Vessel tank, tank container, horizontal-type storage tank, highway tanker, and railway tanker

A container tank and inner container technology, which is applied in the field of storage and transportation equipment, can solve problems such as failure of the support part of the low temperature container tank body, and achieve the effects of enhancing stability, improving stress distribution, and solving failure risks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

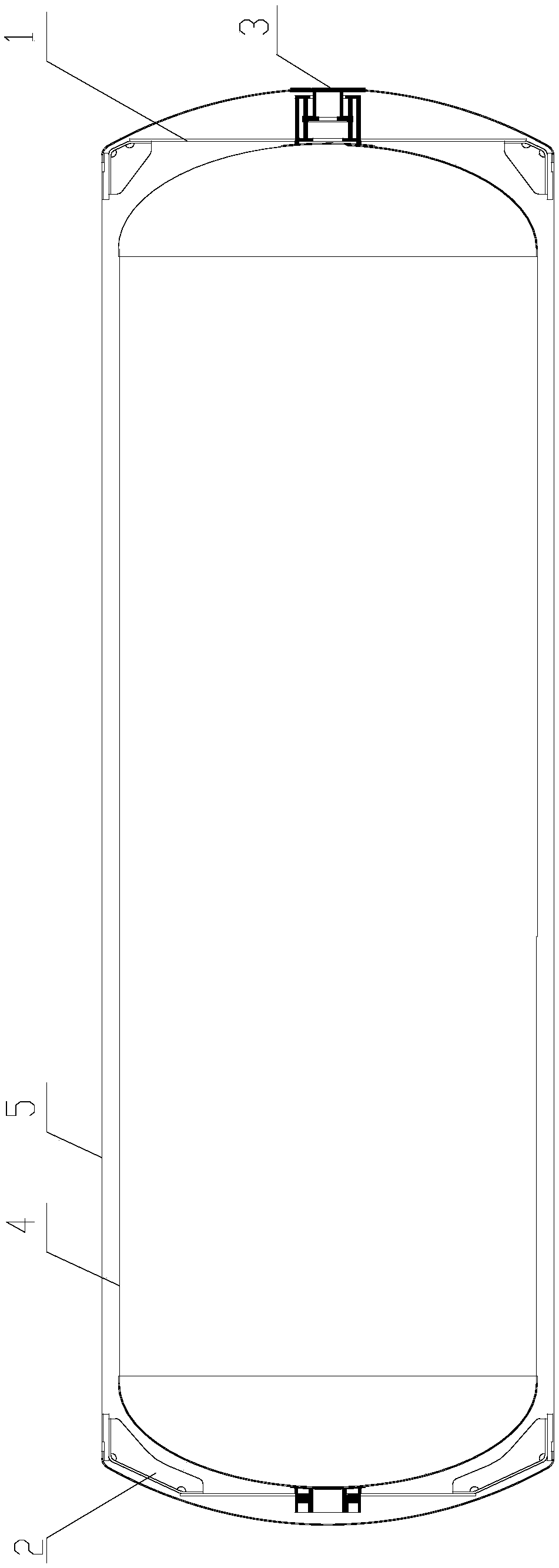

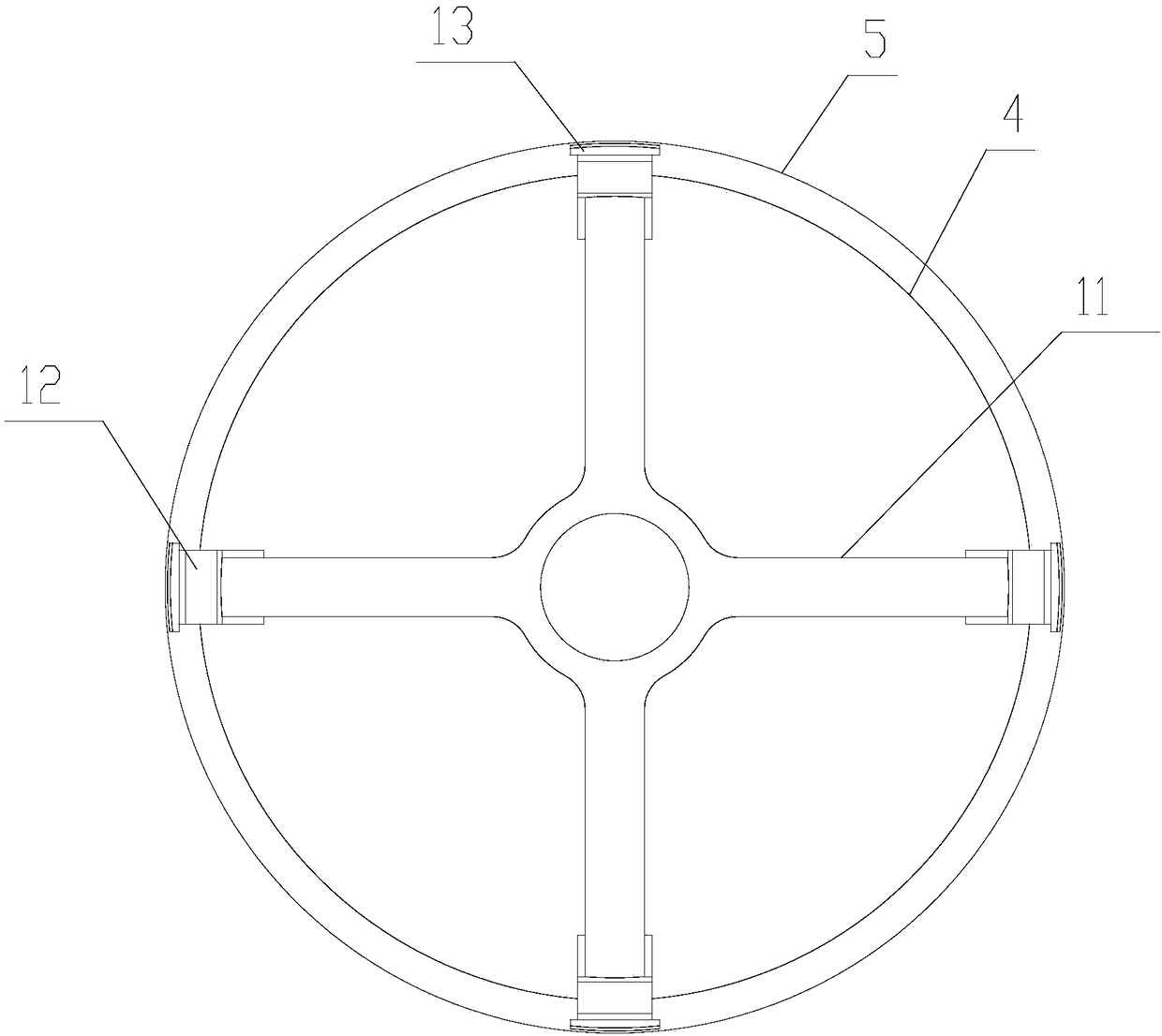

[0059] See attached figure 1 , the present embodiment provides a container body, including an inner container 4 and an outer shell 5, and the inner container 4 and the outer shell 5 are arranged coaxially; the container body also includes: a fixed end sling device 1 and a sliding end sling device 2 ,in:

[0060] The fixed-end sling device 1 is arranged between the head of one end of the outer shell 5 and the head of the inner container 4 corresponding to the end of the outer shell 5, and the fixed-end sling device 1 is connected to the head of the inner container 4 to transfer a part of the weight of the inner container 4 on the shell 5; the sliding end sling device 2 is arranged between the head of the other end of the shell 5 and the head of the inner container 4 corresponding to the end of the outer shell 5, the sliding end sling device 2 is connected to the head of the inner container 4, and the contents The remaining weight of the device 4 is transferred to the shell 5. ...

