Electromagnetic heating die

A mold, electromagnetic technology, applied in the direction of ohmic resistance heating, electric heating device, induction heating, etc., can solve the problems of infeasibility, inability to directly heat materials, unsatisfactory effect, etc., to achieve the effect of shortening the heating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

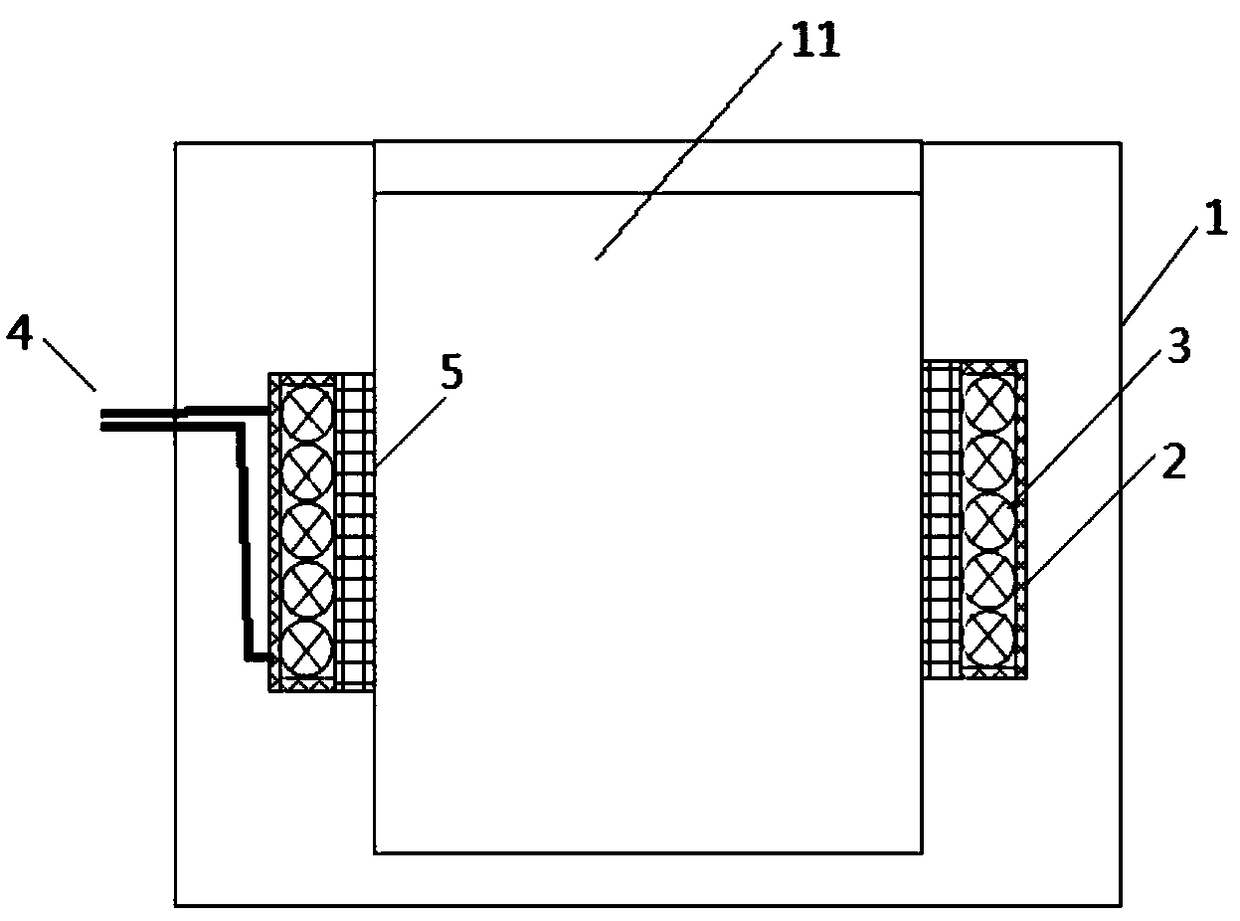

[0027] This embodiment provides an electromagnetic heating mold, such as figure 1 As shown, it includes a mold body 1 with a hollow cavity 11 suitable for placing the parts to be heated. The material of the mold body 1 can be selected from metallic materials or non-metallic materials. A containing groove is opened at a set position on the inner wall of the hollow cavity 11, and the opening of the containing groove faces the inside of the hollow cavity 11 and is arranged around the inner wall of the cavity 11. A magnetically conductive groove 2 is fixedly arranged in the receiving groove. The magnetically conductive groove 2 is made of a magnetically conductive ceramic material, and its opening faces the hollow cavity 11, and the magnetically conductive ceramic material has good insulation. It can confine the electromagnetic field within a certain range. Inside the magnetic conducting slot 2, a wire 4 is arranged. The conducting wire 4 is coiled inside the magnetic conducting sl...

