Cable processing system and power line assembling system

A technology for processing systems and cables, applied in circuit/collector parts, circuits, electrical components, etc., can solve the problems of poor consistency, low efficiency, and high defect rate, and achieve good consistency, high efficiency, and low defect rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] see figure 1 , this embodiment provides a cable processing system, the cable to be processed includes a sheath 1a and at least one core wire 2a, the sheath 1a is sheathed outside the at least one core wire 2a, the cable processing system can make the wire The sheath 1a of the cable and the sheath 3a of the core wire 2a are stripped to a set length.

[0065] see Figure 27 , it should be noted that, in this embodiment, the description will be made by taking the cable wrapped with three core wires 2a as an example.

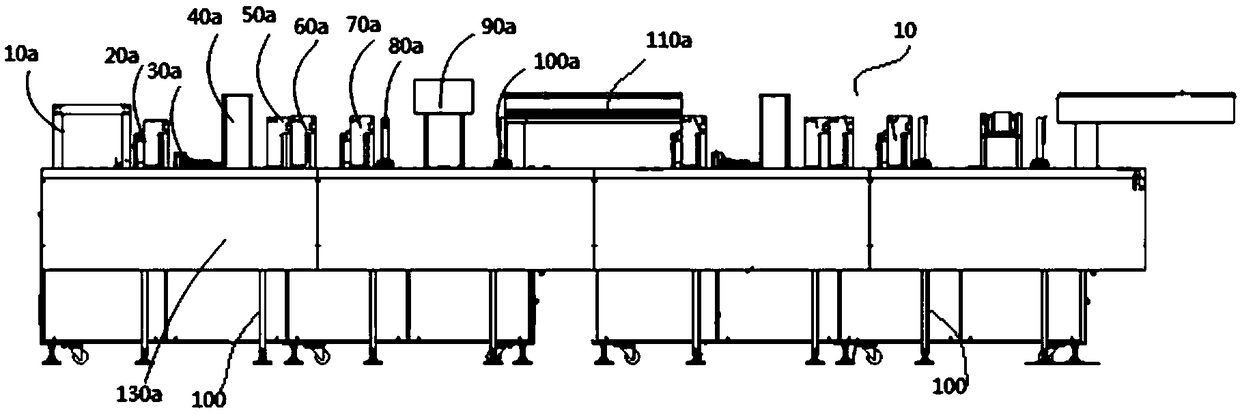

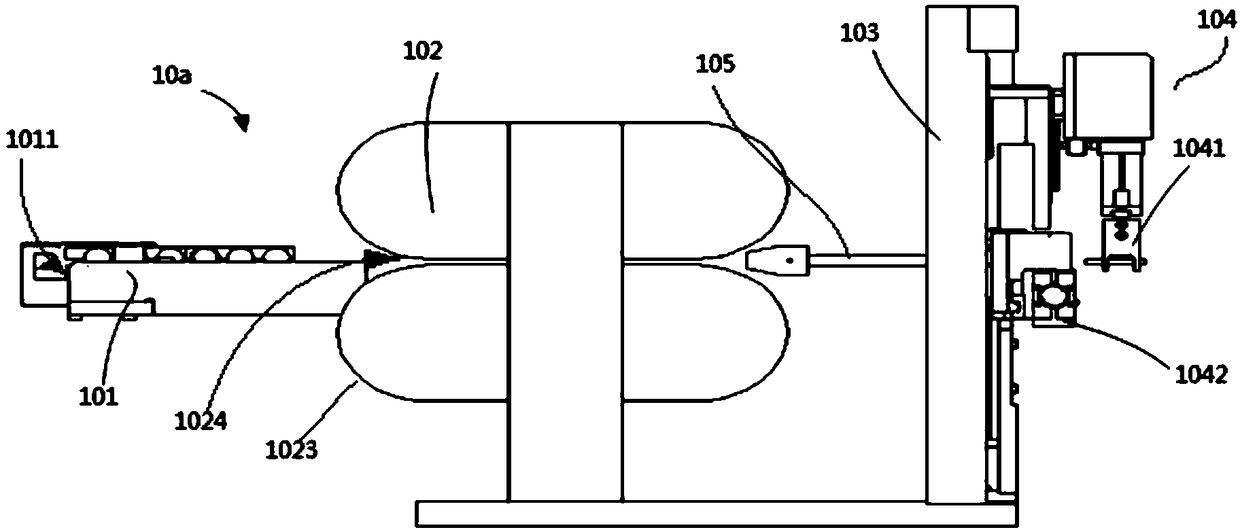

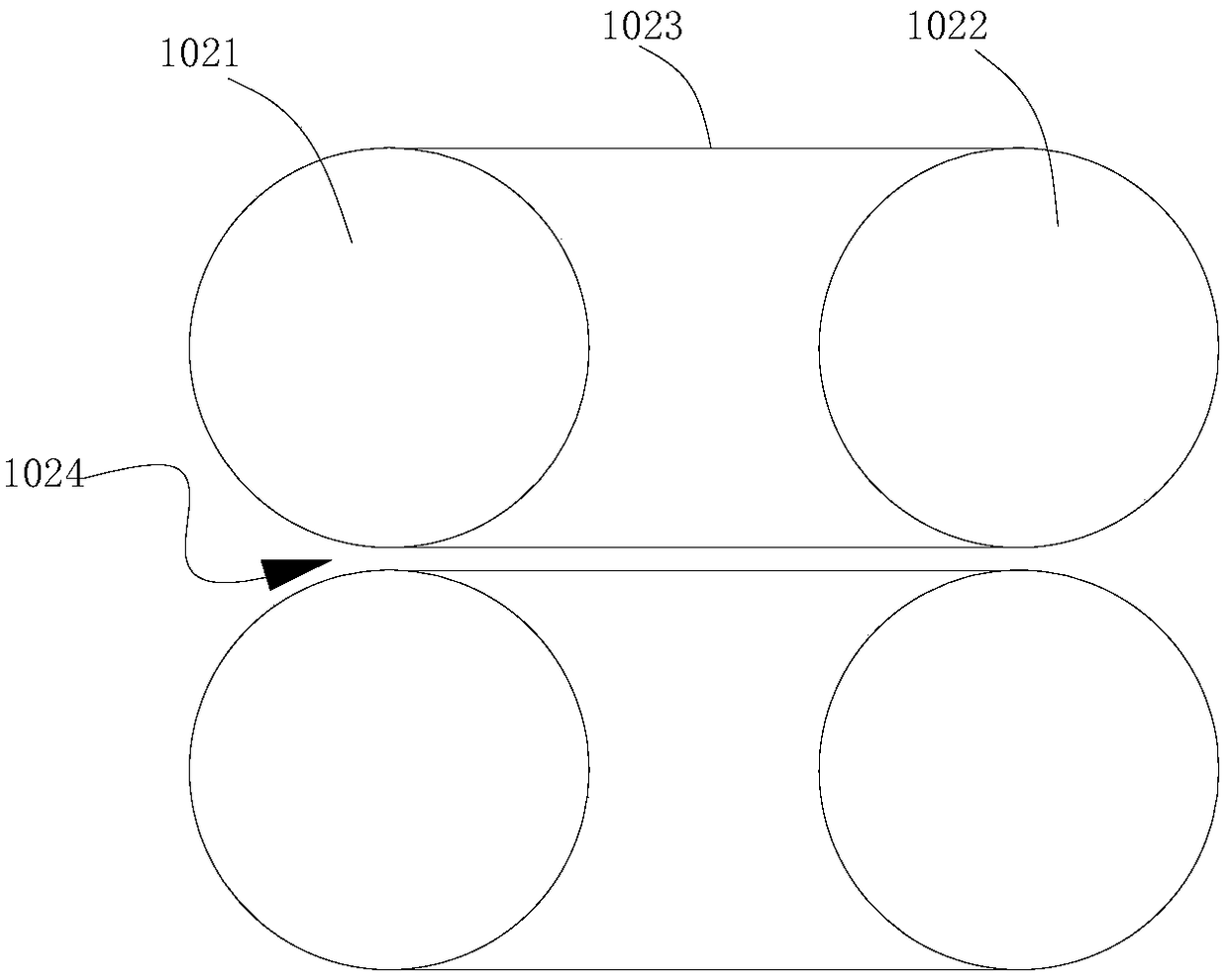

[0066] see figure 1 , the cable processing system includes at least one processing unit 10, each processing unit 10 forms an independent processing production line, each processing production line includes a strip-shaped base frame 100, installed on one side of the base frame 100 in the width direction and The fixed-length winding mechanism 10a, peeling mechanism 20a, talc powder removal mechanism 30a, polarity identification mechanism 40a, core wire separ...

Embodiment 2

[0105] see figure 1 , this embodiment provides a power cord assembly system, including a terminal crimping mechanism 90a, a crimping quality detection mechanism 100a, a blanking mechanism, and the cable processing system provided in Embodiment 1 above.

[0106] see Figure 24 The terminal crimping mechanism 90a includes a main frame body 900, a terminal conveying member 903, a core wire positioning and pressing assembly 902, and a core wire riveting assembly 901. The main frame body 900 is installed on the base frame 100, and the terminal conveying member 903 and the core wire The positioning and pressing assembly 902 is installed on the main frame body 900, and the terminal conveying member 903 is used to convey the terminal toward the riveting position of the core wire riveting assembly 901, and at the same time, the conveying mechanism 130a completes the externally stripped cable 1 to be processed. Transported to the riveting position, the core wire of the cable 1 to be pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com