Embodiment 2

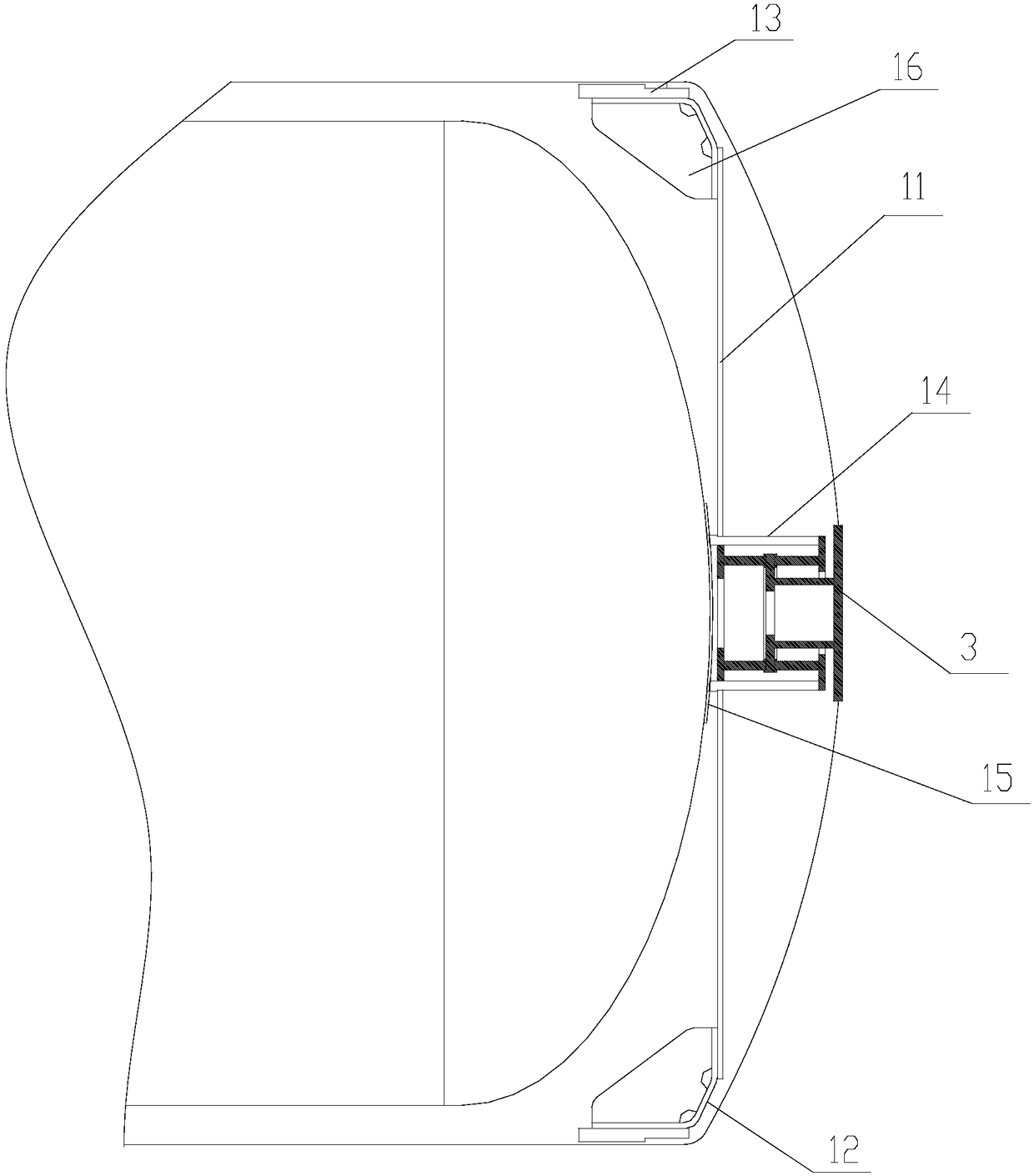

[0079] See attached figure 1, the container body provided in this embodiment not only includes the inner container 4, the outer shell 5, the fixed end sling device 1 and the sliding end sling device 2 in the first embodiment, but also includes a longitudinal displacement restraining device 3, which is arranged close to the sliding end sling device 2 , see attached Figure 10 and 11 , the longitudinal displacement restraint device 3 includes: a blocking plate 31, a connecting pipe 32, a mounting plate 33, a first limiting plate 34, a second limiting plate 35, a first glass steel pipe 36 and a second glass steel pipe 37, wherein:

[0080] The blocking plate 31 is fixedly connected with the right end head of the shell 5; one end of the connecting pipe 32 is fixedly connected with the blocking plate 31, and the other end is fixedly connected with the mounting plate 33; one side of the mounting plate 33 is provided with a first annular groove 331, and the other The side is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com