Fly ash stabilizing treatment device

A technology for stabilizing fly ash, which is applied in the field of fly ash processing, can solve the problems that the mixing device cannot be easily disassembled, cannot achieve a stable effect, and the mixture is not stable enough, so as to avoid poor stirring effect, convenient preparation, and easy and convenient cleaning Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further clarified below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the following specific embodiments are only used to illustrate the present invention and not to limit the scope of the present invention. Modifications of various equivalent forms fall within the scope defined by the appended claims of this application.

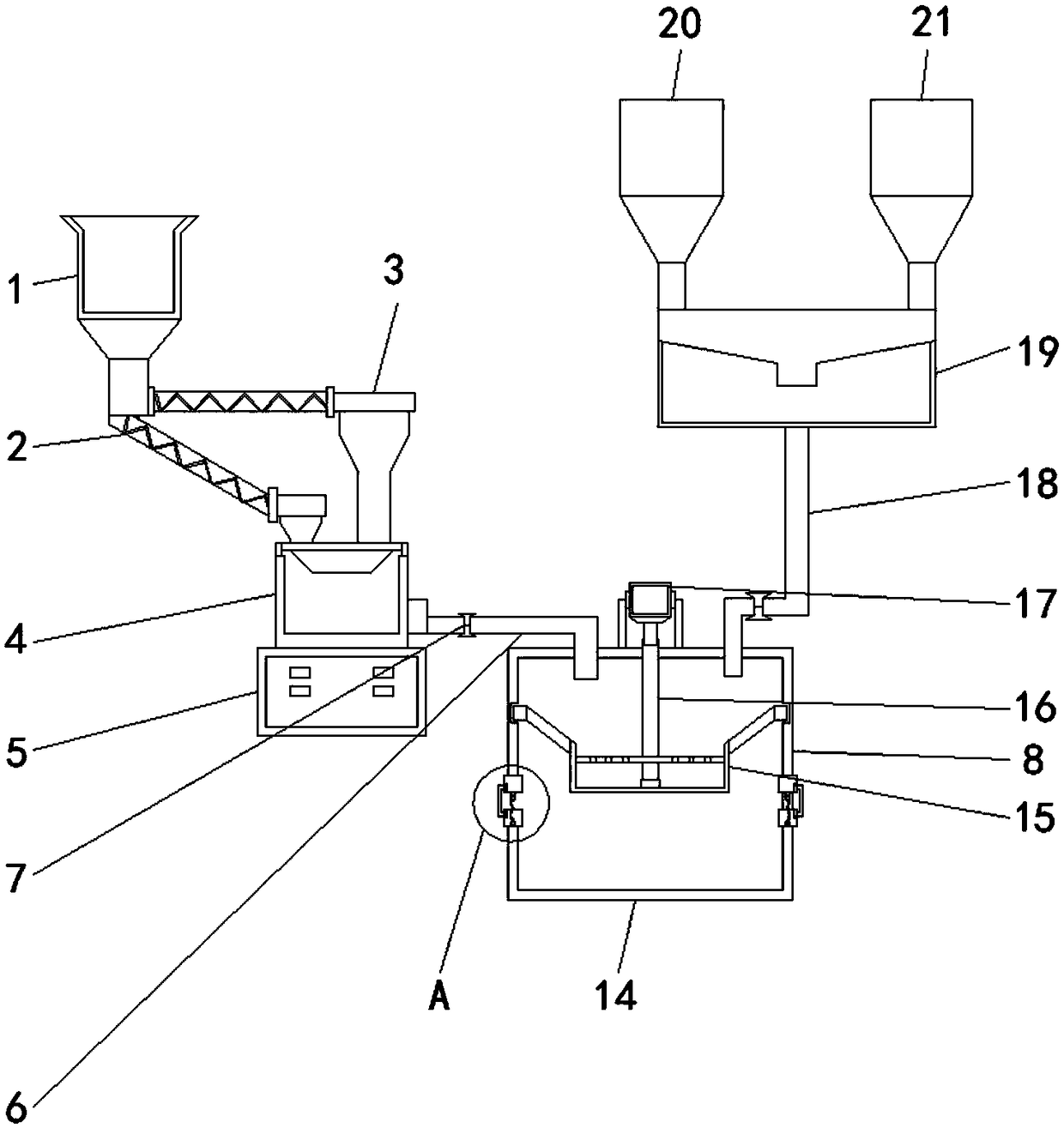

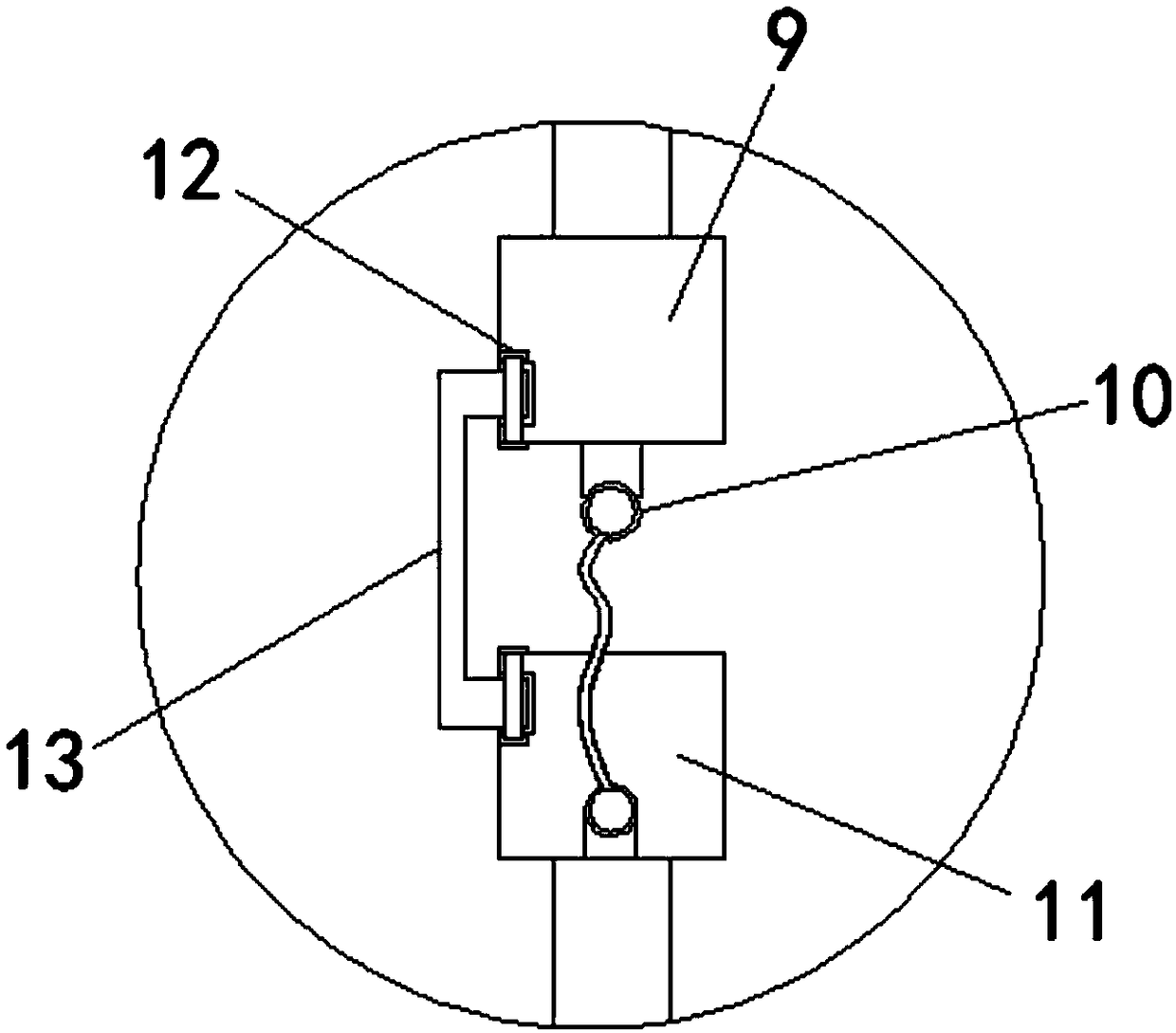

[0022] see Figure 1-2 , a fly ash stabilization treatment device, comprising a hopper 1, a screw conveyor 2 is fixedly installed at the bottom end of the hopper 1, and the fly ash enters the interior of the screw conveyor 2 through the conveying box 1 and then enters the conveying pipeline 3, because the conveying pipe 3 is fixedly connected with the weighing bucket 4, so the fly ash enters the inner wall of the weighing bucket 4, and is weighed by the weighing device 5. The first weighing box 20 and the second weighing box In the inner wall of 21 , the chelating a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com