Five degree-of-freedom bearingless switch reluctance motor

A switched reluctance motor, bearingless technology, applied to synchronous motors, synchronous machines, electromechanical devices for single-phase current, etc., can solve the problem of difficult to reflect the high speed and power density of bearingless motor technology, and the long axial length. , the problem of high critical speed, to achieve the effect of short axial length, less drive circuit and simple control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

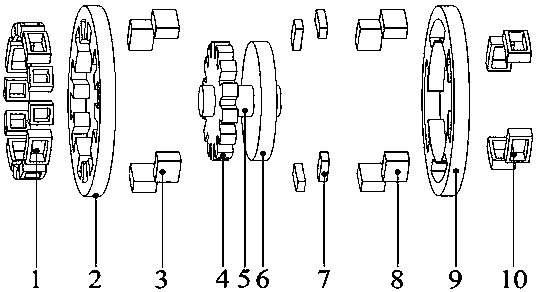

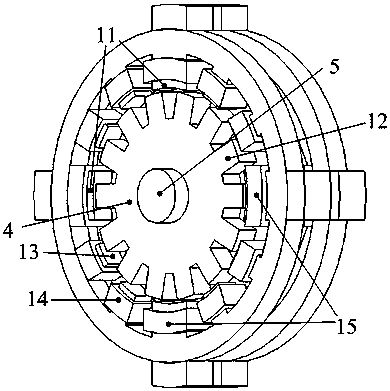

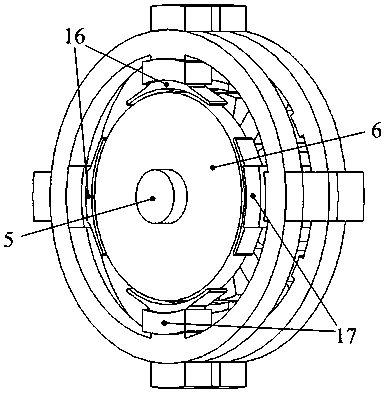

[0024] like Figures 1~4 A five-degree-of-freedom bearingless switched reluctance motor shown includes a common stator and a common rotor; the common rotor is composed of a motor rotor core 4 connected to a rotating shaft 5 and a magnetic bearing rotor core 6, and the motor rotor core 4 The rotor teeth 12 are arranged on the circumference of the motor; the common stator includes a motor stator core 2 and a magnetic bearing stator core 9 which are respectively arranged at intervals on the radial outer side of the motor rotor core 4 and the magnetic bearing rotor core 6. The motor stator core 2, The inner circumference of the magnetic bearing stator core 9 is provided with four motor suspension teeth 11 and four magnetic bearing suspension teeth 16 respectively in the x direction and the y direction. The motor suspension teeth 11 and the magnetic bearing suspension teeth 16 are respectively wound with suspension windings 15 and 17, torque teeth 13 are also arranged between the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com