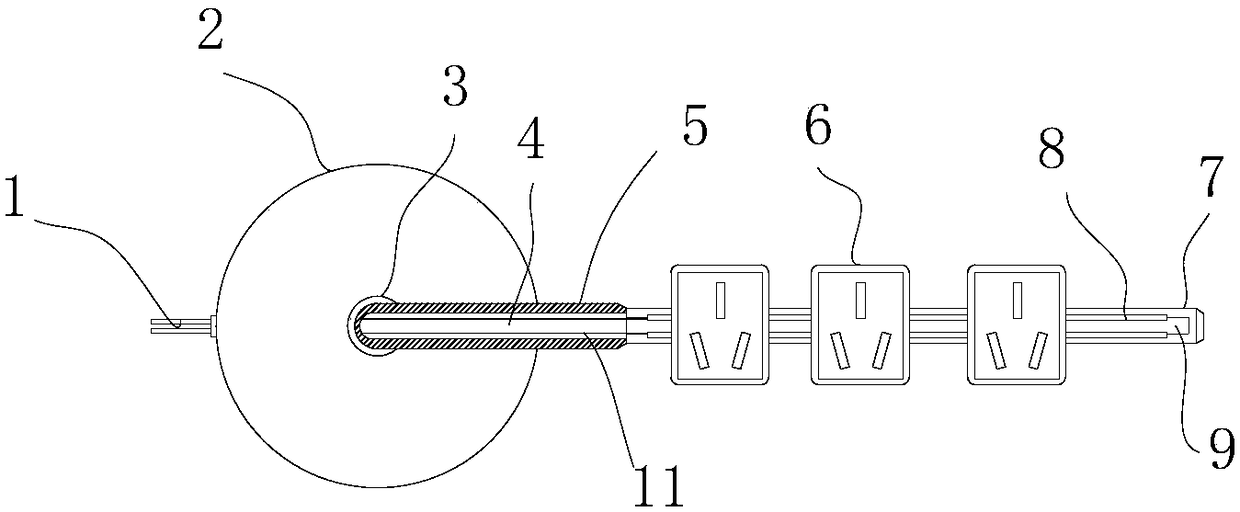

[0015] Such as figure 1 with figure 2 As shown, the power strip includes a base 2, a bearing 3 is embedded in the center of the upper end of the base 2, a connecting shaft 5 is inserted into the bearing hole of the bearing 3, and a bending part (not shown) is arranged at the bottom of the connecting shaft 5 ), the bending part is installed in the bearing hole of the bearing, a conductive rod 7 is fixedly arranged on the outer end of the connecting shaft 5, a conductive cavity 9 is formed in the middle of the conductive rod 7, and a conductive copper row is embedded on both sides of the inner wall of the conductive cavity 9 8. One end of the conductive copper bar 8 protrudes from the outer surface of the conductive chamber 9 , and more than one socket module 6 is detachably installed on the upper end surface of the conductive rod 7 .

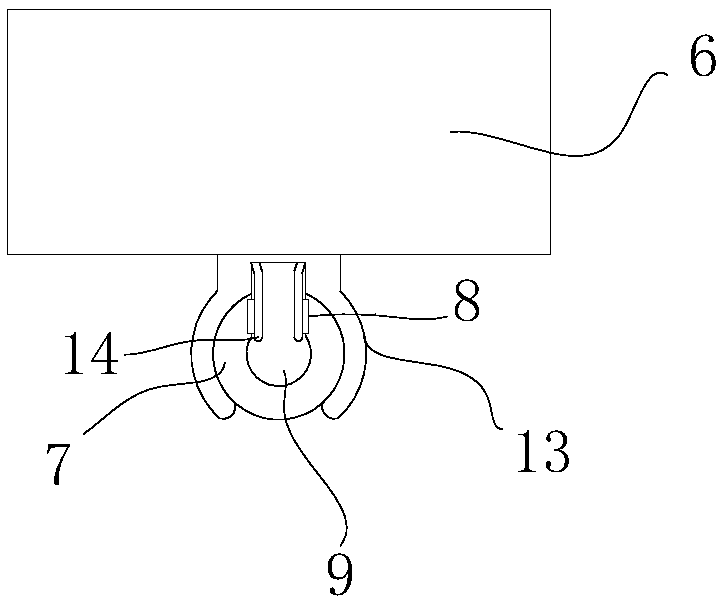

[0016] Among them, such as image 3 As shown, the lower end surface of the socket module 6 is provided with an arc-shaped connecting sleeve 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com