Mask and method for manufacturing same

A manufacturing method and mask technology, applied in clothing, clothing, protective clothing, etc., can solve the problems of difficulty in selection, discomfort, and pressure, etc., to suppress workability, omit release paper, and resin cutting good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

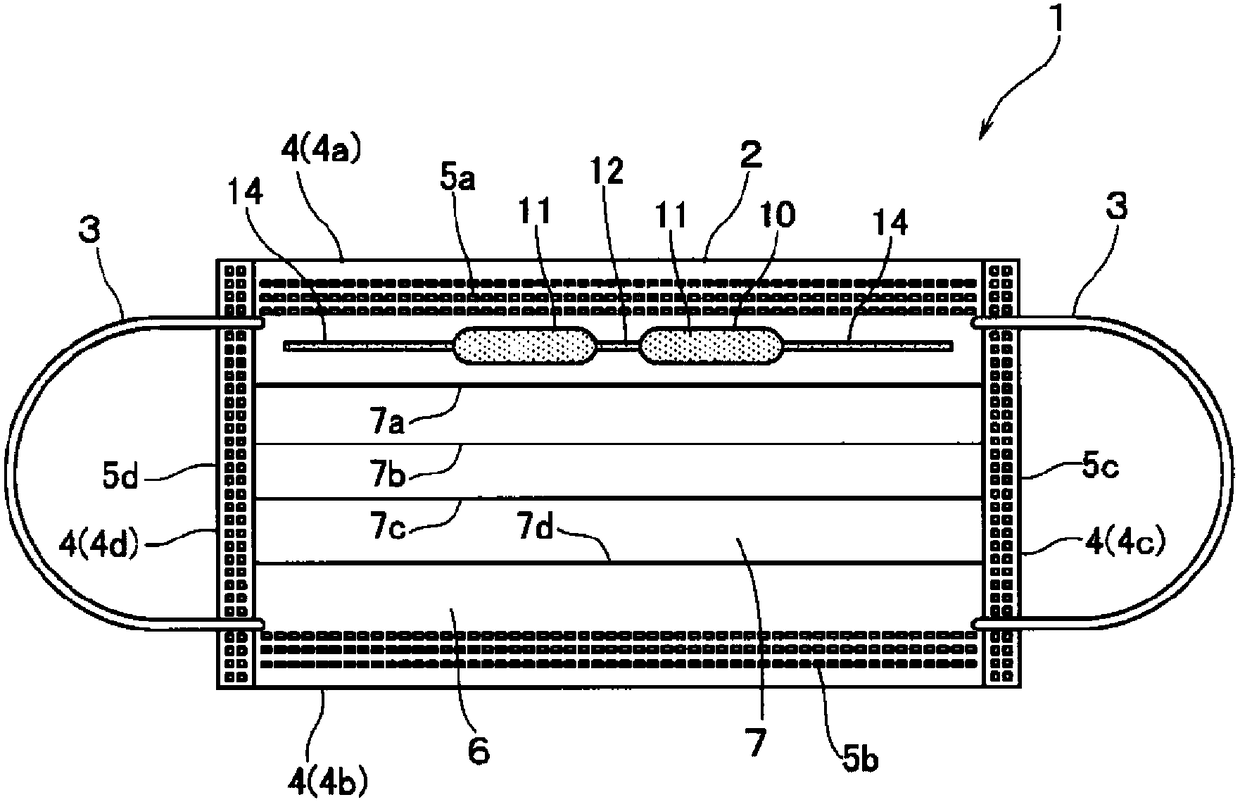

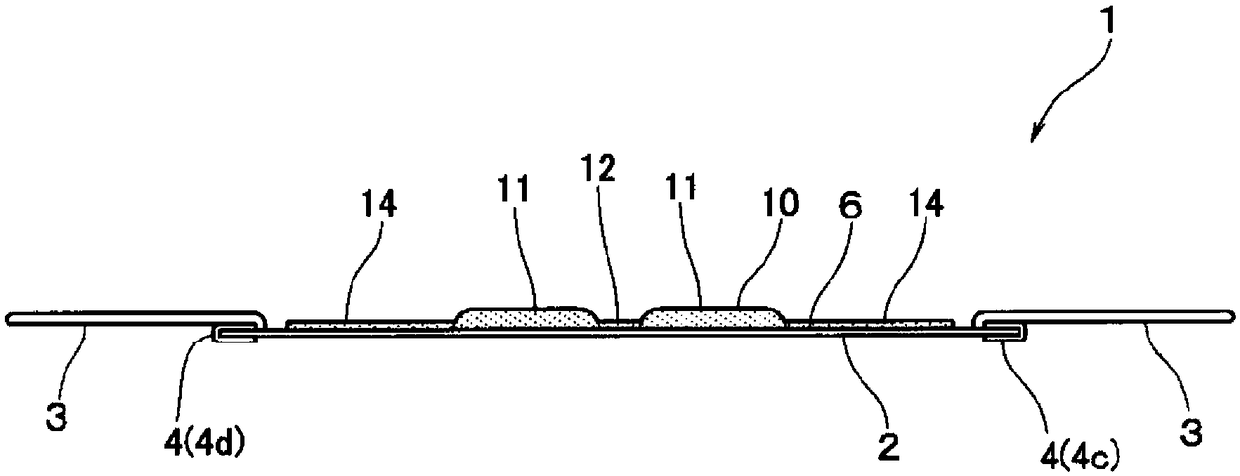

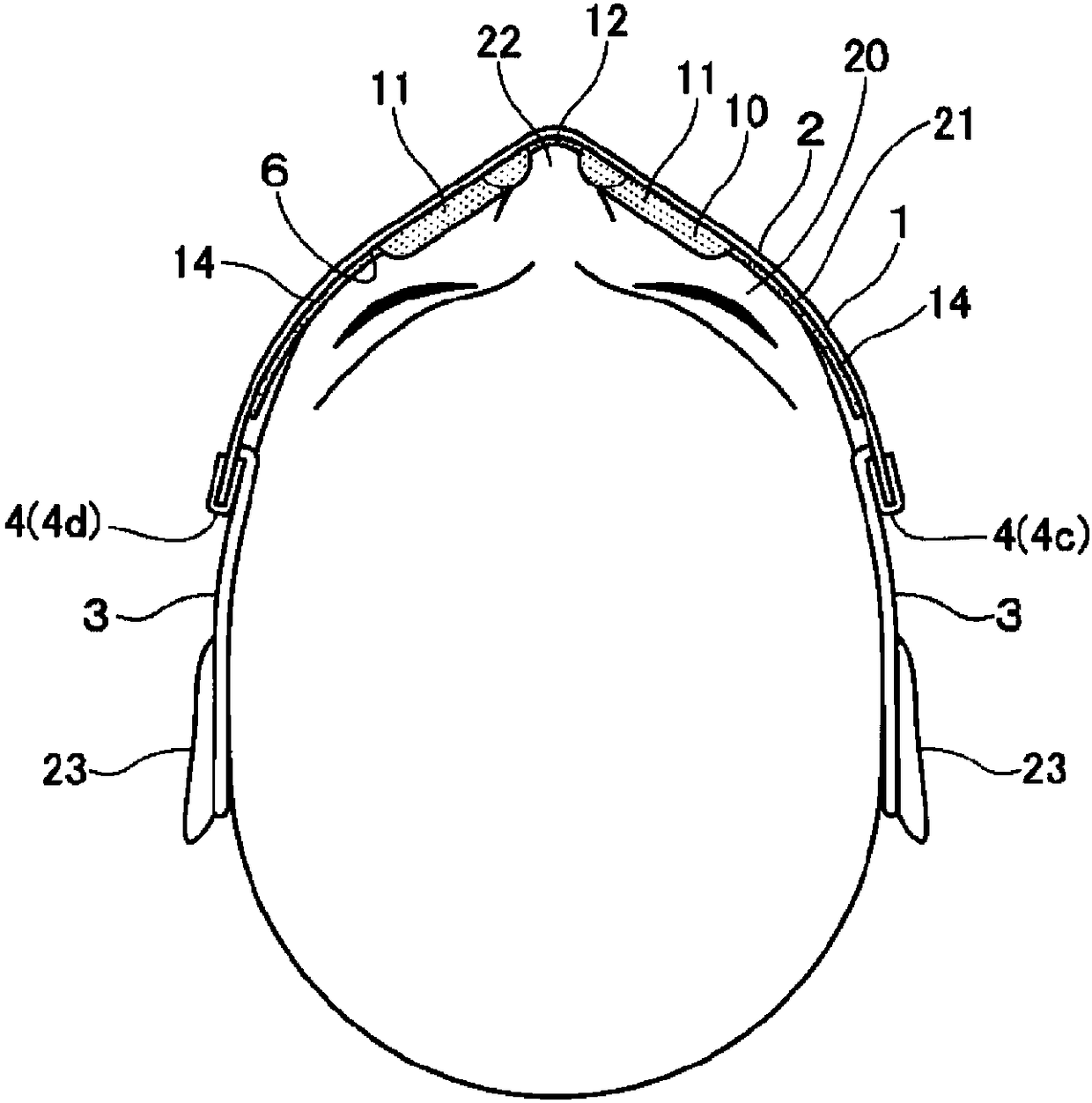

[0056] Figure 1 ~ Figure 3 One embodiment of the mask of this invention is shown. Figure 1 ~ Figure 3 The mask 1 of the present embodiment shown has: mask main body 2, as image 3 Shown is used to cover the face 21 (for example, the periphery of the mouth and nostrils) of the face 20 of the user;

[0057] Mask 1 is called a disposable so-called "pleated type", such as figure 1 As shown, a pleat 7 is provided near the center of the inner surface 6 of the mask 1 .

[0058] In this pleat part 7, a plurality of pleat crease parts 7a-7d which are folded with a predetermined width in the up-down direction of the mask main body 2 are formed in the width direction.

