Gear extrusion forming device

A technology of extrusion molding and gears, which is applied in the direction of wheels, transportation and packaging, vehicle parts, etc., can solve problems such as deformation and unfavorable gear sales, and achieve the effects of reducing time, avoiding deformation and wear, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

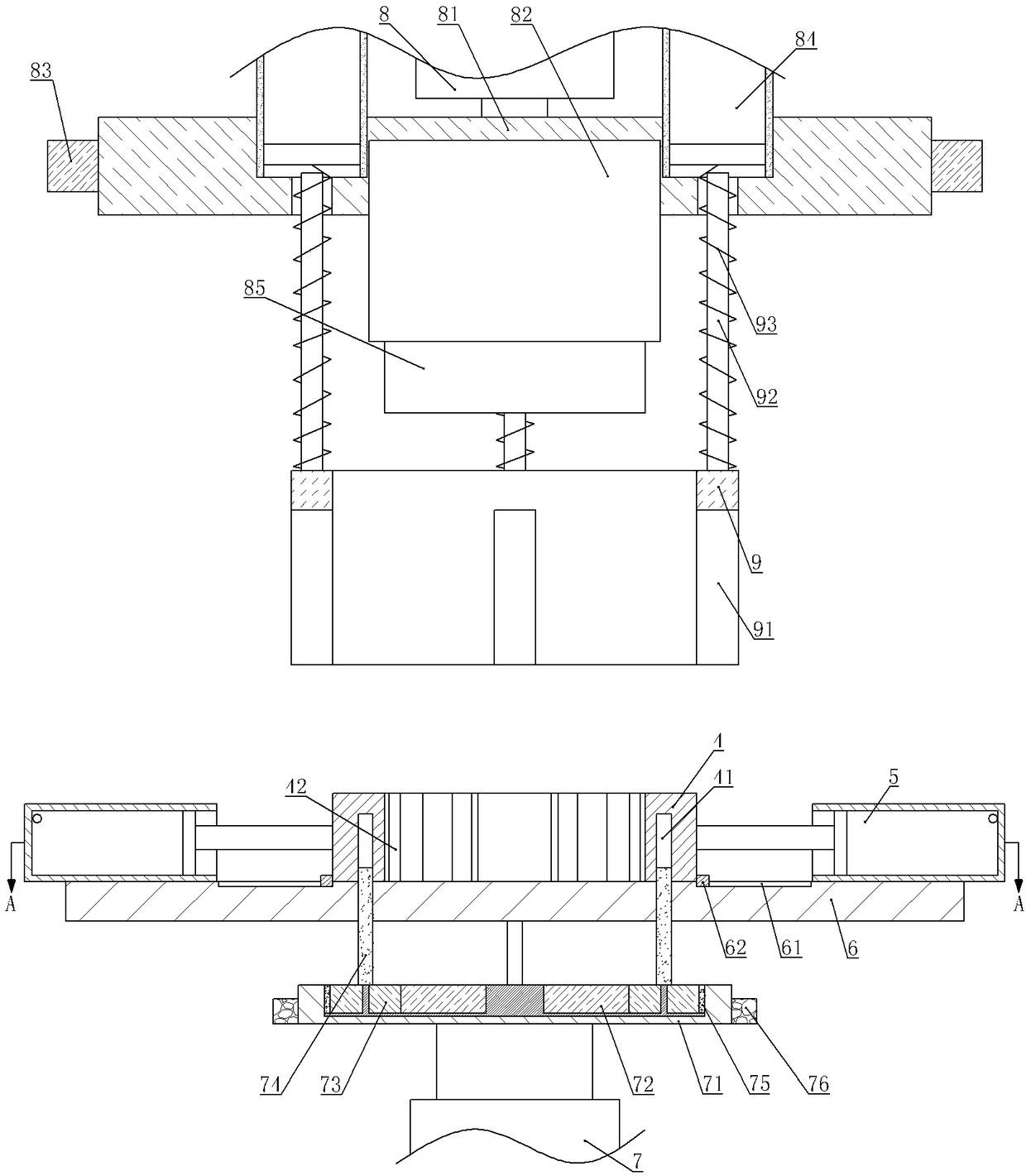

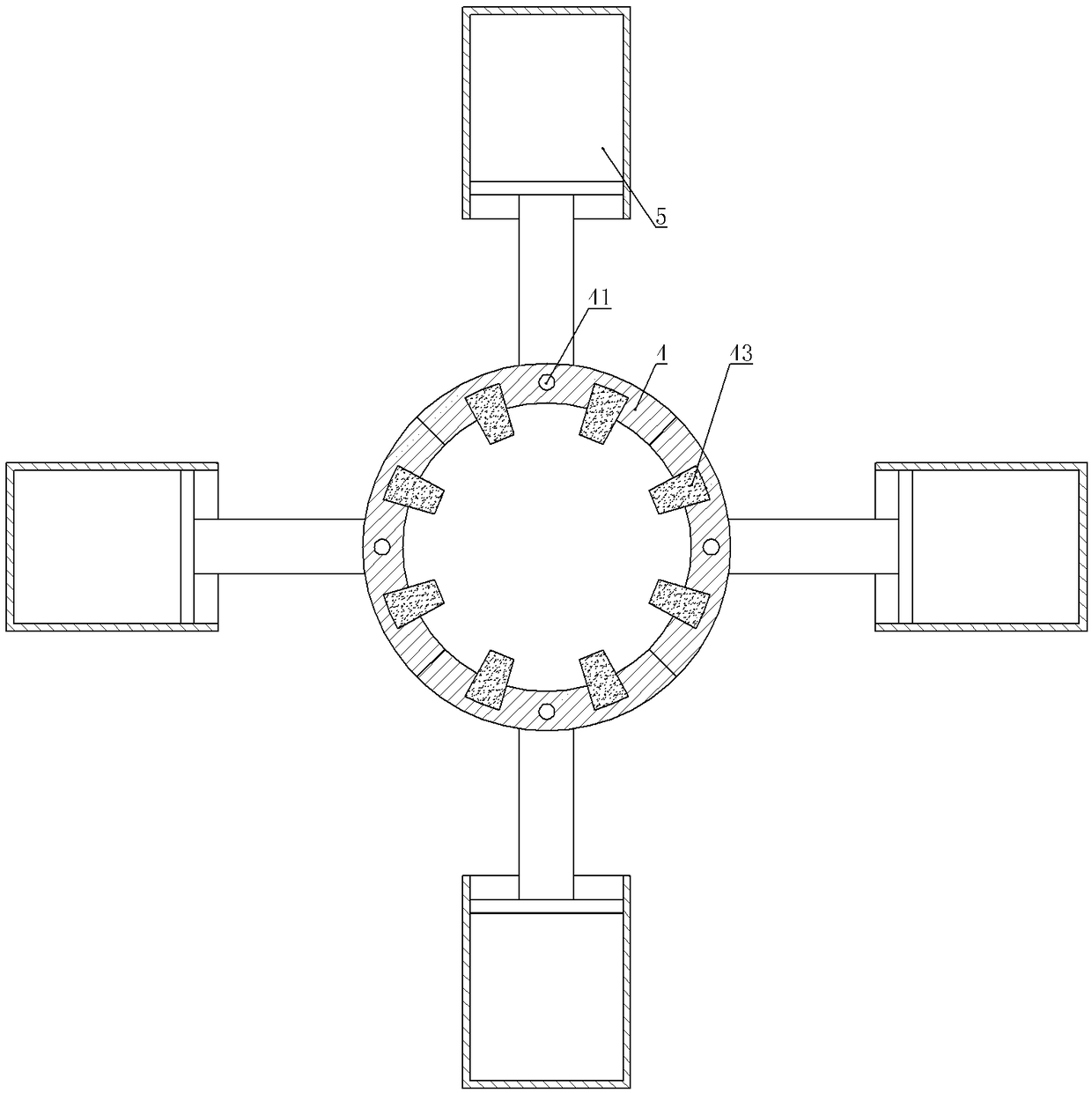

Method used

Image

Examples

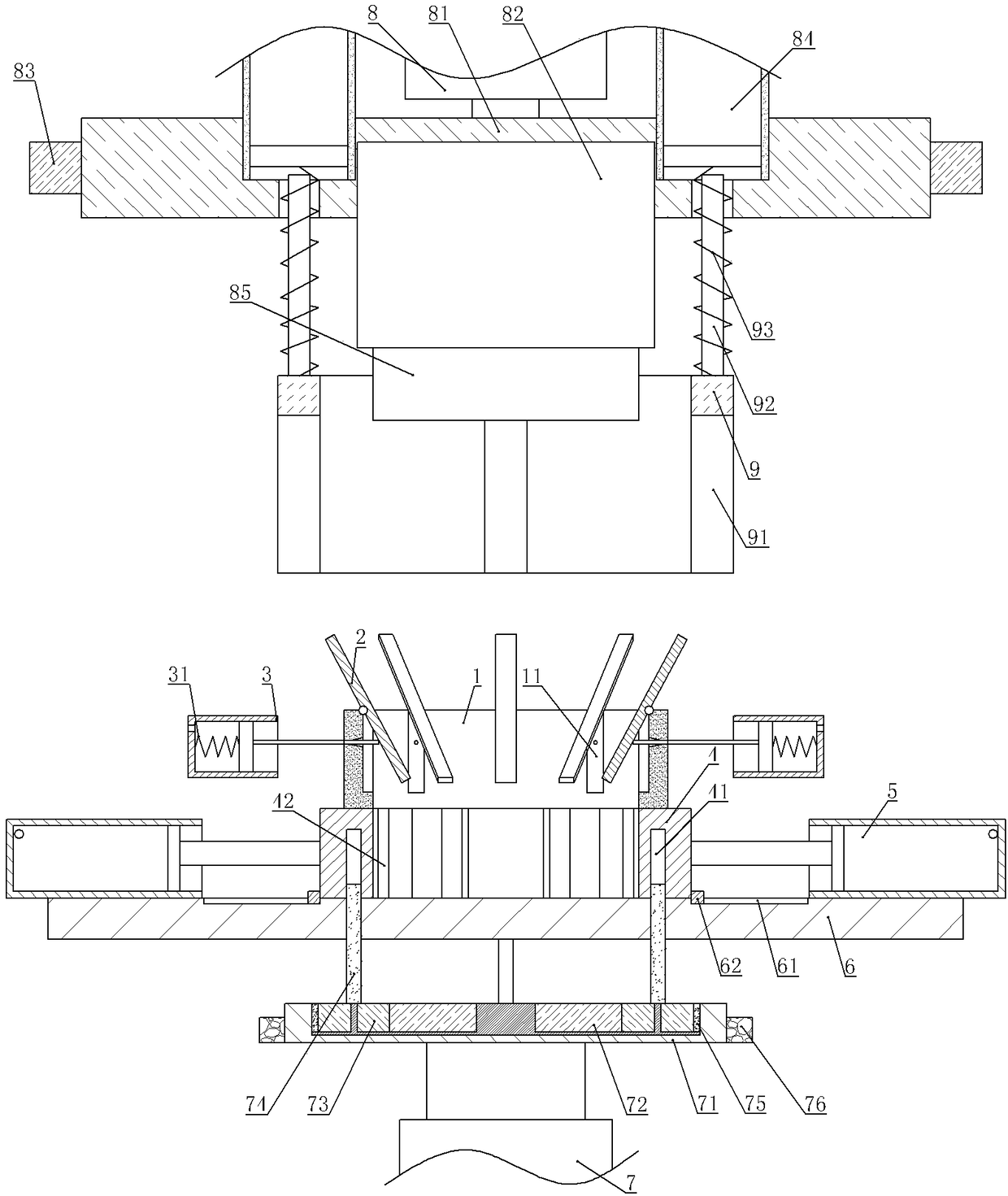

Embodiment 2

[0037] The difference from Example 1 is that, as image 3 As shown, a support mechanism is also provided between the arc block 4 and the limit ring 9, and the support mechanism includes a feed cylinder 1 welded on the frame 6, eight support cylinders 3 and a hinged joint with the top of the feed cylinder 1. There are eight support pieces 2 , and the inner wall of the feeding cylinder 1 is provided with accommodating grooves 11 that can accommodate the support pieces 2 . The piston rod of the support cylinder 3 runs through the feeding cylinder 1 and is offset against the lower part of the support plate 2. When the limit ring 9 slides downward, the piston rod of the support cylinder 3 is snapped into the passage groove 91, and the support cylinder 3 is provided with two ends The return spring 31 welded on the inner wall of the support cylinder 3 and the piston of the support cylinder 3 respectively, and the end of the support cylinder 3 away from the support plate 2 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com