Embodiment 2

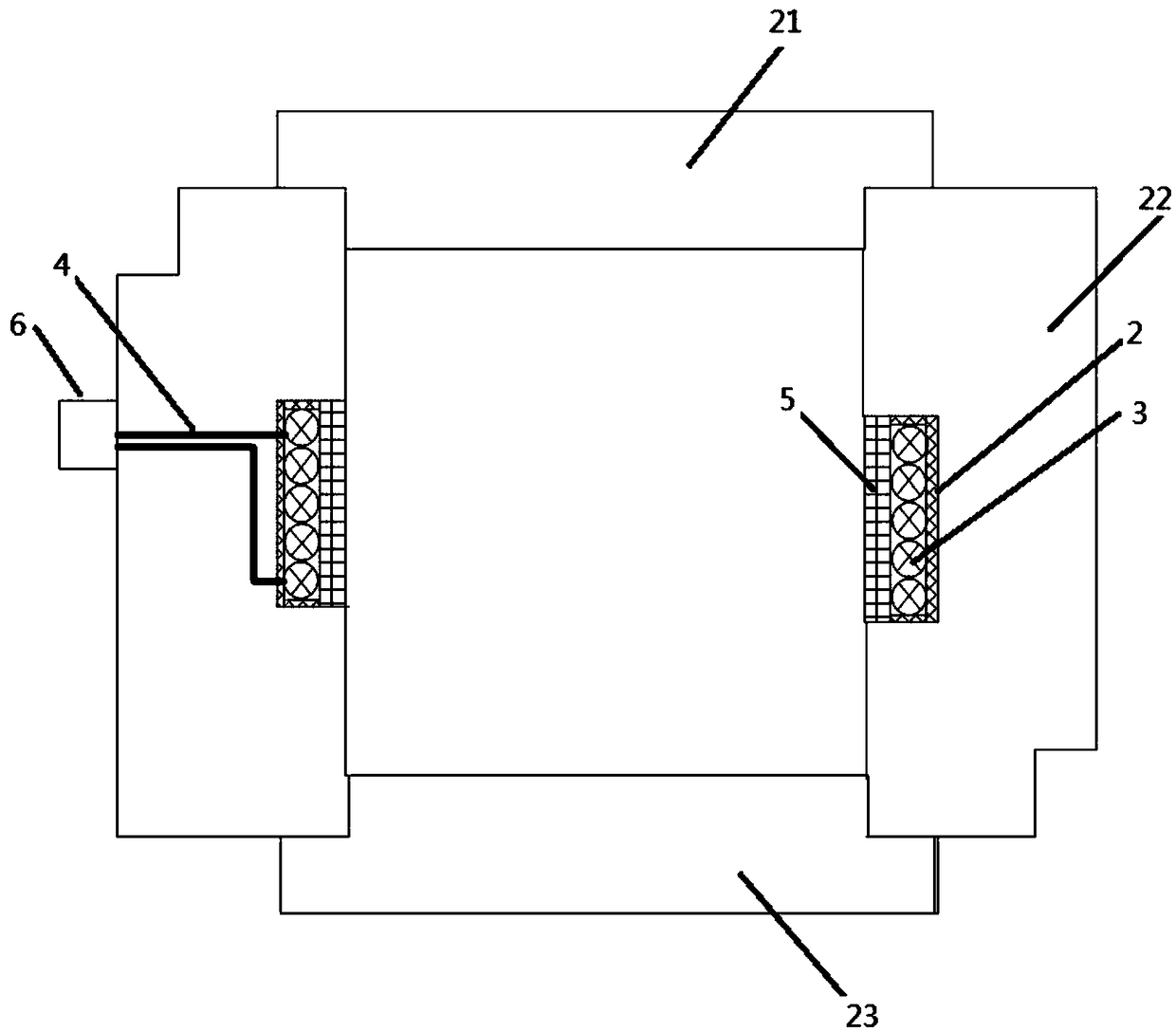

[0036] The electromagnetic heating mold provided in this embodiment, such as figure 2 As shown, the side wall of the mold body is provided with a connector 6; the two ends of the wire 4 pass through the magnetic groove 2 and the mold body and are electrically connected to the first end of the connector 6 The middle and high frequency power supply is electrically connected to the second end of the connector 6. The connector 6 can be realized by selecting an industrial waterproof connector, which can be products produced by manufacturers such as Chint Electric, Delixi Electric, etc.

[0037] Wire passage holes are opened on the bottom of the magnetic conductive groove 2 and the side wall of the hollow cavity 11; the wire inlet and outlet ends of the wire 4 pass through the wire hole and connect with the connector 6 The first end is connected; a sealant is poured between the wire 4 and the wire-through hole, so as to achieve the overall sealing of the mold.

[0038] In addition, in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com