[0059] The creases 7a-7d are formed by folding the mask main body 2. When the mask main body 2 is opened up and down to unfold the folds 7, the mask main body 2 forms a mountain-shaped three-dimensional shape bulging outward.

[0060] The mask main body 2 has a quadrangular planar shape and is a laminate formed by o...

no. 2 approach

[0118] Figure 5 (a)-(d) is a figure for demonstrating one Embodiment of the manufacturing method of the mask of this invention.

[0119] In this embodiment, when the hot-melt material 10 is coated on the inner surface 6 of the mask 1 with the hot-melt spray gun 30, in the final process of coating, the function of the hot-melt spray gun 30 for spraying the hot-melt material 10 is closed. After the switch is turned off, the nozzle tip 30a of the hot melt spray gun 30 is in contact with the inner surface 6 of the mask 1 near the coating end of the hot melt material 10 .

[0120] Such as Figure 5 As shown in the front view observed from the side of the mask of (a), the hot-melt material 10 after heating and melting is applied to the inner surface 6 of the mask main body 2, and in the final process of coating using the hot-melt spray gun 30 , at position A, close the switch of the hot melt spray gun 30 to eject the hot melt material 10 . At this time, if Figure 5 As shown in...

no. 3 approach

[0124] Figure 6 ~ Figure 8 Another embodiment of the mask of the present invention is shown. In addition, the same code|symbol is attached|subjected to the part common to the said 1st Embodiment, and detailed description is abbreviate|omitted.

[0125] Such as Figure 6 As shown, for the mouth mask 1 of the present embodiment, near the upper end 4a of the peripheral edge 4, two upper end side thick parts 11, 11 and two upper end side thick parts 11 and 11 that are attached to the both sides of the nose 22 are provided near the upper end 4a of the periphery 4. The constricted part 12 between 11 and 11 is provided in a linear shape on the side opposite to the constricted part 12 of the upper thick part 11 and 11, and the upper thin parts 14 and 14 are respectively directed toward the side ends 4c and 4d.

[0126] These upper end side thick parts 11, 11, narrowed part 12 and upper end side thin parts 14, 14 form the upper end side thick part 11 and upper end side thin part 14 fr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt viscosity | aaaaa | aaaaa |

| Melt viscosity | aaaaa | aaaaa |

| Melt viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com